Multifunctional organ chip based on microfluidic technology, preparation method and application thereof

A microfluidic technology, organ chip technology, applied in stress-stimulated microbial growth methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve problems such as difficult to correctly reflect human cornea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

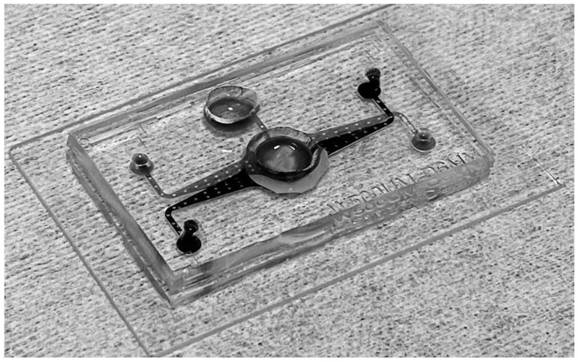

[0092] A multifunctional organ chip based on microfluidic technology, see Figure 1-Figure 4 as well as Figure 9 . see figure 1 , the chip comprises two structural layers, the upper layer 1 is the upper layer 1 polydimethylsiloxane (Polydimethylsiloxane, PDMS) with the first microchannel 4, the first cell culture area 5 and the first test area 9, and the lower layer porous membrane 8 is a polycarbonate membrane with a microporous structure, the lower layer 2 is a lower layer 2PDMS with a second microchannel 6, a second cell culture area and a second test area 10, and the substrate 3 is a glass-based substrate.

[0093] see figure 2 , the upper left corner and the lower right corner of the chip of the present invention are the inlet and the outlet of the first microchannel 4 respectively, the lower left corner and the upper right corner of the chip are respectively the inlet and the outlet of the second microchannel 6; the three-dimensional cell culture area in the middle ...

Embodiment 2

[0099]A preparation method of a multifunctional organ chip based on microfluidic technology: taking two structural layers as an example:

[0100] The chip manufacturing process includes three parts: upper layer 1PDMS manufacturing, lower layer 2PDMS manufacturing and chip bonding, such as Figure 5 shown. The manufacturing steps of the upper layer 1 PDMS include: making the upper layer 1 microchannel male mold, pouring the upper layer 1 PDMS, turning over the upper layer 1 PDMS, and punching the upper layer 1 PDMS, see Figure 5 Neutron Figure S1. The manufacturing steps of the lower layer 2PDMS include: making the lower layer 2 microchannel male mold, lower layer 2PDMS pouring, lower layer 2PDMS turning over, and lower layer 2PDMS drilling, see Figure 5 Neutron Figure S2. Then, first bond the lower layer 2PDMS to the glass substrate, then seal the second cell culture area 7 of the lower layer 2PDMS with a polycarbonate film, and finally align and bond the upper layer 1PDM...

Embodiment 3

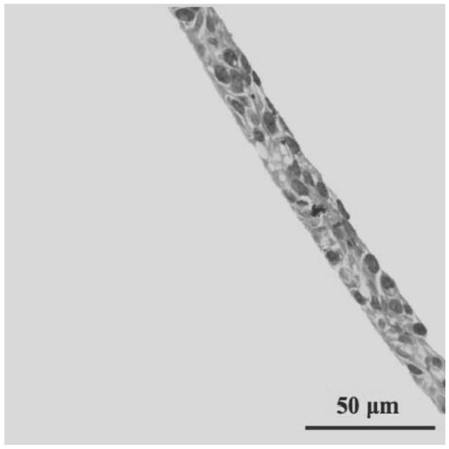

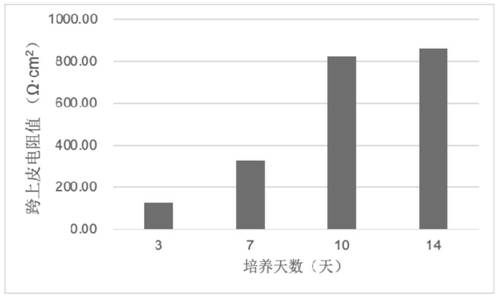

[0125] The multifunctional organ chip based on microfluidic technology of the present invention can be used to construct human organs. The following uses the human cornea as an example to illustrate:

[0126] A method for simulating the physiological microenvironment of the human eye with a multifunctional organ chip based on microfluidic technology, comprising the following steps:

[0127] The microenvironment of the human cornea can be simulated by using the above-mentioned organ chip. This part will introduce the construction method and operation steps of the eye organ chip in detail, mainly including chip pretreatment, three-dimensional cell culture, sample collection, analysis and characterization. The flow chart is as follows: Figure 7 shown.

[0128] Sub-step C1, chip pretreatment:

[0129] The microfluidic chip is sterilized by ultraviolet irradiation for more than or equal to 30 minutes in a clean bench, and the chip is modified by adding type 1 collagen, placed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com