M30 methanol gasoline corrosion inhibitor

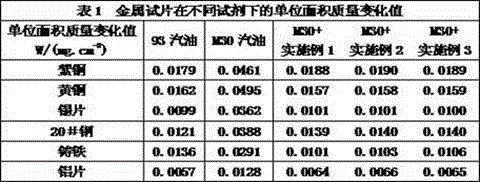

A corrosion inhibitor, methanol gasoline technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as automotive metal corrosion, and achieve good anti-corrosion performance, anti-corrosion problems, and excellent anti-oxidation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take 8 kg of petroleum ether, 12 kg of 2-chloro-4-nitroimidazole, 16 kg of diethylene glycol monohexyl ether, 12 kg of trimethylolpropane monoallyl ether, dialkyl dithio 7 kg of zinc phosphate and 9 kg of dibenzofuran were added to the reaction kettle and ultrasonically sealed and stirred at 52-55°C for 20-30 minutes to obtain liquid A;

[0023] Take 6 kg of creatine hexaphosphate, 8 kg of heptamethyldisilazane, and 12 kg of aminoacetaldehyde diethyl acetal, stir and react at 66-68°C for 25-35 minutes to obtain liquid B;

[0024] (2) Add liquid A and liquid B together with 12 kg of 2-octanol and 10 kg of ethylene glycol ether into the reaction kettle and stir for 15 to 25 minutes at 32 to 38°C to obtain the product.

Embodiment 2

[0026] (1) Take 6 kg of petroleum ether, 12 kg of 2-chloro-4-nitroimidazole, 15 kg of diethylene glycol monohexyl ether, 10 kg of trimethylolpropane monoallyl ether, dialkyl dithio 7 kg of zinc phosphate and 8 kg of dibenzofuran were added to the reaction kettle and ultrasonically sealed and stirred at 52-55°C for 20-30 minutes to obtain liquid A;

[0027] Take 5 kg of creatine hexaphosphate, 6 kg of heptamethyldisilazane, and 10 kg of aminoacetaldehyde diethyl acetal, stir and react at 66-68°C for 25-35 minutes to obtain liquid B;

[0028] (2) Put liquid A and liquid B together with 10 kg of 2-octanol and 10 kg of ethylene glycol ether into the reaction kettle and stir at 32-38°C for 15-25 minutes to obtain the product.

Embodiment 3

[0030] (1) Take 9 kg of petroleum ether, 15 kg of 2-chloro-4-nitroimidazole, 18 kg of diethylene glycol monohexyl ether, 13 kg of trimethylolpropane monoallyl ether, dialkyl dithio 10 kg of zinc phosphate and 9 kg of dibenzofuran were added to the reaction kettle and ultrasonically sealed and stirred at 52-55°C for 20-30 minutes to obtain liquid A;

[0031] Take 8 kg of creatine hexaphosphate, 9 kg of heptamethyldisilazane, and 13 kg of aminoacetaldehyde diethyl acetal, stir and react at 66-68°C for 25-35 minutes to obtain liquid B;

[0032] (2) Put liquid A and liquid B together with 13 kg of 2-octanol and 13 kg of ethylene glycol ether into the reaction kettle and stir at 32-38°C for 15-25 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com