Modified aerogel nanoparticles and application thereof

An aerogel nano and nano particle technology, applied in the field of nano particles, can solve the problems of rare application of aerogel nano materials, achieve enhanced heat resistance and anti-freeze effect, widen application range, improve oxidation stability and thermal decomposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

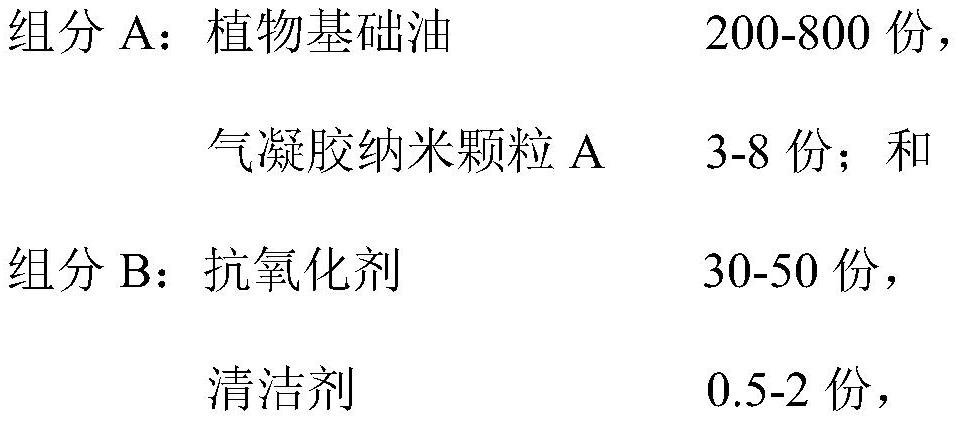

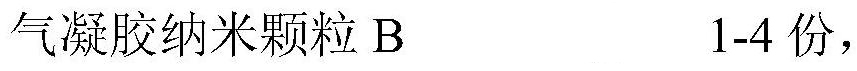

Method used

Image

Examples

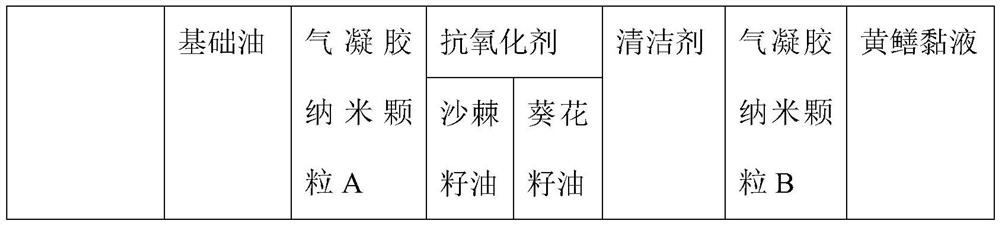

Embodiment 1

[0060] Step 1: the preparation of airgel nanoparticles A: 10 grams of cellulose nanofibers (mass fraction is 1.51%) were mixed with deionized water, ultrasonic treatment was performed for 8 minutes to obtain a nanoparticle dispersion, and nanocellulose and N-( Add N-(2-aminoethyl)-3-aminopropyltrimethoxysilane (KH-792) in a mass ratio of 2-aminoethyl)-3-aminopropyltrimethoxysilane (KH-792), mix , Stir the mixture at a speed of 700r / min for 2 hours at room temperature, freeze in liquid nitrogen for 30 minutes, vacuum freeze-dry for 24 hours, and dry in an oven at 100°C for 30 minutes to obtain KH-792 modified cellulose airgel nanoparticles .

[0061] Step 2: Preparation of Airgel Nanoparticles B: Mix 2 grams of cellulose nanofibers with deionized water, sonicate for 5 minutes to obtain a dispersion, add aqueous ethylenediaminetetraacetic acid, stir at room temperature for 28 hours, and filter with suction. Wash several times with ultrapure water, and dry at 95°C for 30 minutes...

Embodiment 2

[0064] Except that the mass parts of the KH-792 modified cellulose airgel nanoparticles in Example 1 are replaced by 3 mass parts, the mass parts of sulfurized seabuckthorn seed oil with a sulfur content of 3% are replaced by 20 mass parts, and the sulfur content is 3%. Except that the mass parts of sulfurized sunflower oil were replaced by 10 parts by mass and the mass parts of EDTA-modified cellulose airgel nanoparticles were replaced by 1 mass part, the remaining component contents and operating conditions were the same as in Example 1.

Embodiment 3

[0066] In addition to changing the cellulose airgel nanoparticles of 6 mass parts of KH-792 modification in Example 1 into 8 mass parts of 3-aminopropyltrimethoxysilane (KH-540), sulfur content 3% The mass parts of sulfurized seabuckthorn seed oil are replaced by 42 mass parts, the mass parts of sulfurized sunflower oil with a sulfur content of 3% are replaced by 7 mass parts and the mass parts of EDTA-modified cellulose airgel nanoparticles are replaced by 4 mass parts Except, all the other composition content and operating conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com