Environment-friendly antibacterial and anti-mite fiber fabric for home textiles

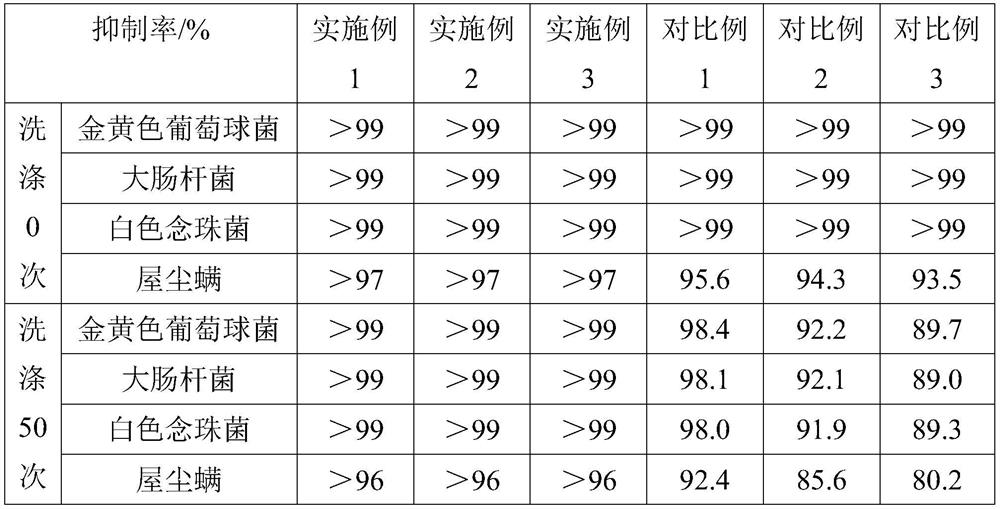

A green environmental protection and anti-mite technology, applied in the field of textile fabric processing, can solve the problems of good washing fastness, poor washing fastness, narrow adaptability, etc., and achieve the effect of durable antibacterial and anti-mite effect and excellent washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

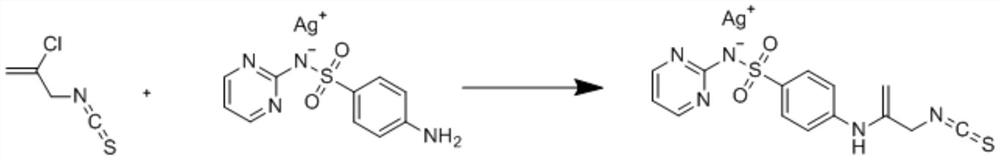

[0027] (1) First dissolve 0.1mol silver sulfadiazine in 5wt% sodium hydroxide solution to obtain solution I, and dissolve 0.1mol 2-chloropropenyl isothiocyanate in N,N-dimethylformamide to obtain Solution II, then add solution I dropwise to solution II, heat to 60°C to react for 24 hours, add water and stir for 30 minutes after the reaction is completed, filter and dry to obtain allyl isothiocyanate silver sulfadiazine monomer. 1 H NMR (DMSO-d6, 400MHz), δ: 12.94(s,1H), 8.84(d,2H), 7.65-7.63(m,3H), 6.89(d,2H), 4.44(d,1H), 4.21 (s,2H), 4.03(s,1H).ESI-MS: m / z=453.95[M+1] + .

[0028] (2) First mix 100 parts of allyl isothiocyanate silver sulfadiazine monomer and 0.5 part of dibenzoyl peroxide evenly and then send them into the twin-screw extruder. 220°C, 230°C in the third zone, 240°C in the fourth zone, and 240°C in the fifth zone, the screw speed is 150rpm, and the feed rate is 15rpm, after melting reaction, extrude and granulate to obtain antibacterial and anti-mite masterb...

Embodiment 2

[0033] (1) First dissolve 0.1mol silver sulfadiazine in 5wt% sodium hydroxide solution to obtain solution I, and dissolve 0.1mol 2-chloropropenyl isothiocyanate in N,N-dimethylformamide to obtain Solution II, then add solution I dropwise to solution II, heat to 60°C to react for 24 hours, add water and stir for 30 minutes after the reaction is completed, filter and dry to obtain allyl isothiocyanate silver sulfadiazine monomer.

[0034] (2) First mix 100 parts of allyl isothiocyanate silver sulfadiazine monomer and 0.5 part of dibenzoyl peroxide evenly and then send them into the twin-screw extruder. 220°C, 230°C in the third zone, 240°C in the fourth zone, and 240°C in the fifth zone, the screw speed is 150rpm, and the feed rate is 15rpm, after melting reaction, extrude and granulate to obtain antibacterial and anti-mite masterbatch.

[0035] (3) Spin the antibacterial and anti-mite masterbatch through the spinning box, the spinning temperature is 260°C, the side blowing temp...

Embodiment 3

[0039](1) First dissolve 0.1mol silver sulfadiazine in 5wt% sodium hydroxide solution to obtain solution I, and dissolve 0.1mol 2-chloropropenyl isothiocyanate in N,N-dimethylformamide to obtain Solution II, then add solution I dropwise to solution II, heat to 60°C to react for 24 hours, add water and stir for 30 minutes after the reaction is completed, filter and dry to obtain allyl isothiocyanate silver sulfadiazine monomer.

[0040] (2) First mix 100 parts of allyl isothiocyanate silver sulfadiazine monomer and 0.5 part of dibenzoyl peroxide evenly and then send them into the twin-screw extruder. 220°C, 230°C in the third zone, 240°C in the fourth zone, and 240°C in the fifth zone, the screw speed is 150rpm, and the feed rate is 15rpm, after melting reaction, extrude and granulate to obtain antibacterial and anti-mite masterbatch.

[0041] (3) Spin the antibacterial and anti-mite masterbatch through the spinning box, the spinning temperature is 260°C, the side blowing tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com