Composite flower extract and application thereof in cosmetics

A technology for flower extraction and chrysanthemum, which is applied to compound flower extracts and their application fields in cosmetics, can solve the problems that plant extracts have not been produced on a large scale, have not been combined and obtained oil-soluble extracts, etc. The effect of convenient material acquisition and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

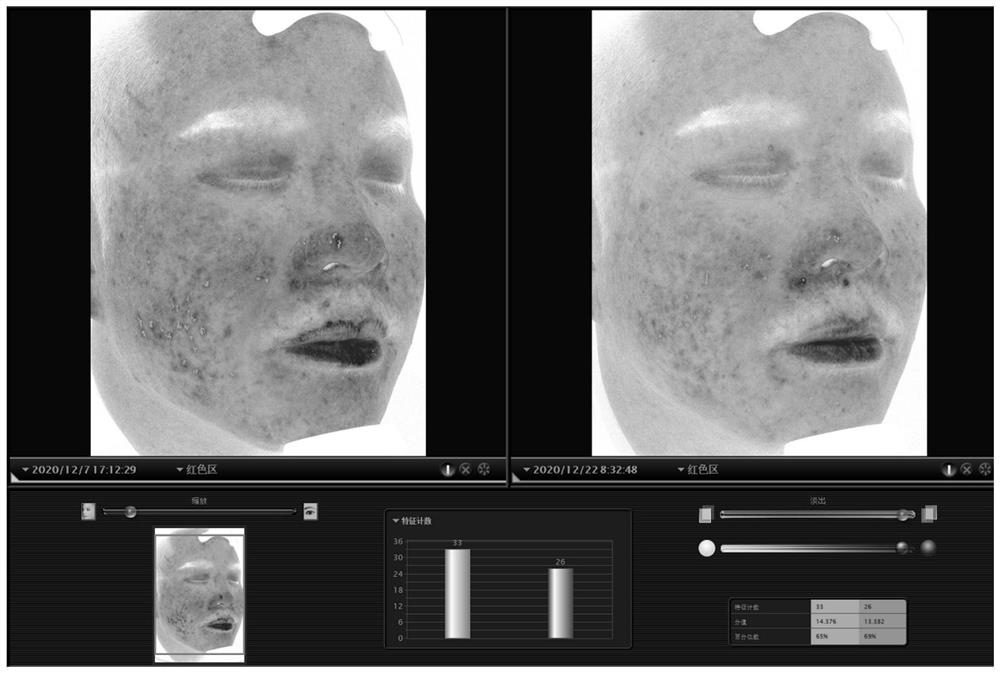

Image

Examples

Embodiment 1

[0033] A preparation method of compound flower extract, comprising the steps of:

[0034] (1) Pick fresh cornflowers and roses, remove the moldy, moth-eaten, and diseased parts, dry them in the shade indoors, and then mix them according to the weight ratio of 1:10; turn on the pulverizer to crush, sieve, and obtain Plant powder with particle size of 50 mesh;

[0035] (2) Add butylated hydroxytoluene in glycerol tri(ethylhexanoate) and heat to dissolve, the content of butylated hydroxytoluene in glycerol tri(ethylhexanoate) is 0.05wt%; mix with plant powder after cooling, The ratio of solid to liquid is 1:10, soak under stirring; then put it into a high-pressure micro-fluidic extractor for extraction, the flow rate is 50L / min, the frequency is 10Hz, and the supernatant is obtained by centrifuging at 3000rpm for 30min;

[0036] (3) The supernatant was aged for 7 days, frozen at 1° C. for 24 hours, and then filtered through a 1000-mesh filter cloth to obtain the compound flower ...

Embodiment 2

[0038] A preparation method of compound flower extract, comprising the steps of:

[0039] (1) Pick fresh cornflowers and roses, remove the moldy, moth-eaten, and diseased parts, dry them in the shade indoors, and then mix them according to the weight ratio of 10:1; turn on the pulverizer to crush, sieve, and obtain Plant powder with particle size of 100 mesh;

[0040] (2) Add butylated hydroxytoluene in glycerol tri(ethylhexanoate) and heat to dissolve, the content of butylated hydroxytoluene in glycerol tri(ethylhexanoate) is 0.01wt%; mix with plant powder after cooling, The material-to-liquid ratio is 1:15, soaked under stirring; then put into a high-pressure micro-fluidic extractor for extraction, the flow rate is 10L / min, the frequency is 50Hz, and the frequency is 50Hz, centrifuged at 3000rpm for 30min to obtain the supernatant;

[0041] (3) The supernatant was left to age for 3 days, frozen at 5°C for 12 hours, and then filtered through a 2000-mesh filter cloth to obtai...

Embodiment 3

[0043] A preparation method of compound flower extract, comprising the steps of:

[0044] (1) Pick fresh cornflowers and roses, remove mildew, insects, and diseased parts, dry them in the shade indoors, and then mix them according to the weight ratio of 7:3; turn on the pulverizer to crush, sieve, and obtain Plant powder with particle size of 80 mesh;

[0045] (2) Add butylated hydroxytoluene in glycerol tri(ethylhexanoate) and heat to dissolve, the content of butylated hydroxytoluene in glycerol tri(ethylhexanoate) is 0.03wt%; after cooling, mix with plant powder, The ratio of solid to liquid is 1:12, soak under stirring; then put it into a high-pressure micro-fluidic extractor for extraction, the flow rate is 30L / min, the frequency is 30Hz, and the supernatant is obtained by centrifuging at 3000rpm for 30min;

[0046] (3) The supernatant was left to age for 5 days, frozen at 3°C for 18 hours, and then filtered through a 1500-mesh filter cloth to obtain the compound flower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com