Foamed ceramic and preparation method and application thereof

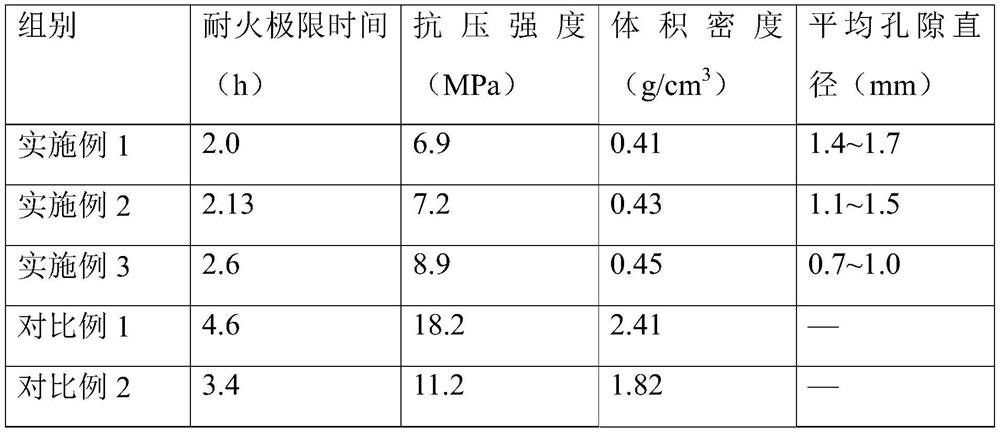

A technology of foaming ceramics and foaming agent, applied in the field of building ceramics, can solve the problem of inability to use floor firewalls or load-bearing walls, and achieve the effects of increasing the fire resistance limit, increasing the thickness of the hole wall, and improving the strength of the matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Some embodiments of the present invention also provide the preparation method of the above-mentioned foamed ceramics, which includes: firing according to the ratio of raw materials to obtain foamed ceramics. The foamed ceramics fired through the above raw material ratios have good mechanical strength and fire resistance, and the preparation method is simple to operate, energy-saving and environment-friendly.

[0026] In order to ensure the firing effect of the foamed ceramics, in some embodiments, the raw material mixture needs to be granulated first, and then the granulated raw material particles are placed in a mold for firing. By means of granulation, the agglomeration of raw materials can be avoided, which will affect the performance of the final fired foamed ceramics.

[0027] Furthermore, in order to make the foamed ceramics formed in the mold have a good structure, there are certain requirements on the particle size of the granulation. Generally, the particle siz...

Embodiment 1

[0044] This embodiment provides a preparation method for prolonging the refractory limit time of foamed ceramics, comprising the following steps:

[0045] (1) Preparation of foamed ceramic main ingredient formula, said formula comprises 66 parts of Xinhua Tao polishing slag, 12 parts of Fuzhou potash sodium sand, 8 parts of Jinyi Tao foamed ceramic fine powder, 6 parts of bentonite, 3 parts of talc particles and 5 Granite Stone Dust.

[0046] (2) Weigh the main ingredient formulation and the modified soil according to the mass ratio of the main ingredient formulation of the foamed ceramics to the modified soil being 90:10.

[0047] (3) Weigh the composite foaming agent according to 0.65% of the total weight of the foamed ceramic formulation and the modified soil, wherein the mass ratio of silicon carbide and manganese oxide is 8:5.

[0048] (4) Pour the weighed foam ceramic main ingredient formula, modified soil and composite foaming agent powder into a ball mill jar, and bal...

Embodiment 2

[0054] This embodiment provides a preparation method for prolonging the refractory limit time of foamed ceramics, comprising the following steps:

[0055] (1) Weighing the foamed ceramic main ingredient formula, said main ingredient formula comprises 67 parts of polishing slag, 14 parts of Fuzhou potassium sodium sand, 6 parts of Jinyi Tao foamed ceramic fine powder, 6 parts of bentonite, 2 parts of talcum grains and 5 Granite Stone Dust.

[0056] (2) Weigh the main ingredient formulation and the modified soil according to the mass ratio of the main ingredient formulation of the foamed ceramics to the modified soil being 85:15.

[0057] (3) Weigh the composite foaming agent according to 0.75% of the total weight of the main ingredient of the foamed ceramics and the modified soil, wherein the mass ratio of silicon carbide and manganese oxide is 8:5.

[0058] (4) Pour the weighed foam ceramic main ingredient formula, modified soil and composite foaming agent powder into a ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com