Image sensor and manufacturing method thereof

A technology of an image sensor and a manufacturing method, which is applied to electric solid-state devices, semiconductor devices, radiation control devices, etc., can solve problems such as leakage and low efficiency, and achieve the effects of improving isolation efficiency and reducing dark current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

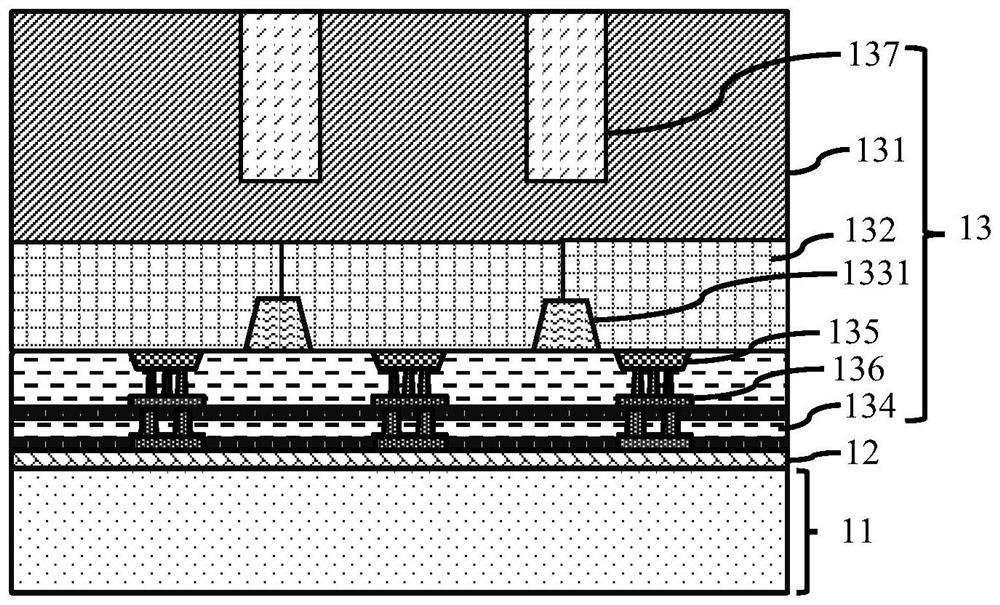

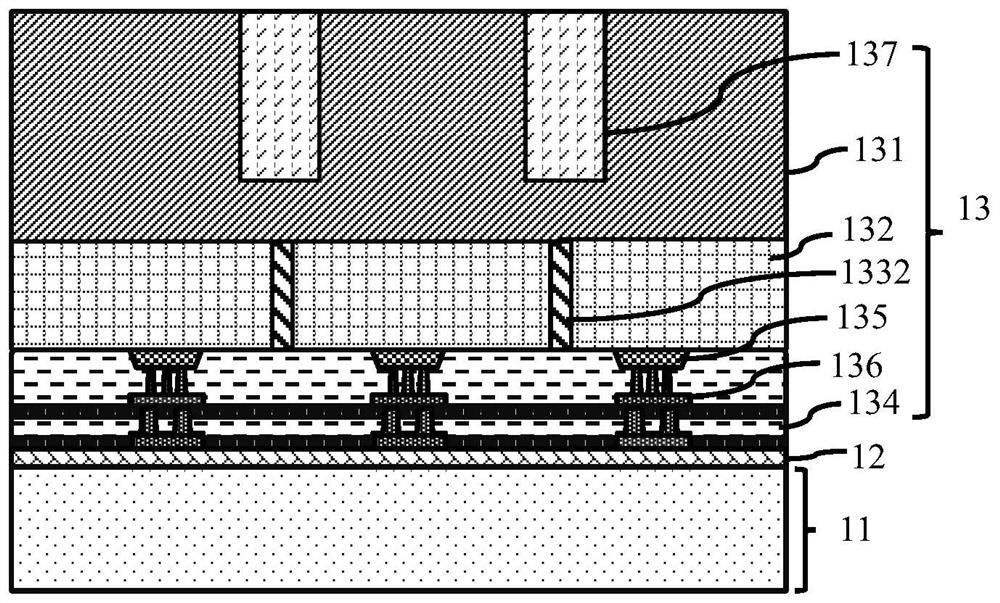

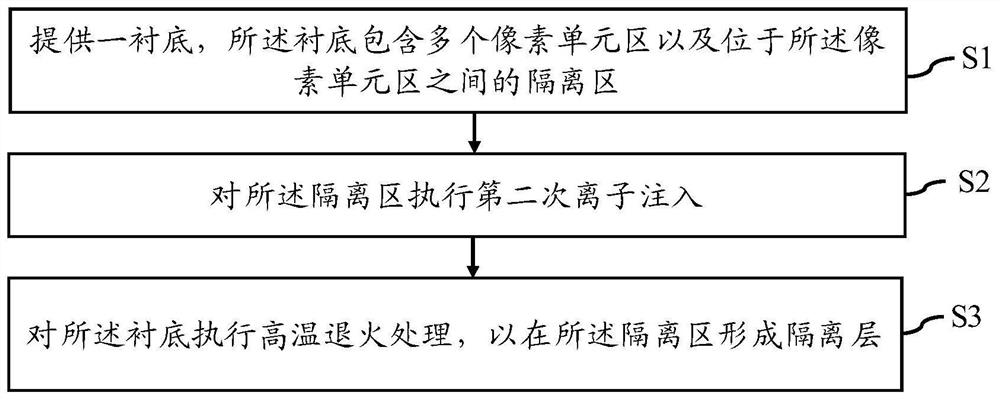

[0050] by Figure 1a ~ Figure 1b shown in the existing image sensor structure as an example, and Figure 1a ~ Figure 1b Shown is the structure of a back-illuminated image sensor, where, Figure 1a Each pixel in the shown image sensor is isolated by a shallow trench isolation structure, Figure 1b The pixel points in the image sensor shown are separated by doping regions formed by inversion ion implantation. From Figure 1a and Figure 1b It can be seen from the figure that the front side of the carrier wafer 11 and the device wafer 13 are bonded through the bonding layer 12, and the device wafer 13 includes a substrate 131 and a plurality of pixel unit regions 132 (ie, pixel points) located on the front side of the substrate 131 , a dielectric layer 134 formed on the pixel unit area 132, a transistor structure 135 and a metal interconnection structure 136 formed in the dielectric layer 134, and a deep trench isolation structure 137 is also formed in the substrate 131 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com