Reaction kettle inner wall nano coating and preparation method thereof

A nano-coating and reactor technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as coatings are easy to absorb water, easy to mold, and reaction materials are easy to stick, and the preparation method is simple and easy , Reduce friction coefficient, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

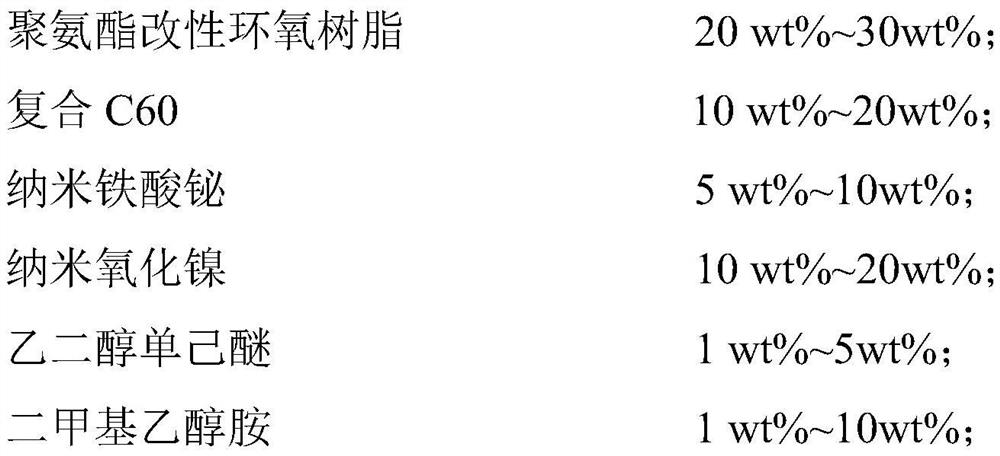

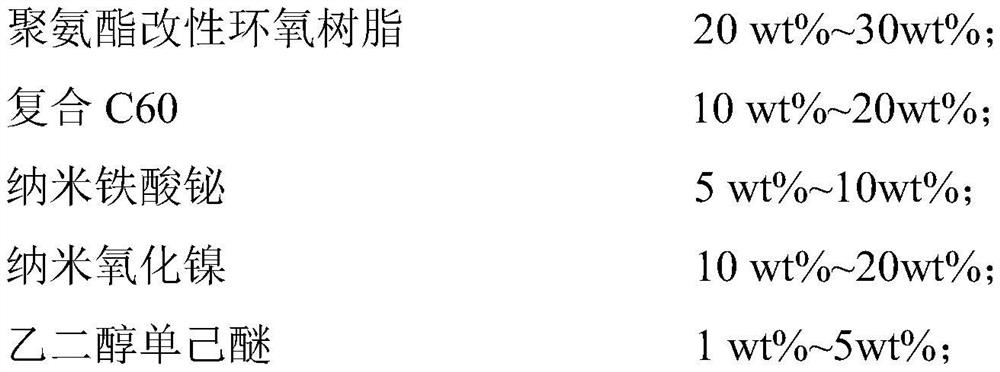

[0050] The preparation method of described a kind of reaction kettle inner wall nano-coating, comprises the following steps:

[0051] (1) Provide the following components in proportion: polyurethane modified epoxy resin, composite C60, nano-bismuth ferrite, nano-nickel oxide, ethylene glycol monohexyl ether, dimethylethanolamine and solvent.

[0052] (2) Add the composite C60 and bismuth ferrite into the polyurethane modified epoxy resin, and stir for 60-120min at a temperature of 30-60°C until the mixture is uniform, and a mixed liquid A is obtained;

[0053] (3) adding nano-nickel oxide into the solvent under stirring, and stirring at a temperature of 50-60° C. for 30-60 minutes, and then continuing to stir for 30-60 minutes to obtain a mixed solution B;

[0054] (4) Slowly add the mixed solution B into the mixed solution A, and stir at 30-50°C until the mixed solution is evenly mixed to prepare the mixed solution C;

Embodiment 1

[0060] The components and mass fractions of the nano-coating on the inner wall of the reactor are as follows: 20wt% polyurethane modified epoxy resin, 10wt% composite C6010wt%, 5wt% bismuth ferrite, 20wt% nickel oxide, ethylene glycol mono 5wt% hexyl ether, 10wt% dimethylethanolamine and 30wt% solvent.

[0061] (1) Provide the following components in proportion: polyurethane modified epoxy resin, composite C60, nano-bismuth ferrite, nano-nickel oxide, ethylene glycol monohexyl ether, dimethylethanolamine and solvent.

[0062] (2) Add the composite C60 and bismuth ferrite into the polyurethane modified epoxy resin, and stir for 60 minutes at a temperature of 60°C until the mixture is evenly mixed to obtain a mixed solution A;

[0063] (3) adding nano-nickel oxide into the solvent under stirring, and stirring at a temperature of 50-60°C for 30-60 minutes, and then continuing to stir for 60 minutes to obtain a mixed solution B;

[0064] (4) Slowly add the mixed solution B to the...

Embodiment 2

[0067] In a more specific embodiment, the components of the nano-coating on the inner wall of the reactor and the mass fractions of the components are as follows: 25wt% polyurethane modified epoxy resin, 15wt% composite C60, 10wt% bismuth ferrite, nickel oxide 10 wt%, ethylene glycol monohexyl ether 5 wt%, dimethylethanolamine 5 wt%, and 30 wt% solvent.

[0068] (1) Provide the following components in proportion: polyurethane modified epoxy resin, composite C60, nano-bismuth ferrite, nano-nickel oxide, ethylene glycol monohexyl ether, dimethylethanolamine and solvent.

[0069] (2) Add composite C60 and bismuth ferrite into polyurethane modified epoxy resin, and stir at 60°C for 80 minutes until uniformly mixed to obtain mixed liquid A;

[0070] (3) adding nano-nickel oxide into the solvent under stirring, and stirring for 45 minutes at a temperature of 55° C., and then continuing to stir for 30 to 60 minutes to obtain a mixed solution B;

[0071] (4) Slowly add the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com