Preparation method of sludge-based metal organic framework material

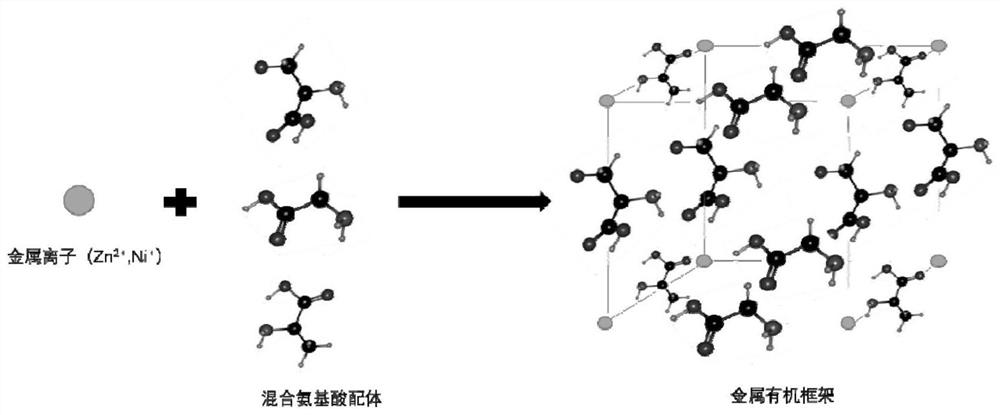

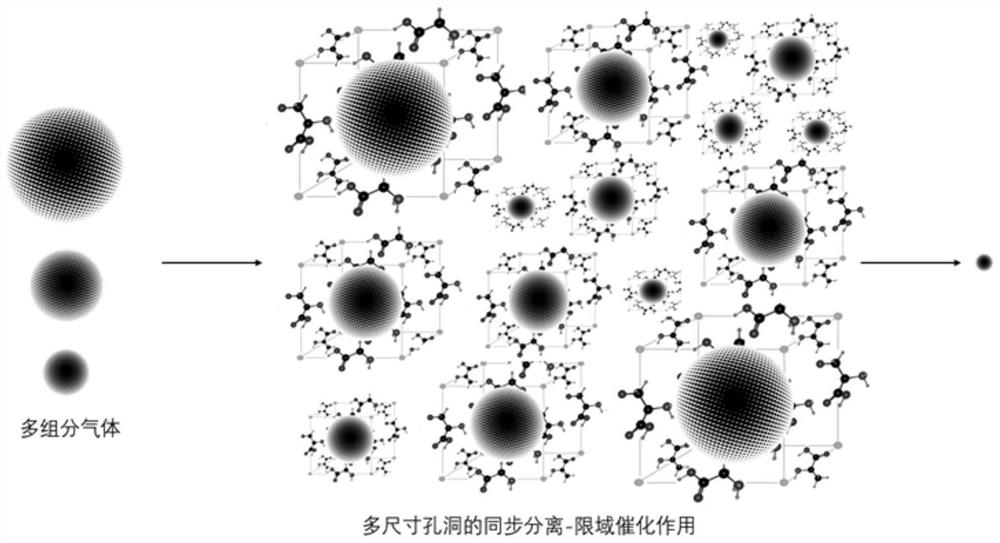

A metal-organic framework and organic framework technology, applied in the field of sludge recycling, can solve the problem of the safe and harmless disposal rate of sludge being less than 30%, and achieve the improvement of the density of catalytic active sites, the simple preparation process, and the improvement of stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a sludge-based metal-organic framework material, specifically comprising the following steps:

[0028] Use an electronic balance to weigh 20g of municipal sludge samples (water content 90%), filter through a sieve with a diameter of 7mm, separate impurities and then homogenize the sludge by stirring. Add concentrated sulfuric acid to adjust the pH of the liquid sample to 0.5, put it in a hydrothermal reaction kettle, and react at 130°C for 4 hours. After it is naturally cooled to room temperature, move the liquid to the reflux device, and continue to add concentrated sulfuric acid to make its concentration 4mol / L, heating and reflux reaction for 20 hours, after the reaction, naturally cool to room temperature, take a small amount of liquid to measure its amino acid content by ninhydrin colorimetry, and dissolve the remaining liquid in N, N-dimethyl formaldehyde after lyophilization In the amide solution, add zinc nitrate hexahydrate and terephthal...

Embodiment 2

[0030] A method for preparing a sludge-based metal-organic framework material, specifically comprising the following steps:

[0031] Use an electronic balance to weigh 20g of municipal sludge samples (water content 85%), filter through a sieve with a diameter of 7mm, separate impurities and then homogenize the sludge by stirring. Add concentrated sulfuric acid to adjust the pH of the liquid sample to 1.5, put it into a hydrothermal reaction kettle, and react at 125°C for 5 hours. After it is naturally cooled to room temperature, move the liquid to the reflux device, and continue to add concentrated sulfuric acid to make its concentration 4 mol / L, heat and reflux for 16 hours, after the reaction, cool naturally to room temperature, take a small amount of liquid to measure its amino acid content by ninhydrin colorimetry, and dissolve the remaining liquid in N,N-dimethyl formaldehyde after lyophilization In the amide solution, add zinc nitrate hexahydrate and 2-methylimidazole at...

Embodiment 3

[0033] A method for preparing a sludge-based metal-organic framework material, specifically comprising the following steps:

[0034] Use an electronic balance to weigh 20g of municipal sludge samples (water content 95%), filter through a sieve with a diameter of 7mm, separate impurities and then homogenize the sludge by stirring. Add concentrated sulfuric acid to adjust the pH of the liquid sample to 1, put it into a hydrothermal reaction kettle, and react at 135°C for 3 hours. After it is naturally cooled to room temperature, move the liquid to the reflux device, and continue to add concentrated sulfuric acid to make its concentration 4mol / L, heating and reflux reaction for 24 hours, after the reaction, naturally cool to room temperature, take a small amount of liquid and measure its amino acid content by ninhydrin colorimetry, and dissolve the remaining liquid in N,N-dimethyl formaldehyde after lyophilization In the amide solution, add zinc nitrate hexahydrate and triethylam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com