Phosphorus-boron heterochain prepolymer block polyurethane flame-retardant regenerated wood-plastic composite material as well as preparation method and application thereof

A technology of plastic composite materials and recycled plastics, which is applied in the field of phosphorus-bora chain prepolymer block polyurethane flame-retardant recycled wood-plastic composite materials and its preparation, which can solve the problems of flammability and fire hazards, and improve water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

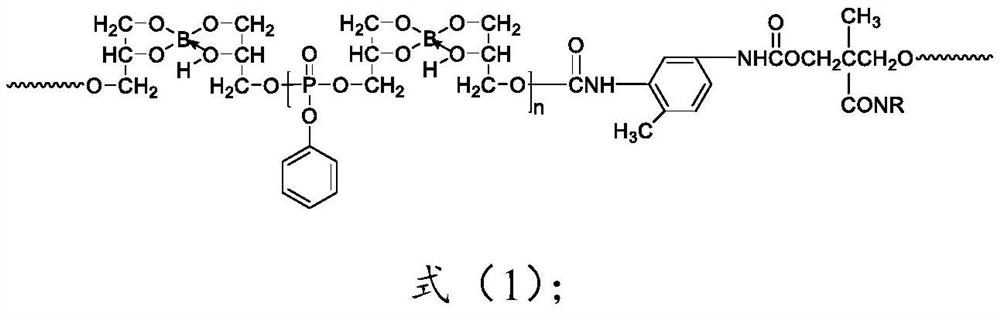

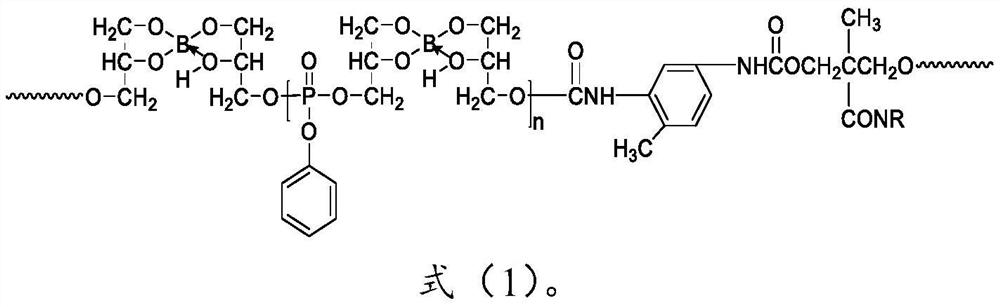

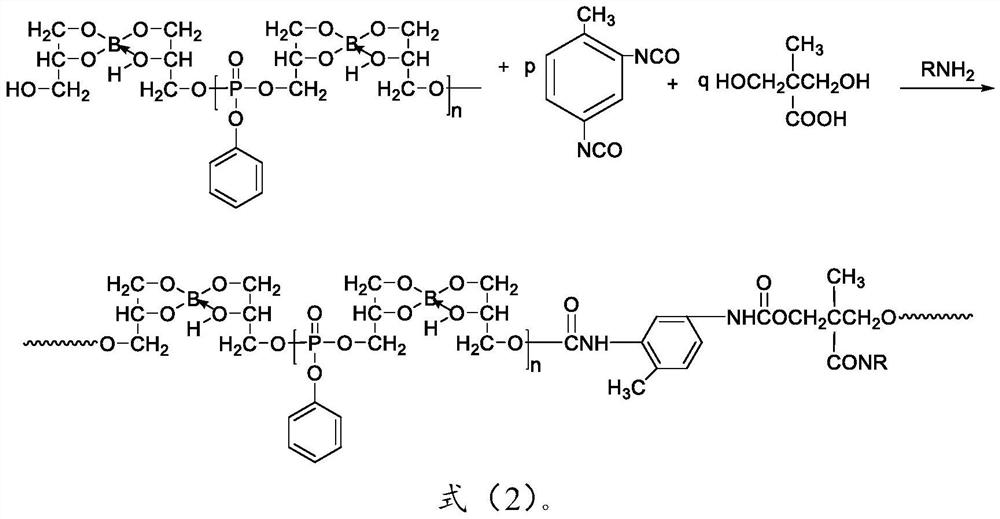

Method used

Image

Examples

no. 1 example

[0046] 1. The preparation of phosphorus bora chain prepolymer block polyurethane waterborne polymer flame retardant comprises the following steps:

[0047] (1) In a four-neck flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 50ml xylene, 45.5gPDCP-DGB, dilauric acid with a ratio of 1:0.01 to TDI Dibutyltin.

[0048] (2) Turn on stirring and blow nitrogen, and heat the reaction system in step (1) to 60±1°C in a water bath. After the heat preservation system is uniform, add 10.3g TDI and 4.0gDMPA dropwise within 30min, keep the system temperature at 75±1°C, and keep warm for 2h , separation and recovery of the upper xylene.

[0049] (3) Cool down the reaction system after separation and removal of xylene to 45±1°C, then add monoethanolamine and 50ml of water, continue stirring for 1 hour, adjust the pH=9.0, and then adjust the product viscosity to 1200Cp (25°C) with water , to obtain the phosphorus bora...

no. 2 example

[0056] 1. The preparation of phosphorus bora chain prepolymer block polyurethane waterborne polymer flame retardant comprises the following steps:

[0057] (1) In a four-neck flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 50ml xylene, 46.1gPDCP-DGB, dilauric acid with a ratio of 1:0.03 to TDI Dibutyltin.

[0058] (2) Turn on stirring and nitrogen gas, and heat the reaction system in step (1) to 65±1°C in a water bath. After the heat preservation system is uniform, add 9.7g of TDI and 4.1g of DMPA dropwise within 30 minutes, keep the system temperature at 75±1°C, and keep warm for 1.5 h, separating and recovering the upper layer xylene.

[0059] (3) Cool the reaction system after separation and removal of xylene to 45±1°C, then add monoethanolamine and 50ml of water, continue stirring for 1 hour, adjust pH=8.0, and then adjust the product viscosity to 2200Cp (25°C) with water , to obtain the phosp...

no. 3 example

[0066] 1. The preparation of phosphorus bora chain prepolymer block polyurethane waterborne polymer flame retardant comprises the following steps:

[0067] (1) In a four-neck flask with mechanical stirring, nitrogen protection, condensing reflux, water bath heating and temperature control device, add 50ml xylene, 45.8gPDCP-DGB, dilauric acid with a molar ratio of 1:0.02 to TDI Dibutyltin.

[0068] (2) Turn on stirring and blow nitrogen, and heat the reaction system in step (1) to 60±1°C in a water bath. After the heat preservation system is uniform, add 10.0g TDI and 4.0gDMPA dropwise within 30min, keep the system temperature at 70±1°C, and keep warm for 2.5 h, separating and recovering the upper layer xylene.

[0069] (3) Cool down the reaction system after separation and removal of xylene to 50±1°C, then add monoethanolamine and 50ml of water, continue stirring for 1 hour, adjust the pH=7.5, and then adjust the product viscosity to 2000Cp (25°C) with water , to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com