Novel short-process resourceful treatment process for kitchen garbage

A technology for kitchen waste and processing technology, which is applied in the field of new-type short-process resource treatment technology for kitchen waste, can solve the problems of resource processing and utilization difficulty, changing the physical properties of kitchen waste, and harsh manual sorting environment, etc. Eliminate the effects of manual sorting, compact structure and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

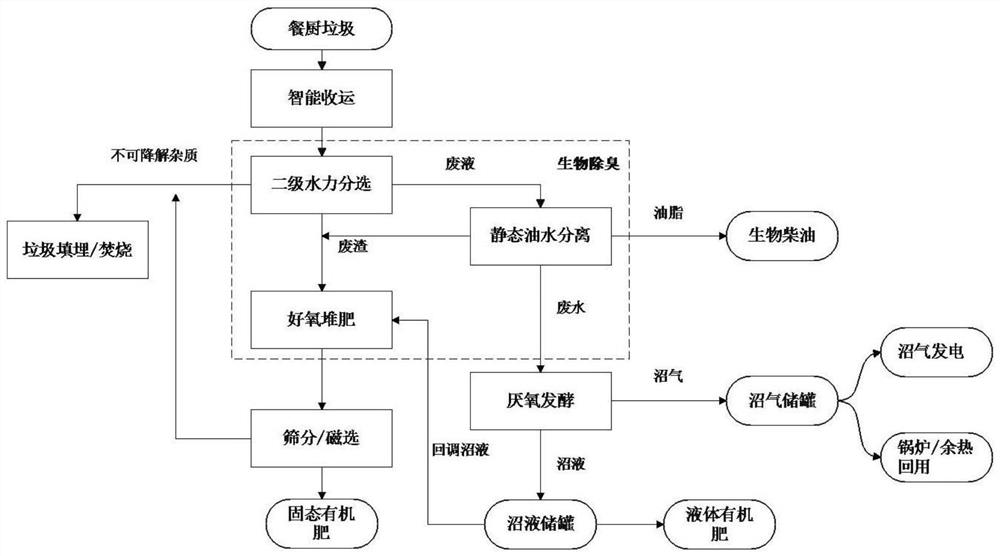

[0052] Embodiment 1 A new type of kitchen waste short-process resource treatment process, the process flow is described as follows:

[0053] 1. After the food waste is transported by the special collection and transportation vehicle to the food waste resource treatment plant, it is first weighed and measured, and then enters the pretreatment workshop and passes through the unloading platform to unload the materials in the collection and transportation vehicle into the high-efficiency pretreatment system The receiving bin; the high-efficiency pretreatment system includes a secondary hydraulic separation process section and a static oil-water separation process section.

[0054] 2. The pretreatment module of the secondary hydraulic separation device removes most of the inorganic substances such as packaging bags, glass, and ceramics mixed in, as well as hard objects such as large bones and fruit shells that are easy to damage subsequent processing equipment, as non-degradable imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com