Recovery method of copper-cobalt ore

A recovery method, copper and cobalt technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the difficulty and cost of smelting operations, the inability to achieve effective separation of copper and cobalt, and the comprehensive recovery of valuable metal iron, etc. problems, to achieve the effect of improving resource utilization, inhibiting sulfide minerals, and improving grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A copper-cobalt ore has a copper grade of 2.02%, a cobalt grade of 0.083%, and an iron grade of 4.96%.

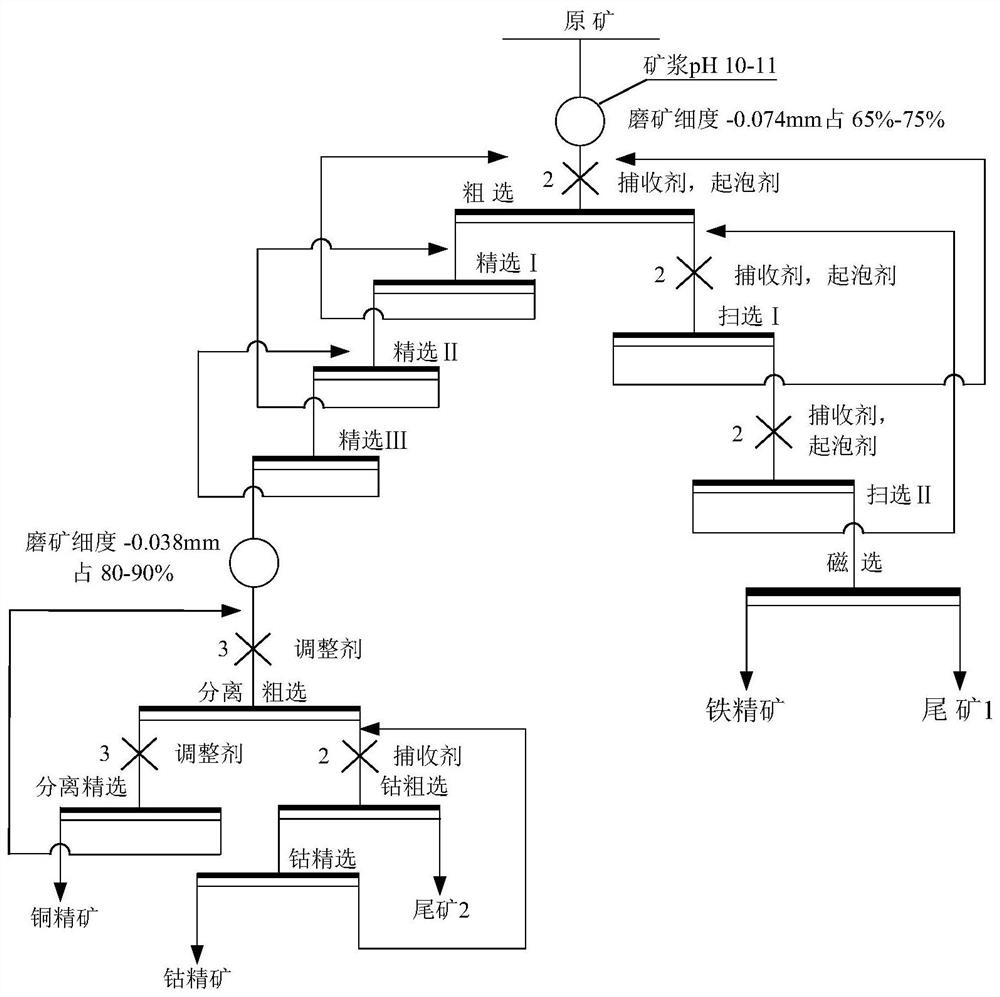

[0044] Such as figure 1 Shown, the recovery method of copper-cobalt ore comprises the steps:

[0045] (1) The copper-cobalt ore raw ore is ground by a ball mill, and the grinding fineness is -0.074mm, which accounts for 60%, and the slurry pH regulator lime is added to the grinding slurry, so that the pH value of the slurry is 11;

[0046] (2) Copper-cobalt ore flotation roughing: Copper-cobalt mixed flotation roughing is carried out on the pulp, and 60g / t is added during the roughing process 原矿 Collector mixture of butyl xanthate and thiazidiene ester, wherein the mass ratio of butyl xanthate and thiazidiene ester is 1:1, add 10g / t 原矿 Foaming agent MIBC, the flotation time is 5min, to obtain copper-cobalt rough concentrate and rougher tailings;

[0047] (3) Sweeping of rougher tailings: carry out two stages of sweeping to the mixed flotation rougher tailings obta...

Embodiment 2

[0056] A copper-cobalt ore has a copper grade of 2.66%, a cobalt grade of 0.11%, and an iron grade of 5.68%.

[0057] Such as figure 1 Shown, the recovery method of copper-cobalt ore comprises the steps:

[0058] (1) The raw ore of copper-cobalt ore is ground by a ball mill, and the grinding fineness is -0.074mm, which accounts for 65%, and the slurry pH regulator lime is added to the grinding slurry, so that the pH value of the slurry is 10;

[0059] (2) Copper-cobalt ore flotation roughing: Copper-cobalt mixed flotation roughing is carried out on the pulp, and 70g / t is added during the roughing process 原矿 The mixture of collector butyl xanthate and thiazidiene ester, wherein the mass ratio of butyl xanthate and thiazidiene ester is 3:7, add 20g / t 原矿 Foaming agent MIBC, the flotation time is 5min, to obtain copper-cobalt rough concentrate and rougher tailings;

[0060] (3) Sweeping of rougher tailings: carry out two stages of sweeping to the mixed flotation rougher tailing...

Embodiment 3

[0069] A copper-cobalt ore has a copper grade of 3.78%, a cobalt grade of 0.156%, and an iron grade of 4.76%.

[0070] Such as figure 1 Shown, the recovery method of copper-cobalt ore comprises the steps:

[0071] (1) The copper-cobalt ore raw ore is ground by a ball mill, and the grinding fineness is -0.074mm, which accounts for 70%, and the slurry pH regulator lime is added to the grinding slurry, so that the pH value of the slurry is 10.5;

[0072] (2) Copper-cobalt ore flotation roughing: Copper-cobalt mixed flotation roughing is carried out on the pulp, and 70g / t is added during the roughing process 原矿 Collector mixture of butyl xanthate and thiazidiene ester, wherein the mass ratio of butyl xanthate and thiazidiene ester is 7:3, add 15g / t 原矿 The frother MIBC, the flotation time is 5min, to obtain copper-cobalt rough concentrate and rougher tailings;

[0073] (3) Sweeping of rougher tailings: carry out two stages of sweeping to the mixed flotation rougher tailings obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com