Low-temperature-resistant soft PU (Poly Urethane) barrier film and composite waterproof joint strip

A technology of barrier film and low temperature resistance, applied in the direction of film/sheet adhesive, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problem of windproof, waterproof clothing windproof, waterproof function, windproof, The wearing experience of waterproof clothing is poor, and the PVC barrier layer is easy to crack, etc., to achieve the effect of improving the wearing experience, good elasticity, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

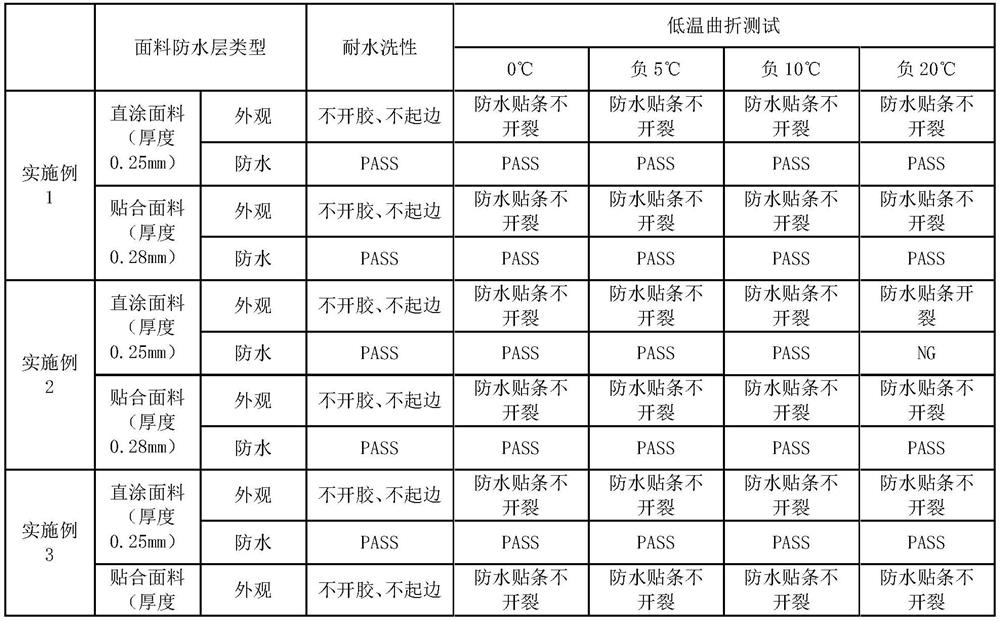

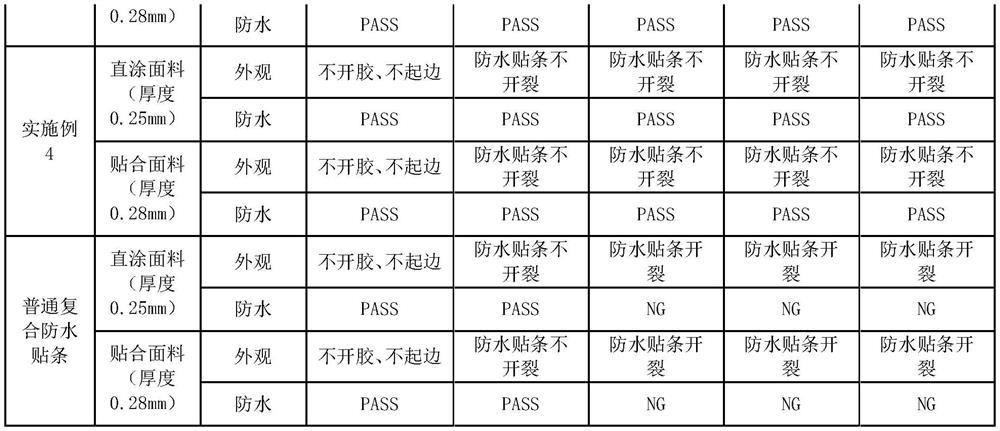

Examples

Embodiment 1

[0028] (1) Add 100 parts of organosilicon polyether polyol (number average molecular weight 1000g / mol) to the reaction kettle, 110 ° C, vacuum stirring for 3H, cool down to 80 ° C, add 50 parts of fatty polyisocyanate, vacuum stirring, when The viscosity of the prepolymer is 7000 mPa.s, and the reaction is stopped by cooling down to obtain a silicone-modified polyurethane prepolymer.

[0029] (2) Mix more than 60 parts of silicone-modified polyurethane prepolymer (viscosity of 7000 mPa.s), 10 parts of aromatic isocyanate (viscosity of 500 mPa.s), 8 parts of ethylene glycol, 0.5 part of γ-glycidyl ether oxygen Propyltrimethoxysilane (KH-560), 0.2 part of diphenyl polysiloxane, 0.5 part of polycarbodiimide, 0.1 part of antioxidant 1010, 0.3 part of UV328 were stirred well, and vacuumed; then the mixture was coated with Cloth on the release paper, drying at 100 ℃ for 15min; then curing at 50±5 ℃ for 24h, remove the release paper to obtain a PU barrier film with a thickness of 0.0...

Embodiment 2

[0031] (1) Add 100 parts of organosilicon polyester polyol (number average molecular weight 1500g / mol) to the reaction kettle, 110 ° C, vacuum stirring for 3H, cool down to 80 ° C, add 60 parts of fatty polyisocyanate, vacuum stirring, when The viscosity of the prepolymer is 10,000 mPa.s, and the reaction is stopped by cooling down to obtain a silicone-modified polyurethane prepolymer.

[0032] (2) 70 parts or more of silicone-modified polyurethane prepolymer (viscosity of 10000mPa.s), 20 parts of aliphatic isocyanate (viscosity of 600mPa.s), 10 parts of 1,4-butanediol, 2 parts of γ- Glycidyl ether oxypropyl trimethoxysilane (KH-560), 0.5 part of diphenyl polysiloxane, 2 parts of polycarbodiimide, 0.5 part of antioxidant 1010, 0.5 part of UV328 were stirred evenly, and vacuumed; Then the mixture was coated on release paper, dried at 120°C for 15min; then aged at 70±5°C for 24h, the release paper was removed to obtain a PU barrier film with a thickness of 0.1mm; the TPU adhesiv...

Embodiment 3

[0034] (1) 50 parts of organosilicon polyether polyols (number-average molecular weight 2000g / mol), 50 parts of organosilicon polyester polyols (number-average molecular weight 1000g / mol) are added in the reactor, 110 ° C, vacuum stirring for 3H, The temperature was lowered to 80° C., 60 parts of aromatic polyisocyanate were added, and the mixture was vacuumed and stirred. When the viscosity of the prepolymer was 15,000 mPa.s, the reaction was stopped by cooling to obtain a silicone-modified polyurethane prepolymer.

[0035](2) 80 parts of poly or more silicone modified polyurethane prepolymer (viscosity of 15000mPa.s), 30 parts of aliphatic isocyanate (viscosity of 800mPa.s), 10 parts of neopentyl glycol, 5 parts of octylsilane Polymer (6608), 1 part of methylphenyl polysiloxane, 3 parts of polycarbodiimide, 1 part of antioxidant 168, 1 part of UV531 were stirred evenly and vacuumed; then the mixture was coated on release paper drying at 150°C for 20min; then curing at 80±5°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com