A kind of polyurethane sole stock solution and its preparation method and use method

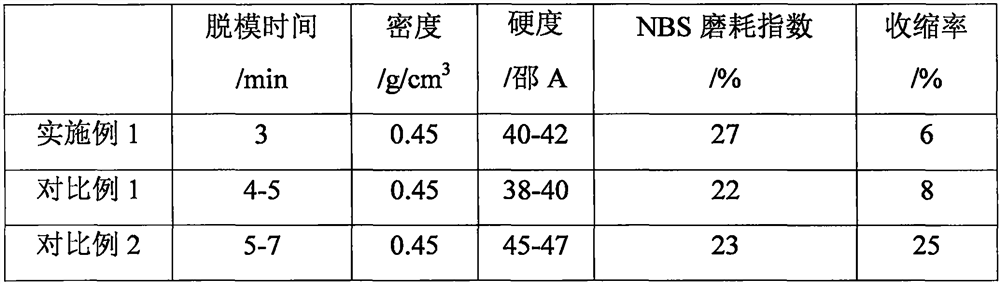

A polyurethane and stock solution technology, applied in the field of polyurethane elastomers, can solve the problems of unsuitable preparation of polyurethane shoe sole stock solution, high shrinkage rate of products, long demoulding time, etc., and achieve high NBS abrasion index, low degree of polymerization, and short demoulding time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

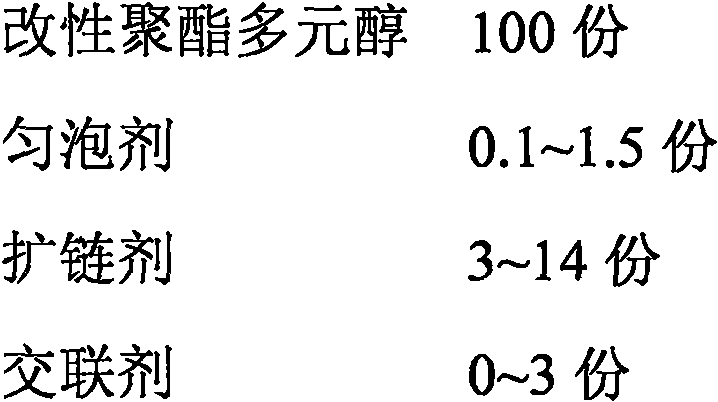

Method used

Image

Examples

Embodiment 1

[0029] The original solution of the polyurethane shoe sole product described in the present embodiment 1, the original solution is composed of the A component and the B component with a weight ratio of A:B=100:83, and the implementation steps are as follows:

[0030] (1) Preparation of modified polyester polyol: dehydrate 2562.5g polyethylene adipate diol with a molecular weight of 1000 at 85-110°C, vacuum degree ≤-0.095MPa, dehydration for 2-4h, moisture 300ppm After cooling down to 40-60°C, under nitrogen protection, add pure 250g MDI, react at 70-100°C for 2.5h, sample and analyze the hydroxyl value of 62.3mgKOH / g to obtain a modified polyester polyol;

[0031] (2) Preparation of component A: 888g polyester polyol prepared in step (1), 2g foam stabilizer DC193, 80g chain extender BDO, 1g crosslinking agent TMP, 5g foaming agent water, 15g catalyst triethylene Diamine was added to the reaction kettle in turn, mixed and stirred at 60-70°C for 1 hour under nitrogen protection,...

Embodiment 2

[0047] The original solution of the polyurethane shoe sole product described in the present embodiment 2, the original solution is composed of the A component and the B component with a weight ratio of A:B=100:89, and the implementation steps are as follows:

[0048](1) Preparation of modified polyester polyol: 1002 g of polytrimethylene adipate diol with a number average molecular weight of 600 and 1002 g of polybutylene adipate diol with a number average molecular weight of 600 were mixed at 85- 110℃, vacuum degree≤-0.095MPa, dehydration for 2-4h, moisture below 300ppm, then cool down to 40-60℃, under nitrogen protection, add 100g of MDI-100 and 317.7g of MDI-50, react at 70-100℃ for 2.5 h, the hydroxyl value of sampling analysis was 77.4 mgKOH / g, and the modified polyester polyol was obtained.

[0049] (2) Preparation of component A: 905g of modified polyester polyol prepared in step (1), 1g of foam stabilizer DC193, 1g of foam stabilizer DC193, 1g of foam stabilizer DC3043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com