Novel copper anode mud treatment process

A copper anode slime and new process technology, applied in the field of non-ferrous metal smelting, can solve the problems of increasing processing costs and reducing the direct recovery rate of precious metals, and achieve the effects of improving processing capacity, shortening processing time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

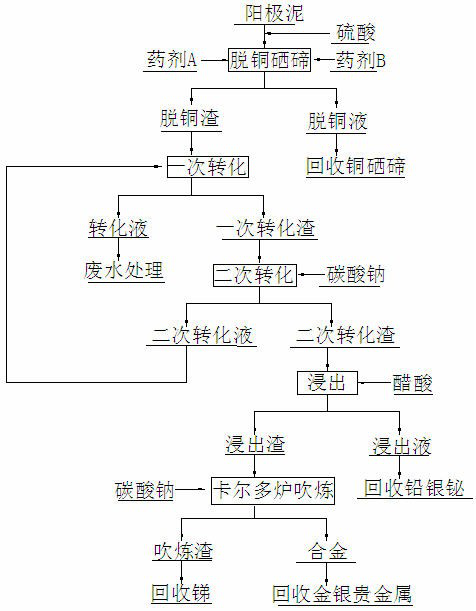

[0031] A new copper anode slime treatment process, such as figure 1 As shown, the process is as follows:

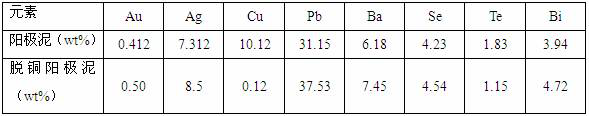

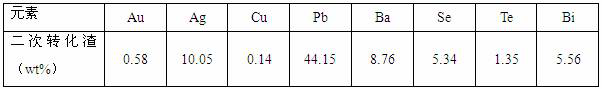

[0032] (1) Wet removal of copper, selenium and tellurium from anode slime

[0033] Take 5 tons of 1# anode slime (see the following table for its composition) and adjust the slurry according to the liquid-solid ratio of 3:1. After the slurry is adjusted, add industrial concentrated sulfuric acid to control the sulfuric acid content in the solution to about 100g / L, and add catalyst KI to control the concentration of 1g / L , heated to 70°C with steam, added 30wt% hydrogen peroxide, the amount was 1.8 times of the theoretical mass, continued to react for 2 hours after all the hydrogen peroxide was added, and obtained 4.15t decoppered anode slime and 13.2m3 copper-containing anode slime after plate and frame filtration The solution of selenium and tellurium, wherein the solution contains 38g / L copper, 1.8g / L selenium, and 3.3g / L tellurium. The main components of decoppered an...

Embodiment 2

[0047] A new copper anode slime treatment process, such as figure 1 As shown, the process is as follows:

[0048] (1) Wet removal of copper, selenium and tellurium from anode slime

[0049] Take 5 tons of 1# anode slime (see the following table for its composition) and adjust the slurry according to the liquid-solid ratio of 3:1. After the slurry is adjusted, add industrial concentrated sulfuric acid to control the sulfuric acid content in the solution to about 150g / L, and add catalyst NaCl to control the concentration of 5g / L , add steam to 70°C, add sodium ferrate, the amount is 1.4 times of the theoretical mass, continue to react for 4 hours after all the sodium ferrate is added, and obtain 4.2t decoppered anode slime and 13.5m³ after plate and frame filtration A solution containing copper, selenium and tellurium, wherein the solution contains 46g / L copper, 2.3g / L selenium, and 4.1g / L tellurium. The main components of the decoppered anode slime are shown in the following t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com