Method for synthesizing o-methylphenylacetic acid

A technology of o-toluic acid and o-tolyl acetonitrile, applied in the field of synthesizing o-toluic acid, can solve problems such as prolonging synthesis time, difficult processing of a stirring shaft, inability to adjust temperature in time, avoiding excessively high temperature, The effect of shortening synthesis time and facilitating rapid temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

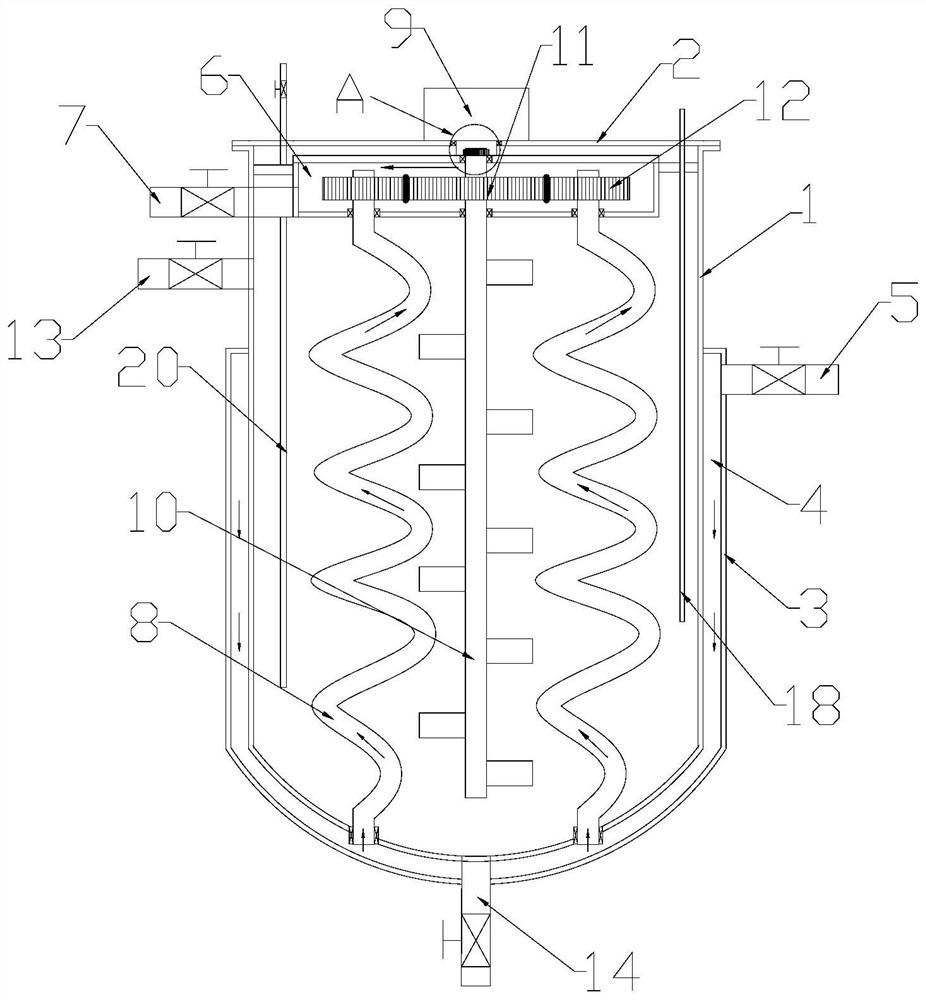

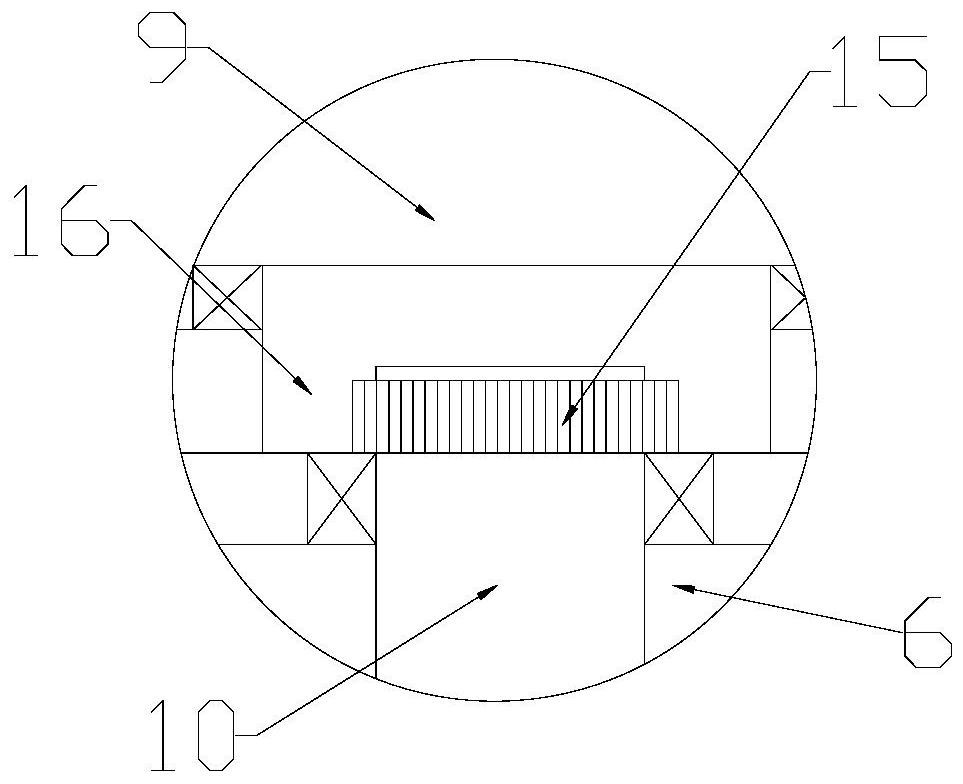

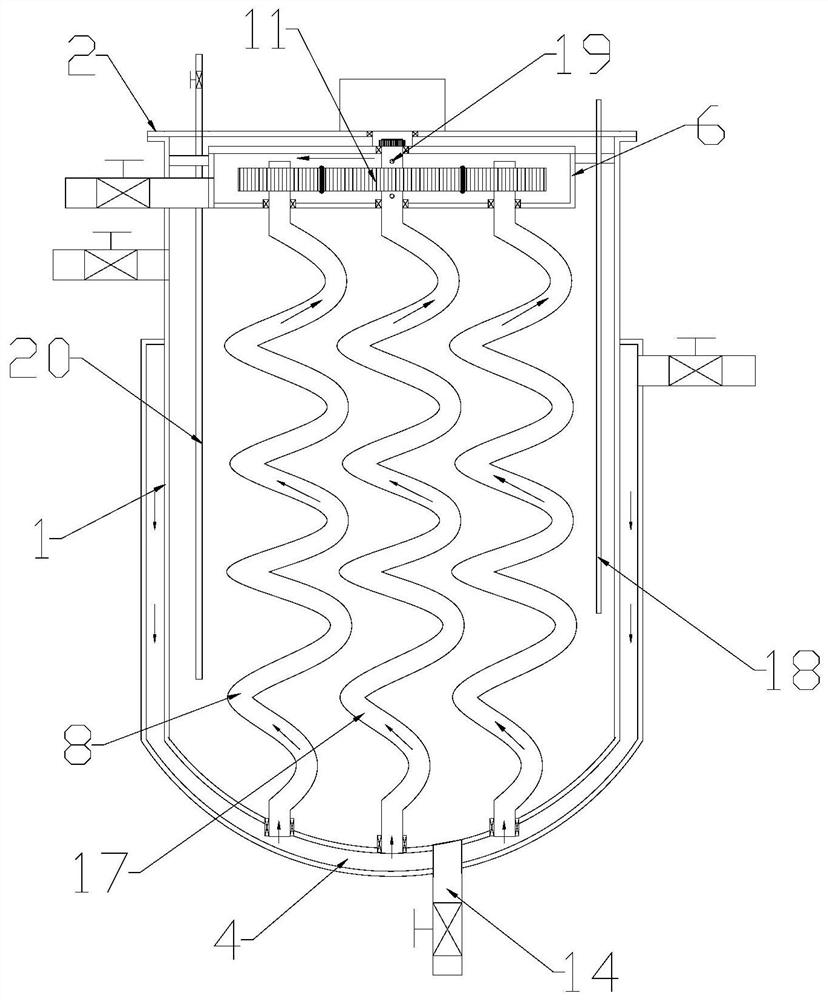

Method used

Image

Examples

Embodiment 1

[0029] A method for synthesizing o-methylphenylacetic acid, comprising the following steps:

[0030] (1) Place o-methyl benzyl chloride and sodium cyanide aqueous solution in a reaction kettle, under stirring conditions, the temperature is controlled at 90°C, and the catalyst is added dropwise to synthesize o-methyl benzyl acetonitrile, the synthesis time is 80min, and the catalyst is tetrabutyl The molar ratio of ammonium bromide, o-methylbenzyl chloride, sodium cyanide: tetrabutylammonium bromide is 1:1.15:0.012, and the mass ratio of sodium cyanide to water is 1:1.8;

[0031] (2) o-methylphenylacetonitrile is prepared by hydrolysis reaction to o-methylphenylacetic acid.

[0032] In step (2), o-tolylacetic acid can be prepared by the method described in CN200610124563.7, or o-tolylacetic acid can be prepared by the method described in CN102476991B.

Embodiment 2

[0034] This example is basically the same as Example 1, except that in step (1), the temperature is controlled at 85° C., and the catalyst is added dropwise to synthesize o-tolueneacetonitrile, and the synthesis time is 100 minutes.

Embodiment 3

[0036] This example is basically the same as Example 1, except that in step (1), the temperature is controlled at 87° C., and the catalyst is added dropwise to synthesize o-tolueneacetonitrile, and the synthesis time is 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com