Patents

Literature

30 results about "Ethylene glycol monohexyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive heating coating

The invention discloses a conductive heating coating which comprises the following components in parts by weight: 24-36 parts of lithium silicate, 20-30 parts of graphite nodules, 16-18 parts of vanadium trioxide, 10-20 parts of azo-dicarbonamide, 8-12 parts of zinc oxide, 4-12 parts of benzoyl peroxide, 12-18 parts of dibutyl phthalate, 10-20 parts of triphenyl phosphate, 4-8 parts of isopropyl acrylate, 12-16 parts of epoxy resin, 8-12 parts of butyl acetate, 4-12 parts of ethylene glycol, 2-8 parts of ethylene glycol monohexyl ether, 4-8 parts of dimethyl ethanolamine, and 4-6 parts of zirconate calcium carbonate. The conductive heating coating provided by the invention is simple in manufacturing; the adopted production raw materials are non-toxic, therefore, the coating is good in application effect, and environment-friendly; and a conductive paint film formed by the coating has good electric conductivity.

Owner:姜云华

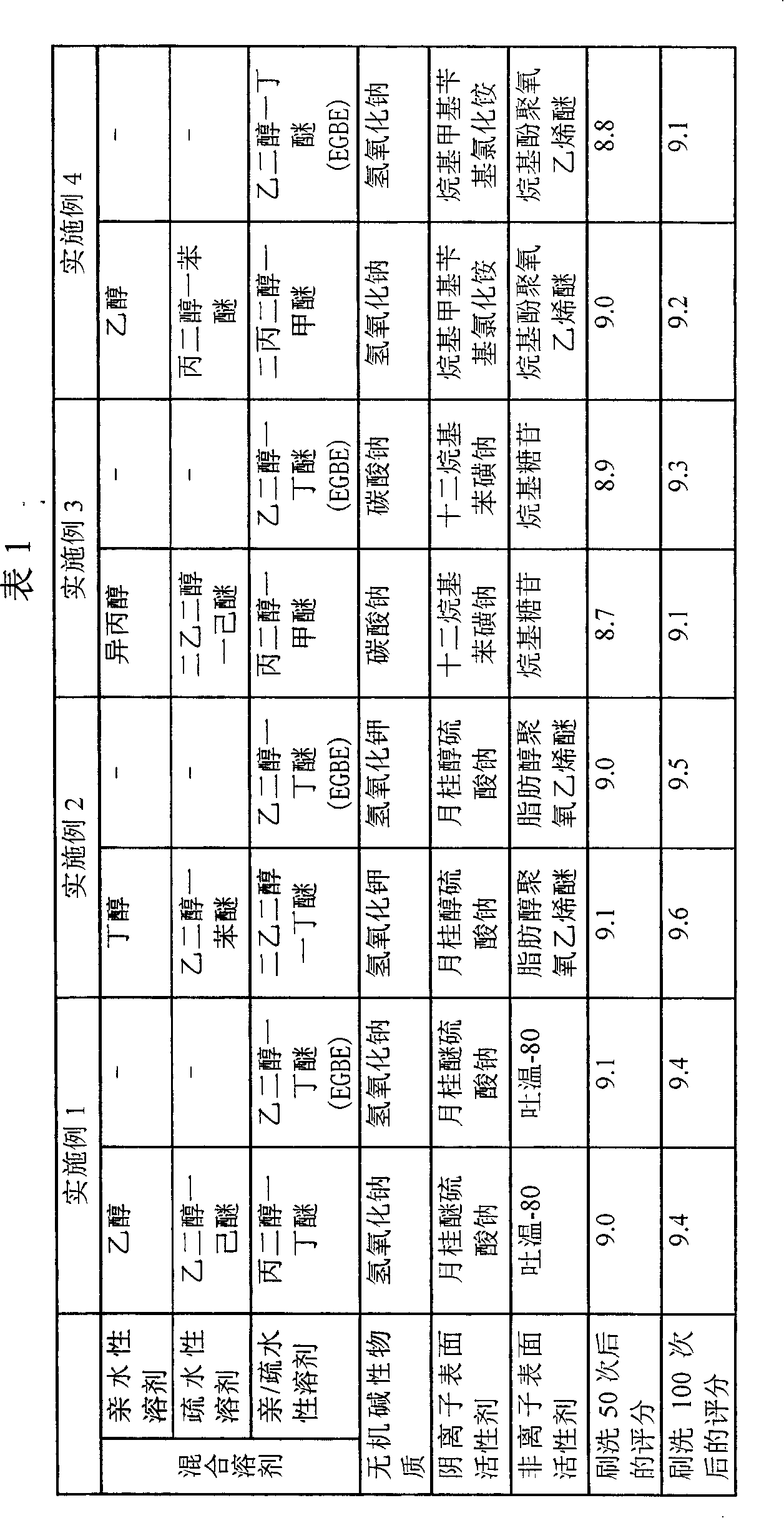

Kitchen detergent composition

InactiveCN101210213ANo toxicityEasy to cleanNon-ionic surface-active compoundsDetergent compounding agentsDiethylene glycol monobutyl etherEthylene glycol monophenyl ether

The invention relates to an alkaline kitchen cleanser composition with no ethylene glycol monobutyl ether (EGBE) for cleaning hard surface with heavy oil stains, and also relates to a mixture solvent capable of substituting for the EGBE solvent in the cleanser composition. The alkaline kitchen cleanser composition mainly comprises (a) a mixed solvent of a hydrophilic solvent and a hydrophobic solvent; (b) an inorganic alkaline substance; and (c) a surfactant. The mixed solvent includes the hydrophobic solvent selected from ethylene glycol monophenyl ether, ethylene glycol monohexyl ether and combination thereof, a hydrophilic diethylene glycol monobutyl ether solvent and a hydrophilic isopropyl alcohol solvent. The alkaline kitchen cleanser composition contains no EGBE, thus eliminating the latent toxicity. Meanwhile, the composition is at low cost and can be mixed to obtain better or more diversified smells.

Owner:SC JOHNSON & SON INC

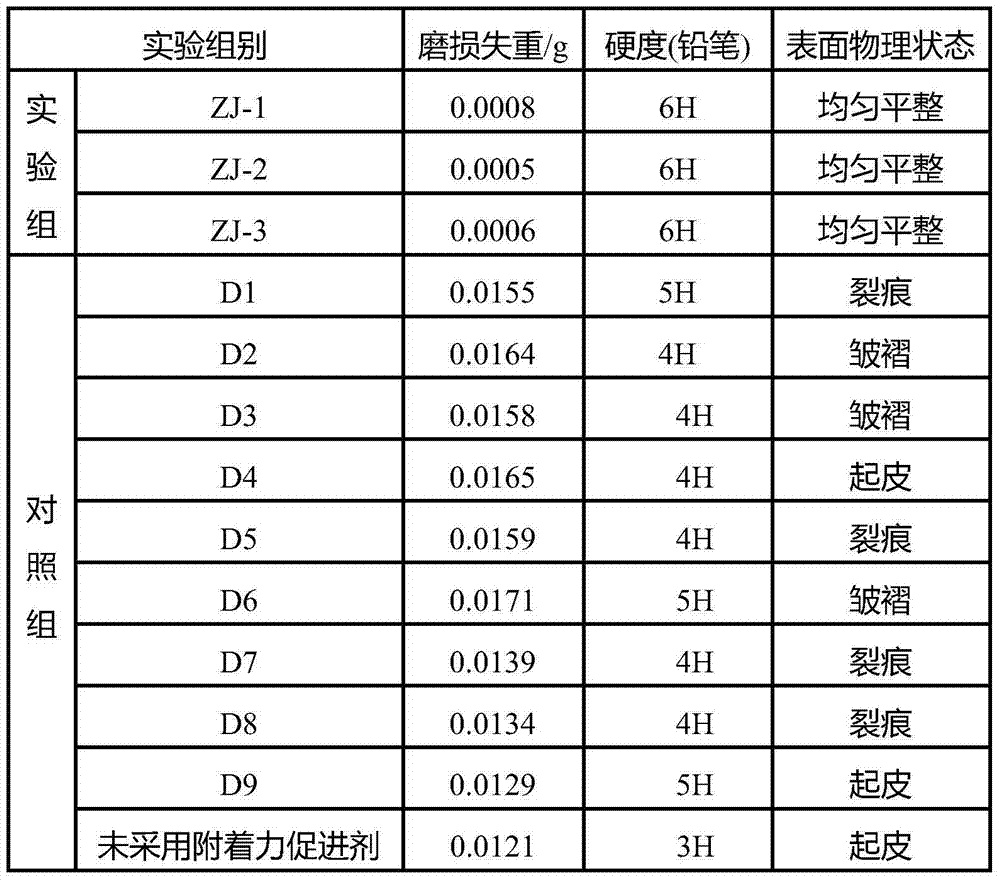

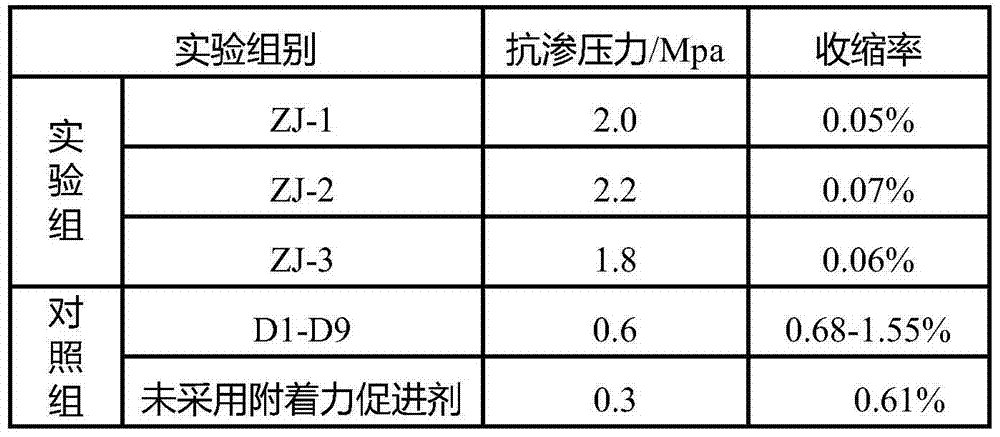

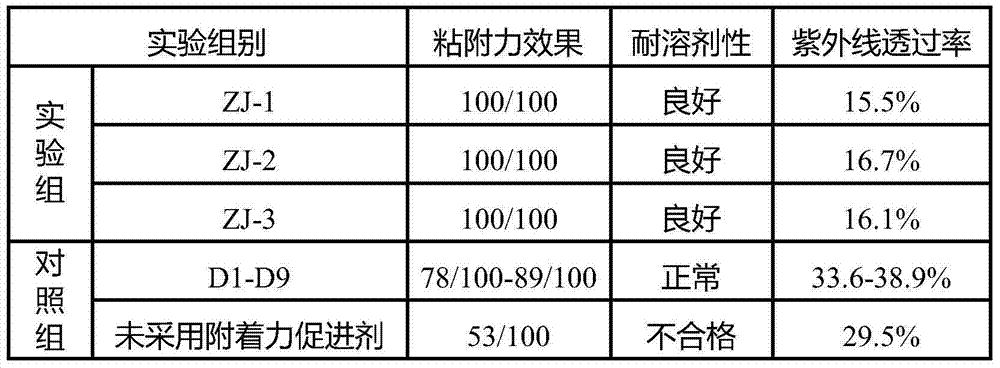

Environment-friendly spraying method for construction

ActiveCN103480557AEasy to follow upImprove wear resistancePretreated surfacesSpecial surfacesEnvironmental resistanceWear resistant

The invention relates to an environment-friendly spraying method for construction by use of coating additives. The coating additives comprise hydroxypropyl methyl cellulose, modified sulfur powder, nanometer zirconium phosphate composite material, electrical nanometer polycrystalline diamond powder, attapulgite, an additive, ethylene glycol monohexyl ether, glycerol and deionized water; the spraying method has unexpected synergism by combination of the coating additives and proper optimization of technological parameters, the prepared coating has excellent wear-resistant, anti-cracking, ultraviolet-prevention and waterproof effects, can be widely applied to spraying of surfaces such as steel sheets for decoration, wood surface, furnish surface and wallpaper surface, fully meets the requirement of persons for diversified functions and has good industrial application prospect and market value.

Owner:BEIJING SHENGHAO UNIVERSE TECH DEV

Binder used for preparing clay-like brazing filler

InactiveCN1757692AImprove plasticityIncrease the use of functionsEster polymer adhesivesWelding/cutting media/materialsCross-linkAdhesive

An adhesive for preparing clay-state solder is prepared from the 10-30 alkylacrylate cross-linked copolymer, glycerin, and solvent chosen from deionized water, diethanediol mono-butylether, diethanediol mono-hexylether, 1,2-propanediol and 2,4-hexanediol. It can be used to generate the artistic pattern on the surface of metal by vacuum soldering.

Owner:李昕

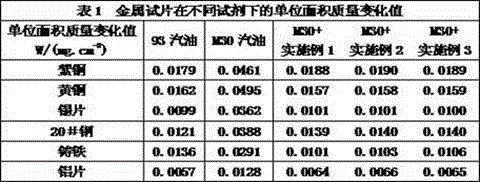

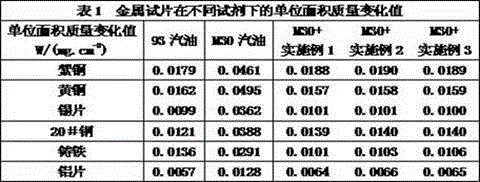

M30 methanol gasoline corrosion inhibitor

ActiveCN104449895AImprove performanceEasy to useLiquid carbonaceous fuelsFuel additivesOctanolDiethyl ether

The invention relates to an M30 methanol gasoline corrosion inhibitor which is prepared from the following components in parts by weight: 8 parts of petroleum ether, 12 parts of 2-chloro-4-nitryl imidazole, 16 parts of ethylene glycol monoethyl ether, 12 parts of trimethylolpropane mono allyl ether, 6 parts of creatine hexaphosphate, 8 parts of heptamethyldisilazane, 12 parts of diethoxyethylamine, 7 parts of zinc dialkyl dithiophosphate, 9 parts of dibenzofuran, 12 parts of octanol and 10 parts of glycol ether. The M30 methanol gasoline corrosion inhibitor provided by the invention is prepared from the following components such as a power promoter, a metal anti-wear reagent at extreme pressure, a rubber swelling inhibitor, a corrosion inhibitor and the like. The M30 methanol gasoline corrosion inhibitor has excellent antioxidant ability and corrosion resistant performance and effectively prevents automobile metals from being corroded in the using process, particularly corrosion on a cast iron generator.

Owner:南通三泰九圆钢结构有限公司

Novel hot-melting welding material

InactiveCN104923982APerformance is not affectedPerformance impactWelding/cutting media/materialsAlumino-thermic welding apparatusDiethylene glycol monohexyl etherPhosphoric acid

A novel hot-melting welding material is prepared by the following raw materials: 11-17 parts by weight of cuprous oxide, 4-8 parts by weight of emulgator, 0.5-2 parts by weight of OP-10, 3-5 parts by weight of nano-silver, 7-10 parts by weight of benzimidazole, 1.2-5 parts by weight of diethylene glycol monohexyl ether, 4-7 parts by weight of malonic acid, 4-9 parts by weight of stearic acid, 3-7 parts by weight of rutile, 1.2-2 parts by weight of diammonium phosphate, 4-10 parts by weight of vanadium-nitrogen alloy, 8-10 parts by weight of EVA resin, 2-5 parts by weight of octanol, 2-4 parts by weight of ethylamine hydrochloride, 8-13 parts by weight of fatty alcohol-polyoxyethylene ether, 5-10 parts by weight of ferrotitanium and 6-10 parts by weight of nitroethane. The novel hot-melting welding material has the advantages that the novel hot-melting welding material enables the welding effect to be improved, is more smooth and firm and meanwhile has no influence on the performance of welding parts.

Owner:QINGDAO KELIKE INFORMATION TECH

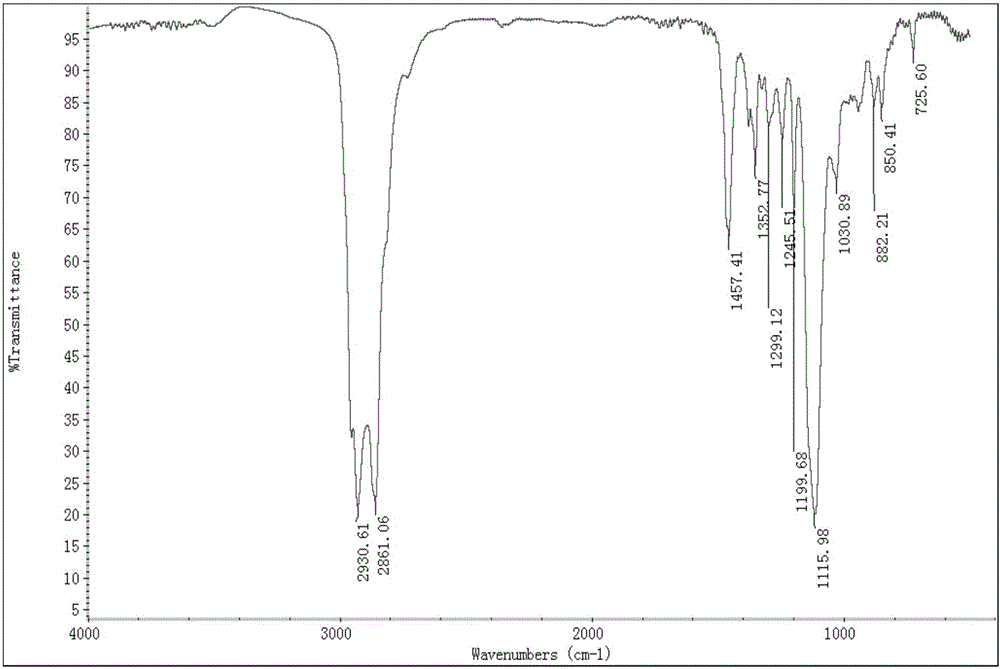

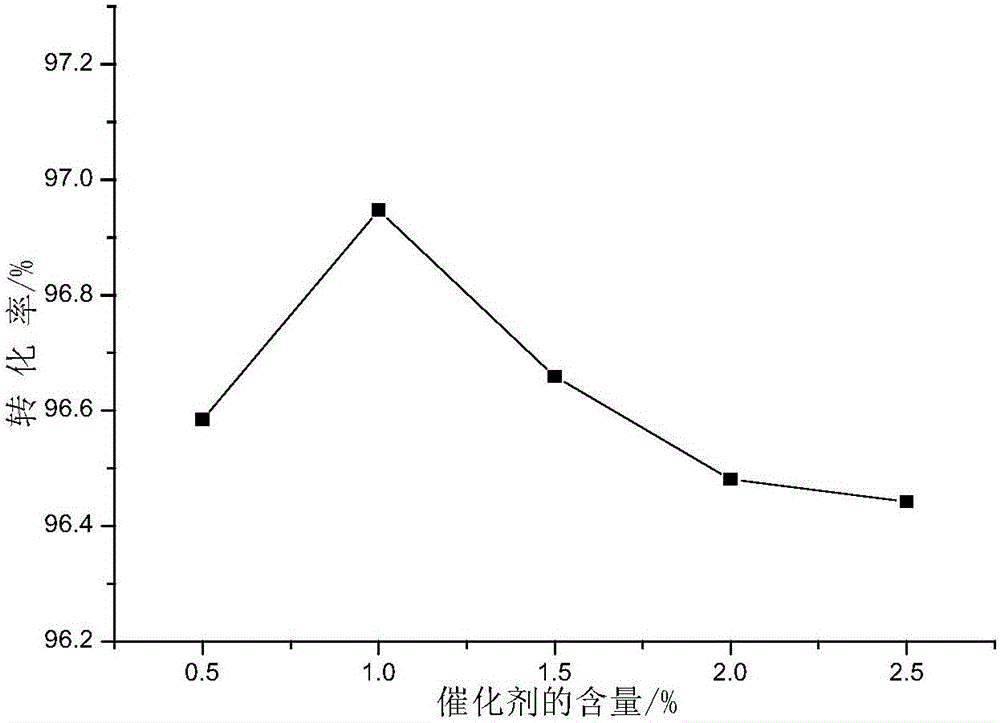

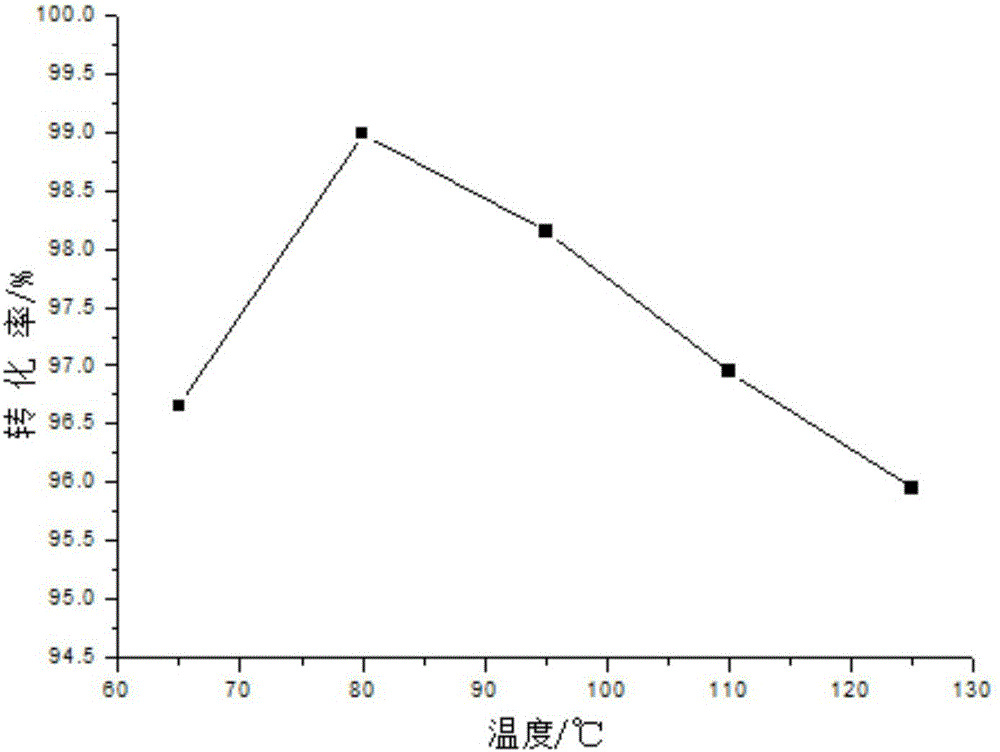

Method for synthesizing diethylene glycol methyl hexyl ether

InactiveCN106631711ALow toxicitySmooth responseOrganic compound preparationAlkali metal chloridesDiethylene glycol monohexyl etherFiltration

The invention discloses a method for synthesizing diethylene glycol methyl hexyl ether. The method comprises the following steps: (1) putting a raw material, namely sodium hydroxide, into a reaction kettle, adding a diluted hydrochloric acid solution into the reaction kettle slowly and dropwise and reacting to produce sodium chloride; (2) adding diethylene glycol monohexyl ether into the reaction kettle in the step (1) dropwise, and introducing the obtained sodium alcoholate intermediate product into the next level of reaction kettle; (3) coating the secondary reaction kettle, in which the sodium alceholate intermediate product is put, with a graphite layer, introducing methyl iodide into the secondary reaction kettle and reacting to obtain a final product, namely the diethylene glycol methyl hexyl ether; (4) after the reaction in the step (3), cooling to room temperature, standing and layering, and performing pressure-reducing filtration on the upper layer liquid to obtain the final product, namely the diethylene glycol methyl hexyl ether. The method has the advantages that the diethylene glycol methyl hexyl ether is synthesized by innovatively adopting the new raw material; the whole synthesis method is stable in reaction and easy to operate; the obtained final product has high yield and high purity; the method is suitable for industrialized production and breaks through bottleneck for commercial popularization of the products.

Owner:HUANGSHAN UNIV

Special soldering tin paste used for welding multi-stage package patch element

ActiveCN110653516AReduce manufacturing costEasy to implementWelding/cutting media/materialsSoldering mediaButanedioic acidDiethylene glycol monohexyl ether

The invention belongs to special soldering tin paste used for welding a multi-stage package patch element and particularly applicable to the occasion with the service temperature higher than 240 DEG Cafter welding. The special soldering tin paste comprises a tin alloy, nanometer metal, a rare earth alloy and soldering aid paste. Tin alloy powder is a mixture of one or two of tin silver alloy powder, tin antimony alloy powder, tin copper alloy powder and tin lead alloy powder. Nanometer metal powder is a mixture of one or two of copper powder, lead powder, titanium powder, cobalt powder and gold powder. Effective components of the soldering aid paste comprise hydrogenated rosin, diethylene glycol monohexyl ether, succinic acid, methyl-1H-benzotriazole and citric acid. A manufacturing method of the paste comprises a few steps of preparing the tin alloy powder, the nanometer metal powder, the rare earth alloy powder and the weld aid paste and mixing. By the adoption of the technical scheme, elementary-substance metal particles or alloy particles are added into the tin paste, corresponding nanometer auxiliary additives are added, thus the preparation cost is lower than that of nanometer soldering paste, and the special soldering tin paste is easy to achieve and wide in application range.

Owner:深圳群崴半导体材料有限公司

Environment-friendly tin paste special for lead-free low-temperature through hole

InactiveCN106736005ASolve the drop phenomenonGuaranteed stabilityWelding/cutting media/materialsSoldering mediaHalogenActive agent

The invention relates to environment-friendly tin paste special for a lead-free low-temperature through hole. The environment-friendly tin paste is composed of Sn42Bi58 alloy tin powder and flux paste. The flux paste includes, by mass, 1%-6% of a thixotropic agent 6650, 35%-58% of resin KE-604, 2%-3% of a phenolic antioxidant, 1%-2% of a nonionic halogen compound, 35%-55% of ethylene glycol monohexyl ether and 1.5%-7% of an active agent. The weight ratio of the Sn42Bi58 alloy tin powder to the flux paste is 89:11. According to the environment-friendly tin paste, the phenomenon that the tin paste falls off during element inserting in the THT process is effectively solved, and the stability of the paste is kept; few postwelding residues are generated, transparency performance and insulation performance are good, cleaning is avoided, and extremely high postwelding reliability is achieved; and the unit size of the postwelding tin paste is quite stable, and the phenomenon of much tin or little tin cannot happen.

Owner:东莞市合点电子材料有限公司

Special liquid crystal display screen cleaning agent

InactiveCN107354016AEasy to cleanEffective dissolutionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEpoxyPhenyl Ethers

The invention discloses a special liquid crystal display screen cleaning agent, which comprises the following raw materials by weight: fatty alcohol polyoxyethylene ether, diethylene glycol monohexyl ether, polyoxyethylene alkyl phenyl ether, tripropylene glycol methyl ether, ethylene glycol monoethyl ether, polyoxyethylene sorbitan monooleate, coconut fatty acid diethanolamide, alkyl polyglucoside, nanometer titanium dioxide, an Enteromorpha extract, 5-chloro-2-methylisothiazolinone, N-methyl-2-pyrrolidine, sodium hydrogen ferric DTPA, and dicarboxymethyl alanine trisodium. Compared to the cleaning agent in the prior art, the cleaning agent of the present invention contains the small-molecule acids extracted from the marine plants, can effectively dissolve dust, bug dead bodies, residual glues and other dirt adhered on the liquid crystal display screen surface, can effectively clean the impurities on the surface of light-emitting diode epoxy resin materials, does not corrode liquid crystal display screens and substrates, and further has advantages of safety to environment, environmental protection, no toxicity, and no harm.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

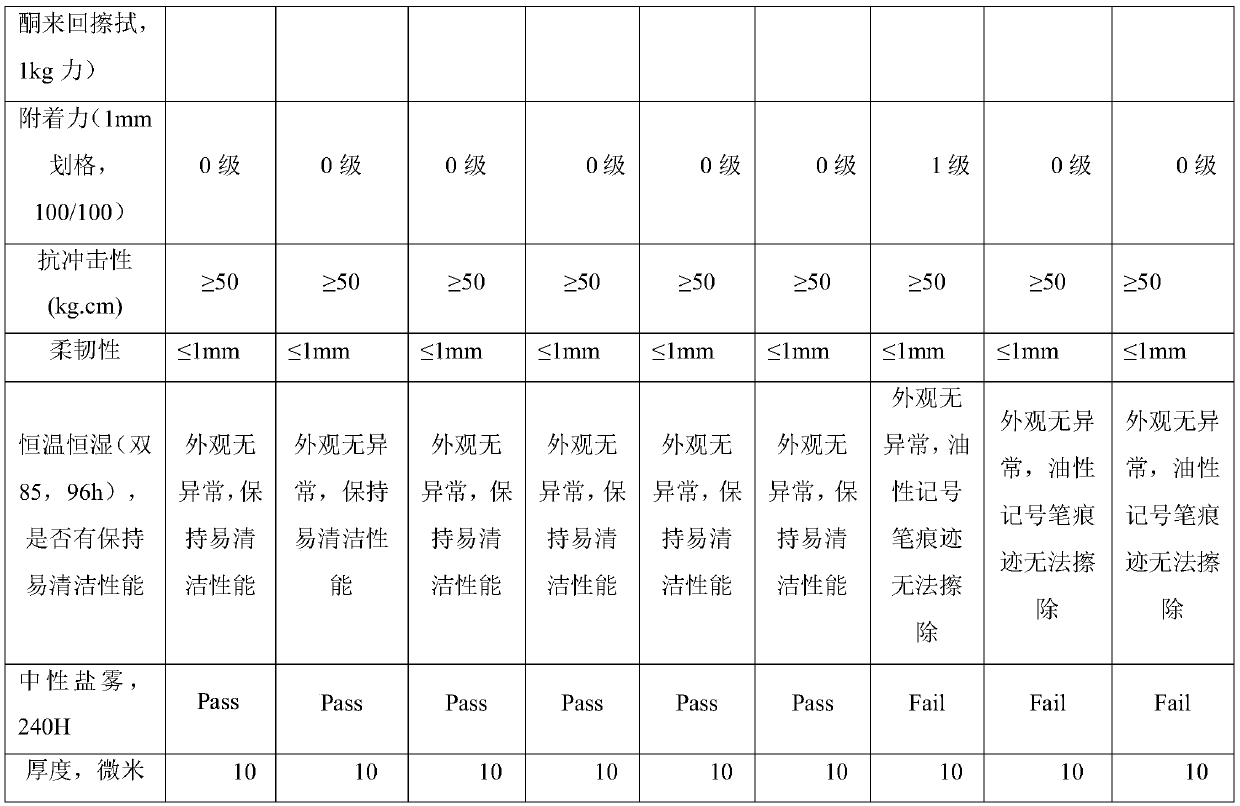

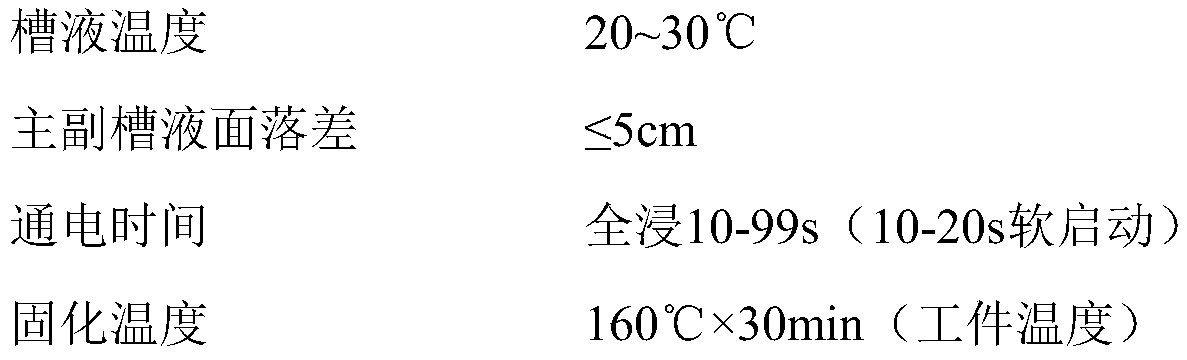

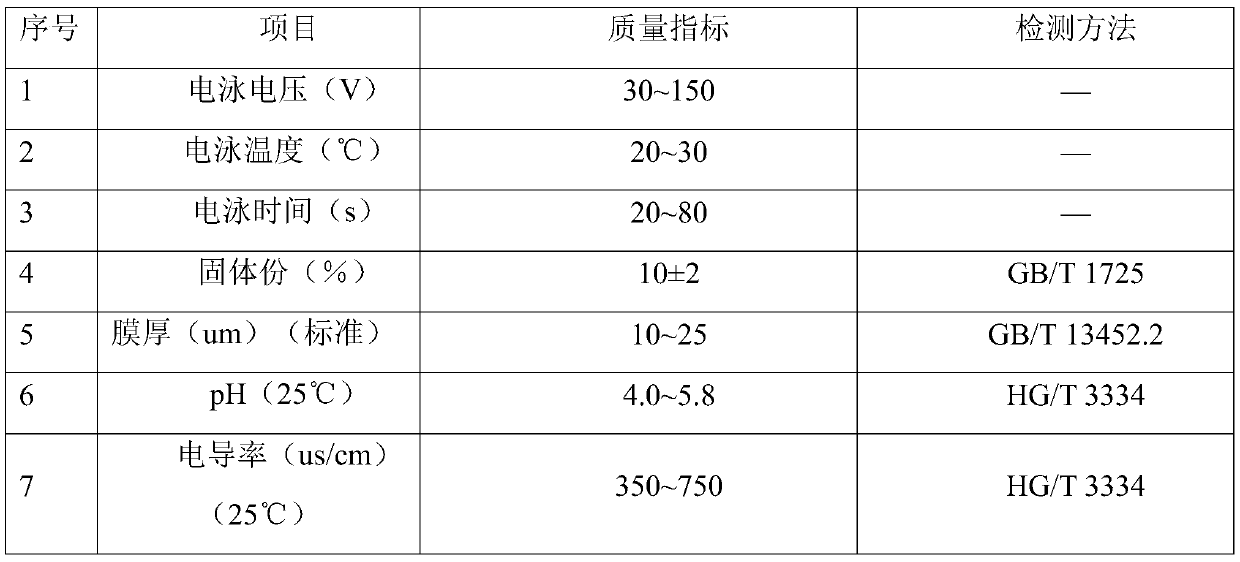

High-performance resin for electrophoretic paint and synthesis method of resin

ActiveCN109970928AImprove hydrophobicity and oleophobicityImprove long-term effectAnti-corrosive paintsPaints for electrolytic applications(Hydroxyethyl)methacrylateSynthesis methods

The invention discloses a high-performance resin for electrophoretic paint and a synthesis method of the resin, and is aimed at providing the high-hardness and high-wear-resistance resin with lastinghydrophoby and lipophobicity for the electrophoretic paint. The resin is technically characterized by being mainly prepared from, by weight, 673-713 parts of butyl acrylate, 590-620 parts of siliconeoil, 139-145 parts of ethylene glycol monohexyl ether, 45-50 parts of tert-butylperoxy-2-ethylhecanoat, 940-980 parts of methyl methacrylate, 78-84 parts of hexafluorobutyl methacrylate, 1000-1060 parts of hydroxyethyl methylacrylate, 470-490 parts of ethyl methacrylate, 540-565 parts of butyl cellosolve, 95-105 parts of hexyl cellosolve, 175-186 parts of an acrylic acid self-crosslinking monomeracetylated and modified by acetyl and 795-1135 parts of isopropanol. The invention belongs to the technical field of resin.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

Novel acrylic acid electrophoretic paint and preparation method thereof

InactiveCN104946060AAnti-corrosive paintsPaints for electrolytic applicationsAcetic acidGlycol ethers

The invention relates to novel acrylic acid electrophoretic paint and a preparation method thereof, wherein the paint comprises a component A, a component B and a component C, wherein the mass ratio of the component A to the component B to the component C is (80-120):(30-50):(5-15); the component A comprises 100-150 parts by mass of acrylic monomer, 30-60 parts by mass of a solvent S1 and 1-10 parts by mass of an initiator; the component B comprises 100-150 parts by mass of an HDI trimer, 53-80 parts by mass of 3,5-dimethylpyrazole, 50-75 parts by mass of a solvent S2 and 0.5-2 parts by mass of a catalyst; the component C, the solvent S1 and the solvent S2 are selected from one or more of acetic acid, isopropyl alcohol, glycol ether and ethylene glycol monohexyl ether. Compared with the conventional acrylic acid electrophoretic paint, the novel acrylic acid electrophoretic paint provided by the invention is greatly improved in salt spray resistance test time while maintaining the aesthetic property.

Owner:深圳市粤辉煌自动化设备有限公司

Fireproof coating

The invention discloses one aspect, a fireproof coating, comprising the following components in parts by weight: 10-20 parts of azodicarbonamide, 10-20 parts of magnesium silicate, 12-18 parts of acetone, 4 parts of ethylene glycol monohexyl ether ~12 parts, 4~6 parts of dimethylethanolamine, 12~16 parts of cobalt calcium carbonate, 2~8 parts of polyisobutyl ester, 4~8 parts of aluminum hydroxide, 10~18 parts of benzoyl peroxide, 8-12 parts of isopropyl acrylate, 4-8 parts of phosphate triester, 10-15 parts of titanium dioxide, 16-18 parts of trimethoxysilane. The invention provides a kind of fireproof paint, various components cooperate with each other, the paint is less toxic, and the coating effect is good, the use time is long, the heat insulation effect of the coating is good, and it can be used in factories and buildings for fire prevention. Applied on the surface of the article can effectively play the role of fire and heat insulation.

Owner:顾裕忠

Chemical reaction kettle inner wall coating

InactiveCN107474741ALow toxicityGood application effectAntifouling/underwater paintsPaints with biocidesChemical reactionPentaerythritol

The invention discloses one aspect, a chemical reaction kettle inner wall coating, comprising the following components in parts by weight: 12-24 parts of norfloxacin, 6-12 parts of dihydroterpineol acetate, 6-12 parts of dihydroterpineol 4-12 parts of ethylene glycol monohexyl ether, 6-10 parts of dimethylethanolamine, 4-8 parts of cobalt sulfate calcium carbonate, 2-4 parts of polyisobutyl ester, 10-22 parts of pentaerythritol, 3-6 parts of resin share. The coating for the inner wall of a chemical reaction kettle provided by the invention has various components that cooperate with each other, the coating has low toxicity, and the coating effect is good, and the use time is long. The inner wall of the kettle can prevent corrosion and high temperature.

Owner:黄琴

m30 methanol gasoline corrosion inhibitor

ActiveCN104449895BImprove performanceEasy to useLiquid carbonaceous fuelsFuel additivesOctanolDiethyl ether

The invention relates to an M30 methanol gasoline corrosion inhibitor which is prepared from the following components in parts by weight: 8 parts of petroleum ether, 12 parts of 2-chloro-4-nitryl imidazole, 16 parts of ethylene glycol monoethyl ether, 12 parts of trimethylolpropane mono allyl ether, 6 parts of creatine hexaphosphate, 8 parts of heptamethyldisilazane, 12 parts of diethoxyethylamine, 7 parts of zinc dialkyl dithiophosphate, 9 parts of dibenzofuran, 12 parts of octanol and 10 parts of glycol ether. The M30 methanol gasoline corrosion inhibitor provided by the invention is prepared from the following components such as a power promoter, a metal anti-wear reagent at extreme pressure, a rubber swelling inhibitor, a corrosion inhibitor and the like. The M30 methanol gasoline corrosion inhibitor has excellent antioxidant ability and corrosion resistant performance and effectively prevents automobile metals from being corroded in the using process, particularly corrosion on a cast iron generator.

Owner:南通三泰九圆钢结构有限公司

Synthetic method for broad-spectrum bactericide peroxyacetic acid

InactiveCN108239011AAvoid corrosionCorrosiveOrganic compound preparationPeroxy compound preparationReaction temperatureSodium sulfate

The invention discloses a synthetic method for the broad-spectrum bactericide peroxyacetic acid. The synthetic method comprises the following steps: adding acetaldehyde and a sodium sulfate solution into a reaction vessel, controlling the temperature of the obtained solution to be 30-37 DEG C, controlling a stirring speed to be 270-290 rpm, adding bromosuccinimide, adding an ethylene glycol monohexyl ether solution in batches within 30-50 min, and continuing a reaction for 80-110 min; and then adding zinc chromate powder, raising reaction temperature to 40-46 DEG C, continuing the reaction for120-180 min, lowering the temperature to 10-15 DEG C, stopping stirring, adding a potassium bromide solution, subjecting the solution to layering, carrying out washing with a cyclopentane solution for 30-60 min, then carrying out recrystallization in a hexanediol solution, and carrying out dehydration with a dehydrating agent so as to obtain the finished peroxyacetic acid.

Owner:CHENGDU WEI ER BO DUN TECH CO LTD

High temperature resistant paint

InactiveCN107353726ALow toxicityGood application effectFireproof paintsAntifouling/underwater paints3-methylbutyric acidPolyetherimide

The invention discloses one aspect, a high temperature resistant coating, comprising the following components in parts by weight: 20-30 parts of methyl 2-hydroxy-3-methyl butyrate, 12-16 parts of polyvinyl alcohol, polyamideimide 8-12 parts of amine, 6-8 parts of polyetherimide, 4-8 parts of polyimide, 7-15 parts of dibutyl ester, 6-12 parts of pentaerythritol, 12-24 parts of norfloxacin, dihydroacetate 6-12 parts of pine oil ester, 6-12 parts of dihydroterpineol, 4-12 parts of ethylene glycol monohexyl ether, 6-10 parts of dimethylethanolamine, 14-18 parts of cobalt calcium carbonate. The invention provides a kind of high temperature resistant coating, various components cooperate with each other, the coating has low toxicity, and the coating effect is good, and the service time is long. , can play the role of anti-corrosion and high temperature resistance.

Owner:金红美

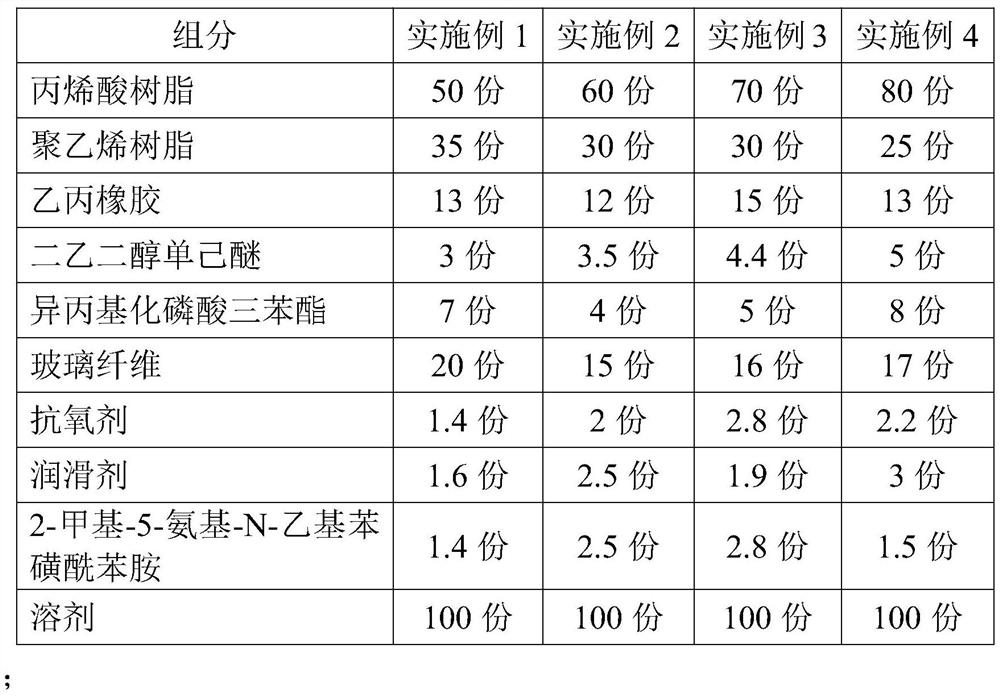

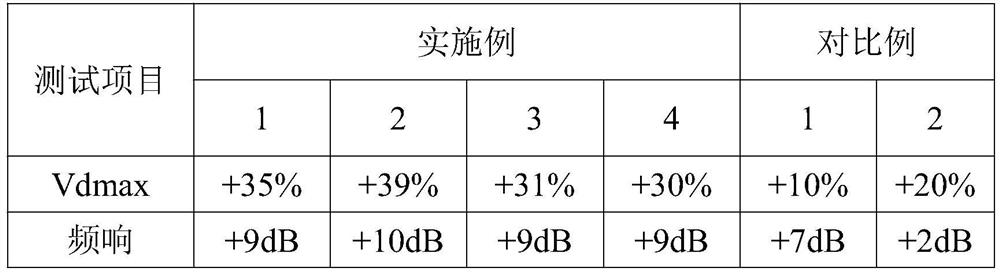

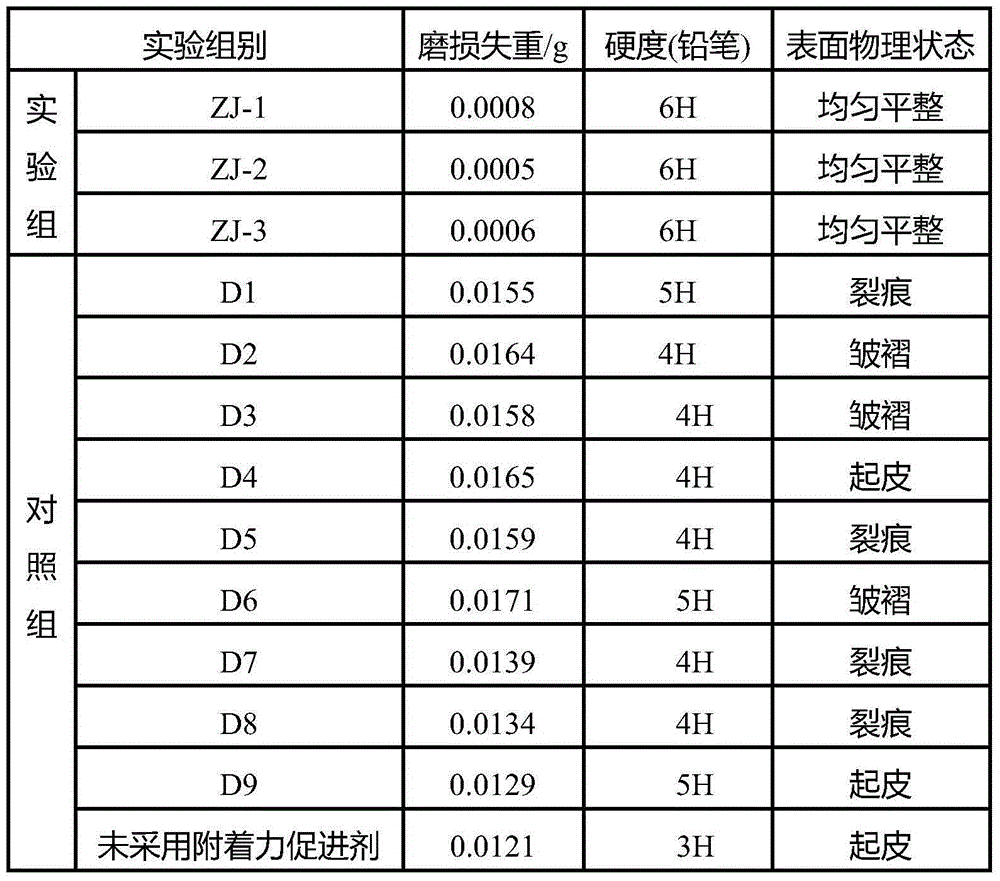

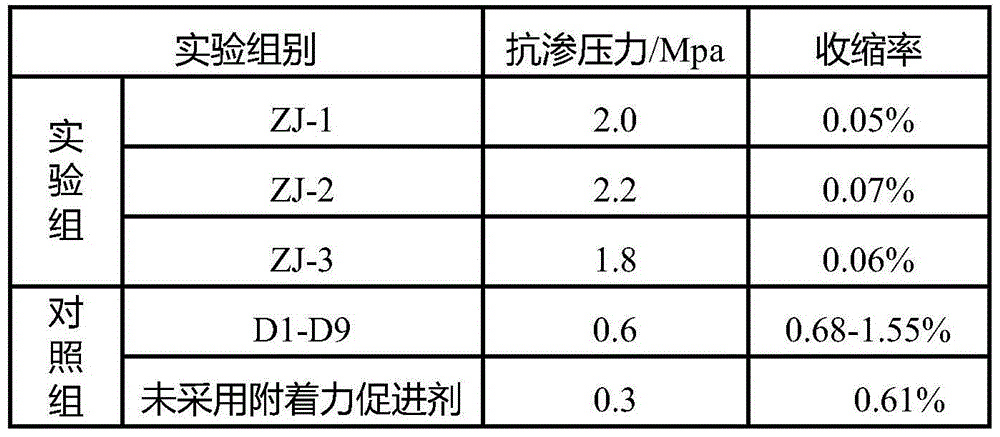

Vibrating diaphragm material and preparation process thereof

PendingCN114363775AIncreased maximum push volumeImprove frequency responseDiaphragm constructionPolymer scienceDiethylene glycol monohexyl ether

The vibrating diaphragm material comprises a vibrating diaphragm coating and a base material layer, and the vibrating diaphragm coating is formed by coating a vibrating diaphragm glue solution. The vibrating diaphragm glue solution is prepared from the following components in parts by weight: 50 to 80 parts of acrylic resin, 25 to 35 parts of polyethylene resin, 10 to 15 parts of ethylene propylene rubber, 3 to 5 parts of diethylene glycol monohexyl ether, 3 to 8 parts of isopropyl triphenyl phosphate, 15 to 20 parts of glass fiber, 1 to 3 parts of antioxidant, 1 to 5 parts of lubricant, 1 to 5 parts of 2-methyl-5-amino-N-ethyl benzenesulfonyl aniline and 100 parts of solvent. According to the diaphragm material disclosed by the invention, the diethylene glycol monohexyl ether and the isopropyl triphenyl phosphate are added into the acrylic resin, the polyethylene resin and the ethylene propylene rubber, so that the maximum pushing volume of a loudspeaker is increased and can be increased by 39% to the maximum; and the frequency response of the loudspeaker is improved and can be increased by 10dB at most.

Owner:CYBRID TECHNOLOGIES INC

Special solder paste for soldering multi-level package SMT components

ActiveCN110653516BReduce manufacturing costEasy to implementWelding/cutting media/materialsSoldering mediaButanedioic acidMetal particle

The invention belongs to a kind of special solder paste for welding multi-level packaging chip components, which is specifically suitable for the application of the service temperature after welding is higher than 240 ℃, including tin alloy, nano metal, rare earth alloy and solder paste, tin alloy The powder is one or a mixture of tin-silver alloy powder, tin-antimony alloy powder, tin-copper alloy powder and tin-lead alloy powder; the nano-metal powder is one of copper powder, lead powder, titanium powder, cobalt powder and gold powder or multiple mixtures; the active ingredients of the described soldering paste include hydrogenated rosin, diethylene glycol monohexyl ether, succinic acid, tolyltriazole and citric acid; its preparation method includes preparing tin alloy powder, Nano-metal powder, rare-earth alloy powder, flux paste and mixing steps, adopting the invention of this technical solution, by adding elemental metal particles or alloy particles to the solder paste, and adding corresponding nano-auxiliary additives, the preparation cost is lower than Nano solder paste is easy to implement and has a wider range of applications.

Owner:深圳群崴半导体材料有限公司

Environment-friendly soldering paste

InactiveCN104923977AImprove welding effectEasy to cleanWelding/cutting media/materialsSoldering mediaBenzoic acidGlutaric acid

An environment-friendly soldering paste is made from the following raw materials, by weight, 3-9 parts of rosin, 6-9 parts of ethyl acetate, 7-9 parts of turpentine, 1-4 parts of antioxidants, 3-9 parts of organic acid active agents, 2.5-6 parts of diethylene glycol monohexyl ether, 0.5-2 parts of magnesium, 5-8 parts of sebacic acid, 4-7 parts of benzotriazole, 7.5-9 parts of glutaric acid, 1-2 parts of ethylamine hydrochloride, 4-9 parts of fluorobenzoic acid, 8-10 parts of dioctyl phthalate, 7-8 parts of modified hydrogenated castor oil, 6-8 parts of alkylphenol ethoxylates and 3-8 parts of alloy soldering powder. The environment-friendly soldering paste has the advantages that the environment-friendly soldering paste is free of toxicity and environmentally friendly, meanwhile, welding performance can be well improved, residues are few after welding, and washing is easy; the environment-friendly soldering paste is widely applied to high-precision electronic components.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Environment-friendly spraying method for construction

ActiveCN103480557BImprove wear resistanceImprove crack resistancePretreated surfacesSpecial surfacesEnvironmental resistanceWear resistant

The invention relates to an environment-friendly spraying method for construction by use of coating additives. The coating additives comprise hydroxypropyl methyl cellulose, modified sulfur powder, nanometer zirconium phosphate composite material, electrical nanometer polycrystalline diamond powder, attapulgite, an additive, ethylene glycol monohexyl ether, glycerol and deionized water; the spraying method has unexpected synergism by combination of the coating additives and proper optimization of technological parameters, the prepared coating has excellent wear-resistant, anti-cracking, ultraviolet-prevention and waterproof effects, can be widely applied to spraying of surfaces such as steel sheets for decoration, wood surface, furnish surface and wallpaper surface, fully meets the requirement of persons for diversified functions and has good industrial application prospect and market value.

Owner:BEIJING SHENGHAO UNIVERSE TECH DEV

Novel paint capable of protecting stainless steel plate from corrosion

InactiveCN108976920ASimple componentsReasonable ratioFireproof paintsStarch coatingsSodium BentoniteMaterials science

The invention discloses novel paint capable of protecting a stainless steel plate from corrosion. The novel paint is prepared from the following raw materials in parts by weight: 7 to 14 parts of cornpowder, 0.4 to 1.1 parts of glycol monohexyl ether, 0.5 to 0.8 part of potassium sulphate, 1.7 to 2.5 parts of propanediol, 3 to 8 parts of anti-cracking fiber, 15 to 19 parts of chlorinated polypropylene resin, 0.4 to 0.7 part of titanium dioxide, 2.3 to 2.7 parts of organic titanate coupling agents, 7 to 11 parts of kaolin, 0.3 to 0.6 part of sodium cetylbenzene sulfonate, 4 to 7 parts of talcum powder, 7 to 11 parts of lime powder, 6 to 10 parts of starch, 5 to 9 parts of gleditsia sinensis, 1.2 to 2.5 parts of tributyl phosphate, 3 to 7 parts of monomers, 9 to 12 parts of bentonite, 0.3 to 0.7 part of ammonium metaborate, 5 to 8 parts of filling agents, 8 to 13 parts of ethylene-propylene chloride rubber, 4 to 8 parts of quartz powder, 0.2 to 0.6 part of carboxymethylcellulose, 0.3 to0.6 part of nanometer silicon dioxide, 0.2 to 0.6 part of mica titanium and 0.4 to 0.9 part of sodium pentachlorophenate. The paint provided by the invention has the advantages that the ingredients are simple; the proportioning is reasonable; good high temperature resistance, cold resistance, corrosion resistance, wear resistance and the like can be realized; the novel paint is suitable for beingused in severe environments; the antirust capability is high; the production cost is relatively low, and the like.

Owner:含山县林宏铸造厂

High-temperature-resistant and oxidation-resistant paint for metals

InactiveCN109456635AEffective oxidationEffective protectionFireproof paintsAnti-corrosive paintsAcrylic resinPolyvinyl alcohol

The invention discloses high-temperature-resistant and oxidation-resistant paint for metals. The paint is prepared from the following raw materials in parts by weight: 6-28 parts of trichloroethane, 3-13 parts of glycern isobutyrate polymer gel, 4-18 parts of polyvinyl alcohol, 2-12 parts of a wetting agent, 3-13 parts of water-soluble resin, 4-18 parts of activated calcium carbonate, 5-15 parts of metal carboxylate, 3-13 parts of titanium dioxide, 2-12 parts of polyamide resin, 3-15 parts of rosin resin, 4-18 parts of nano silica, 4-18 parts of hydrogenated butyl cyanide gum, 2-16 parts of triphenyl phosphite, 3-17 parts of plant essence, 2-18 parts of seaweed mud, 2-18 parts of vinyl triamine, 5-15 parts of hydroxyl acrylic resin, 2-20 parts of maleic acid, 2-14 parts of dimethylethanolamine, 2-16 parts of amide imide, 3-13 parts of vanadium trioxide, 4-16 parts of ethylene glycol monohexyl ether and 4-18 parts of trimethylolpropane. The paint provided by the invention has the advantages of being high-temperature-resistant, oxidation-resistant, corrosion-resistant, and the like.

Owner:含山县鑫冉电机配件厂

A kind of degumming composition and its preparation method and application

InactiveCN107868729BLow costReduce pollutionOrganic non-surface-active detergent compositionsDiethylene glycol monohexyl etherEthyleneglycol monobutyl ether

The invention discloses degumming composition. The degumming composition comprises components in percentage by mass as follows: 21% of dimethyl carbonate, 27% of diethylene glycol monohexyl ether, 47%of ethylene glycol monobutyl ether and 5% of water. The degumming composition is low in cost, short in degumming time and high in seepage force and degumming effect, produces little pollution, is non-corrosion to a matrix and is free of dead angles and residues, and by means of the degumming composition, technical support can be provided for development of an industrial cleaner.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Efficient electronic circuit welding paste

InactiveCN104923981AImprove welding qualityResidue reductionWelding/cutting media/materialsSoldering mediaAlkylphenolPolyamide

The invention discloses efficient electronic circuit welding paste. The welding paste is made of, by weight, 2-6 parts of itaconic acid, 7-9 parts of thickening agents of polyamide wax type, 1.5-3 parts of diethylene glycol mono-hexyl ether, 6-10 parts of hydrogenated rosin, 2-5 parts of cetane-based ammonium bromide, 3-9 parts of alkylphenol polyoxyethylene ether, 5-7 parts of hydrochloride, 1-4 parts of triazole, 0.5-1 part of antioxygen, 7-10 parts of diethylene glycol propyl ether, 2.5-6 parts of tartaric acid, 6-7 parts of hydroquinone, 1.3-5 parts of diethylene glycol, 4-5 parts of flogopite,tertiary butyl 0.5-2 parts of ferromanganese and 6-11 parts of 2-tertiary butyl hydrochinone. The welding paste has the advantages that the welding paste used in an electronic circuit is good in welding quality, little in residue and easy to clean, meanwhile, the welding paste has the inoxidizability and the rheological property, and the safety and environmental protection are achieved.

Owner:QINGDAO TOPLINK INFORMATION TECH

Cooling oil for machining and preparation process thereof

The invention discloses cooling oil for machining and a preparation process thereof. The cooling oil is composed of the following raw materials (by weight): 16-20 parts of industrial base oil, 12-18 parts of ethylene glycol monohexyl ether, 9-14 parts of mica powder, 10-15 parts of aluminium oxide, 8-13 parts of ethanol, 6-12 parts of a cosolvent, 7-12 parts of barium petroleum sulfonate, 9-14 parts of butanol, 5-8 parts of an antioxidant, 8-13 parts of epoxidized soybean oil, 6-12 parts of acrylonitrile, 12-16 parts of silica, 6-12 parts of rosin, and 8-14 parts of graphene. The cooling oil for machining is sprayed on metal contact surfaces and points in the mechanical cutting and peeling process to achieve the effects of cooling metal temperature during cutting and peeling, lubricating the contact surface between metals and improving the success rate of machine parts processing.

Owner:含山县龙顺机械配件厂

Reaction kettle inner wall nano coating and preparation method thereof

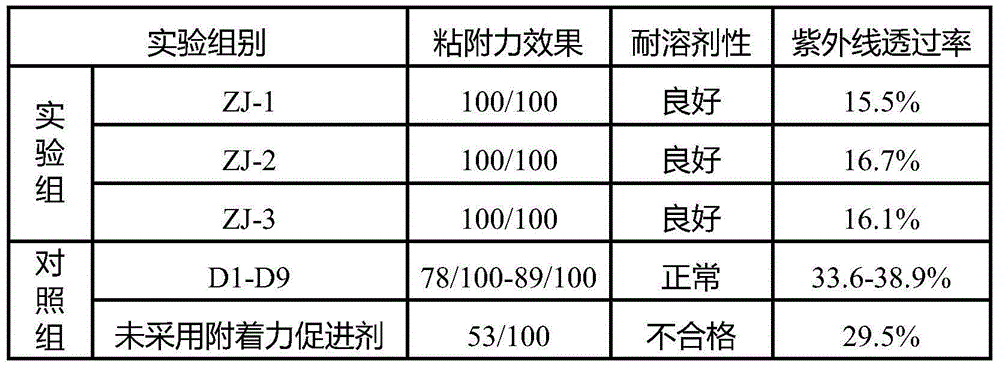

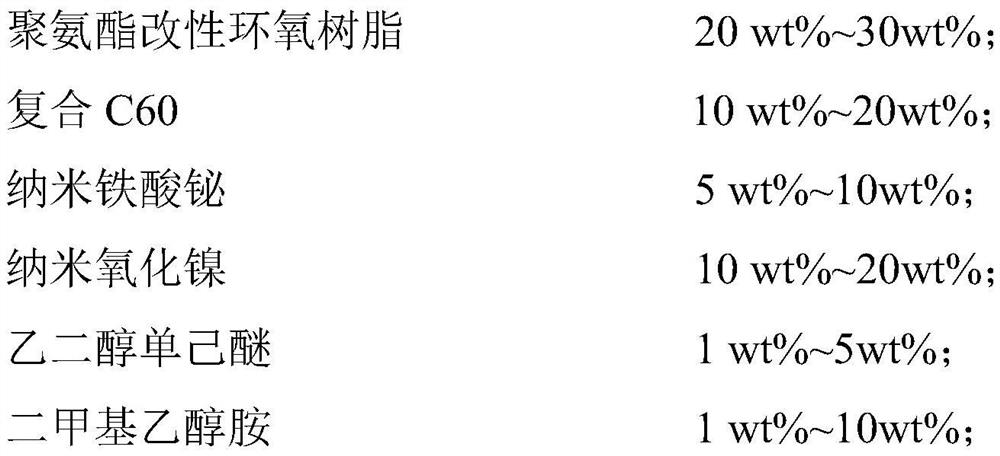

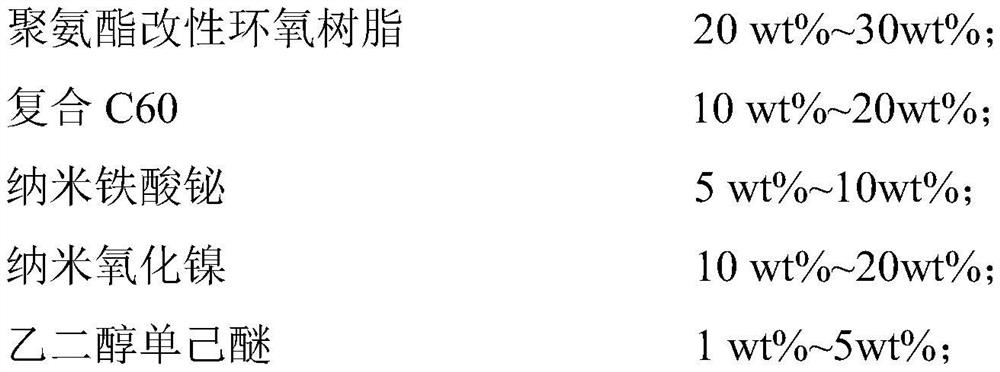

InactiveCN112592640ASimple manufacturing methodReduce coefficient of frictionAnti-corrosive paintsEpoxy resin coatingsEpoxyDimethylethanolamine

The invention provides a reaction kettle inner wall nano coating and a preparation method thereof. The coating comprises the following components in percentage by mass: 20-30wt% of polyurethane modified epoxy resin, 10-20 wt% of composite C60, 5-10 wt% of nano bismuth ferrite, 10-20 wt% of nano nickel oxide, 1-5 wt% of ethylene glycol monohexyl ether, and 1-10 wt% of dimethylethanolamine; and a solvent. According to the reaction kettle inner wall nano coating, the nano bismuth ferrite and the nano nickel oxide are added into the surface coating, so that the effect of reducing the friction coefficient can be achieved, a self-lubricating material is formed, and even a super-lubricating function is obtained, and therefore, the nano coating for the inner wall of the reaction kettle is not easyto absorb water, easy to clean and resistant to acid and alkali. The preparation method of the reaction kettle inner wall nano coating is simple and feasible, green and environmentally friendly, andis an environment-friendly process.

Owner:昆山市锦宏压力容器制造有限公司

Aluminum-based glass cleaning agent and preparation method thereof

PendingCN114085716AEasy to useImprove cleaning efficiencyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphateDiethylene glycol monohexyl ether

The invention relates to the technical field of glass cleaning agents, in particular to an aluminum-based glass cleaning agent and a preparation method thereof. The cleaning agent is prepared from the following formula components in parts by weight: starch octenyl succinate, sodium sulfate, acetone, ethylene glycol tert-butyl ether, diethylene glycol monohexyl ether, polyoxyethylene nonylphenol phosphate, polyamide polyamine epichlorohydrin, softened water, potassium carbonate and water. The components of the formula are added into a reaction kettle, stirring and heating reaction are carried out, and uniform mixing is carried out to obtain the glass cleaning agent. The invention solves the problems that existing aluminum-based glass cleaning agents leave marks on glass and and use of the glass is affected. The aluminum-based surface cleaning efficiency is improved by the cleaning agent provided by the invention, meanwhile, dirt residues can be avoided, secondary cleaning of the glass is not needed, and the cleaning efficiency is high.

Owner:厦门普诺尔新材料科技有限公司

A kind of nanoparticle doping realizes high temperature service solder paste and preparation method thereof

ActiveCN110508973BReduce manufacturing costEasy to implementWelding/cutting media/materialsSoldering mediaButanedioic acidDiethylene glycol monohexyl ether

The invention belongs to a kind of nano-particle doping to achieve high-temperature service solder paste, which is specifically suitable for applications where the service temperature after welding is higher than 270°C, including tin alloys, nano-metals, rare earth alloys and solder pastes. The tin alloy powder It is a mixture of one or two kinds of tin-silver alloy powder, tin-antimony alloy powder and tin-copper alloy powder; the nano-metal powder is one or more mixtures of copper powder, nickel powder, titanium powder, cobalt powder and gold powder; The active ingredients of the solder paste include hydrogenated rosin, diethylene glycol monohexyl ether, succinic acid, tolyltriazole and citric acid; its preparation method includes preparing tin alloy powder, nanometer metal powder, rare earth alloy Powder, flux paste and mixing steps, adopting the invention of this technical scheme, by adding a certain proportion of nano-element metal particles or alloy particles in the solder paste, and adding corresponding nano-auxiliary additives, the preparation cost is lower than that of nano-soldering Paste, and easy to implement, a wider range of applications.

Owner:CHONGQING QUNWIN ELECTRONICS MATERIAL CO LTD

No-clean high-temperature electronic soldering flux and preparation method thereof

InactiveCN106271219ASolder joints are fullNo retractionWelding/cutting media/materialsSoldering mediaSodium BentonitePolyethylene glycol

The invention discloses a no-clean high-temperature electronic soldering flux and a preparation method thereof. The electronic soldering flux comprises the following raw materials: bismuth chloride, tin fluosilicate, tin methanesulfonate, titanium dioxide, glass fiber reinforced plastics powder, zirconium acetylacetone, 1-benzyl hydantoin, polyethylene glycol oleate, organic bentonite, dicyl polyglycoside, poly (3, 4-ethylenedioxythiophene)- polystyrolsulfon acid, trisruthenium chloride, diethylene glycol monohexyl ether, dipropylene glycol monomethyl ether, pamite, N-N-dimethylacetamide, disproportionate rosin potassium, methyl diethanolamine, lauroyl diethanolamine, 1-N- hydroxybenzotriazole and barium dinonylnaphthalenesulfonate. In a brazing process, the soldering flux prepared by the preparation method disclosed by the invention releases little chemical salt fog, and is full in welding points, free of corrosion and retraction phenomenon, high in wetting force, large in shear strength, excellent in welding assistance performance, free of residual welding points after brazing, bright in surface, clean enough to require no subsequent cleaning procedure, and convenient to use.

Owner:王泽陆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com