Method for producing brandy and enzyme from distilled residual liquid of brandy by distilling compound fruit wine

A compound fruit wine and brandy technology, applied in the field of food processing, can solve the problems of unqualified, high alcohol content of enzyme products, affecting the quality of enzyme products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

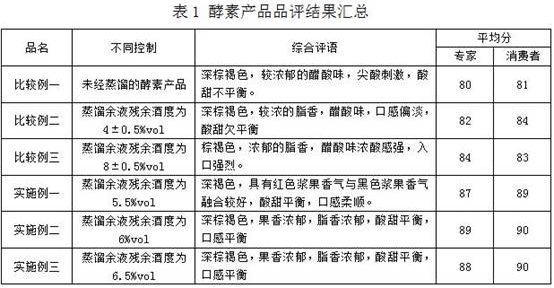

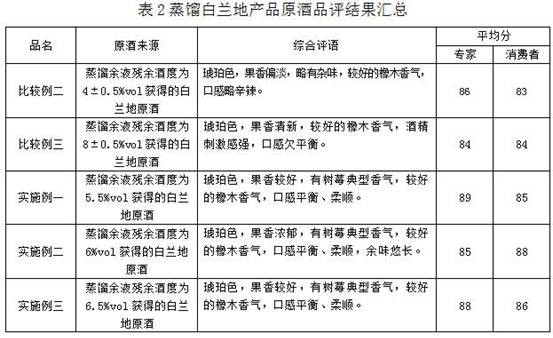

Examples

Embodiment 1

[0046] A method for producing brandy by distillation of compound fruit wine and its distillate residue to produce enzymes, comprising the following steps:

[0047] S1, preparing raw wine fermentation liquid

[0048] Weigh the following raw materials: 350kg red raspberry, 250kg blackberry, 100kg mulberry, 70kg wolfberry, 100kg black currant; put the above raw materials into the fermenter after crushing; dipping and pectinase treatment before low temperature; add yeast for alcohol fermentation, alcohol After the fermentation, the solid-liquid separation was carried out, and after 7 days of sedimentation, the tank was poured to obtain 540L of 12.3%vol original wine fermentation liquid.

[0049] S2, alcohol distillation

[0050] Use the Charente distillation equipment to distill the original wine fermentation liquid after alcohol fermentation, calculate the alcohol content of the head and middle distillate wine according to the initial alcohol content of the original wine ferment...

Embodiment 2

[0057] A method for producing brandy by distillation of compound fruit wine and its distillate residue to produce enzymes, comprising the following steps:

[0058] S1, preparing raw wine fermentation liquid

[0059] Weigh the following raw materials: 100kg of red raspberry, 250kg of blackberry, 350kg of mulberry, 70kg of wolfberry, 100kg of black currant; crush the above raw materials and put them into the fermenter; dipping and pectinase treatment before low temperature; add yeast for alcohol fermentation, alcohol Solid-liquid separation was carried out at the end of the fermentation, and 540L of 12.0%vol original wine fermentation liquid was obtained by inverting the tank after 7 days of sedimentation.

[0060] S2, alcohol distillation

[0061] Use the Charente distillation equipment to distill the original wine fermentation liquid after alcohol fermentation, calculate the alcohol content of the wine head and middle distillate wine according to the initial alcohol content o...

Embodiment 3

[0068] A method for producing brandy by distillation of compound fruit wine and its distillate residue to produce enzymes, comprising the following steps:

[0069] S1, preparing raw wine fermentation liquid

[0070] Weigh the following raw materials: 450kg red raspberry, 250kg blackberry, 50kg mulberry, 20kg wolfberry, 100kg black currant; put the above raw materials into the fermentation tank after crushing; dipping and pectinase treatment before low temperature; add yeast for alcohol fermentation, alcohol Solid-liquid separation was carried out at the end of the fermentation, and after 7 days of sedimentation, the tank was inverted to obtain about 540L of 11.8%vol original wine fermentation liquid.

[0071] S2, alcohol distillation

[0072] Use the Charente distillation equipment to distill the original wine fermentation liquid after alcohol fermentation, calculate the alcohol content of the head and middle distillate wine according to the initial alcohol content of the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com