A kind of preparation method of super absorbent resin for sanitary napkin

A high-absorbency, sanitary napkin technology, applied in the field of fine chemicals, can solve the problems of hindering blood diffusion and absorption, poor blood absorption effect of resin, etc., and achieve the effects of improving affinity, improving curing rate, and improving roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

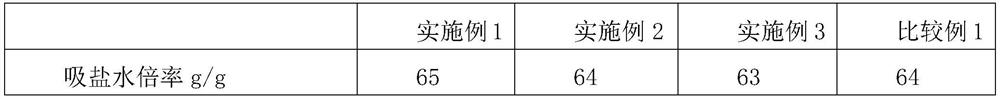

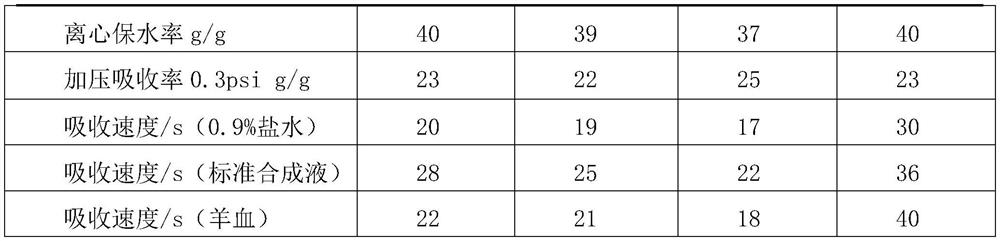

Embodiment 1

[0056] Add 100.00 parts of refined acrylic acid and 125.00 parts of water to the reactor, then add 86.8 parts of 48% concentration NaOH for neutralization, then add 1.025 parts of crosslinking agent polyethylene glycol 400 diacrylate, foam stabilizer carboxymethyl cellulose 1.25 parts of sodium, 0.2 part of sodium oxalate, an anticoagulant, compressed air was introduced from the bottom of the reactor, the inner diameter of the ventilation outlet was 5 mm, and the flow rate was 2.0 L / min. After 10 minutes, the reaction solution was cooled and heated to 80 ° C. Add initiator: 50wt% 0.8 part of sodium persulfate. After the polymerization reaction was completed, crushing and granulation were carried out, and 15 parts of SAP fine powder was added during granulation. After granulation, it is dried, and the dried material is crushed and sieved to control the particle size of 45-300 μm, and the mass ratio is 80%. After that, the surface treatment is carried out. The surface treatment...

Embodiment 2

[0058] Add 100.00 parts of refined acrylic acid and 103.00 parts of water to the reactor, then add 90.0 parts of 48% concentration NaOH for neutralization, and then add 0.815 parts of crosslinking agent polyethylene glycol 400 diacrylate, polyethylene glycol 1000 diacrylate 0.320 part, foam stabilizer SAP fine powder 0.5 part, anticoagulant disodium EDTA 0.32 part, nitrogen was introduced from the bottom of the reactor, the inner diameter of the vent was 2mm, and the flow rate was 2.0L / min. The temperature was lowered to 80° C., and an initiator: 0.4 part of 50 wt % sodium persulfate was added. After the polymerization reaction was completed, crushing and granulation were carried out, and 20 parts of SAP fine powder were added during granulation. After granulation and drying, the dried material is crushed and sieved to control the particle size of 45-300μm, and the mass ratio is 83%. After that, the surface treatment is carried out. The surface treatment liquid is prepared fr...

Embodiment 3

[0060] Add 100.00 parts, 90.00 parts of refined acrylic acid to the reactor, then add 86.8 parts of 48% concentration NaOH for neutralization, then add 1.025 parts of crosslinking agent polyethylene glycol 400 diacrylate, 1.1 parts of foam stabilizer SAP fine powder, 0.31 part of sodium oxalate, an anticoagulant, was introduced into compressed air from the bottom of the reactor, the inner diameter of the vent was 2 mm, and the flow rate was 2.0 L / min. After 10 minutes, the reaction solution was cooled and heated to 80 °C, and the initiator was added: 50wt% sodium persulfate 0.4 share. After the polymerization reaction was completed, crushing and granulation were carried out, and 15 parts of SAP fine powder was added during granulation. After granulation, it is dried, and the dried material is crushed and sieved to control the particle size of 45-300μm, and the mass ratio is 90%. After that, surface treatment is carried out. The surface treatment liquid is prepared by ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com