Integrated all-plastic efficient corrosion-resistant pump

A corrosion-resistant pump, integrated technology, used in non-variable-capacity pumps, pumps, components of pumping devices for elastic fluids, etc., can solve problems such as poor corrosion resistance, damage, and easy corrosion. , to ensure the service life, reduce the cost of use, and have the effect of strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

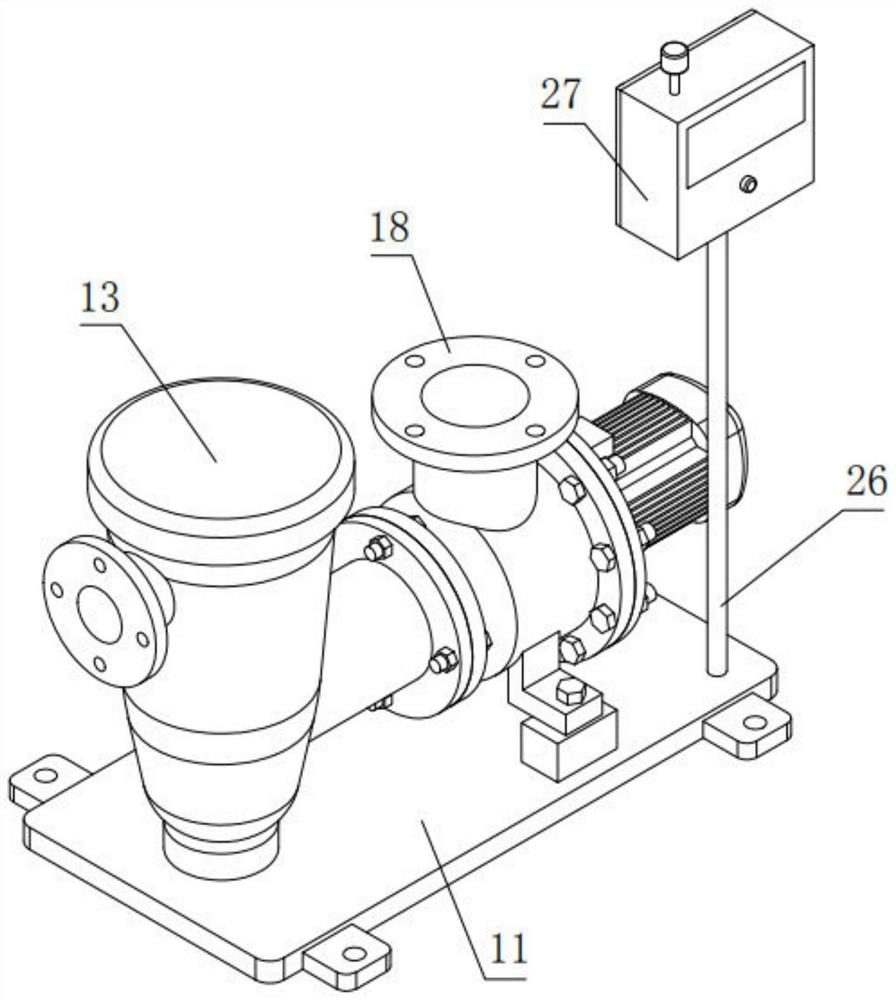

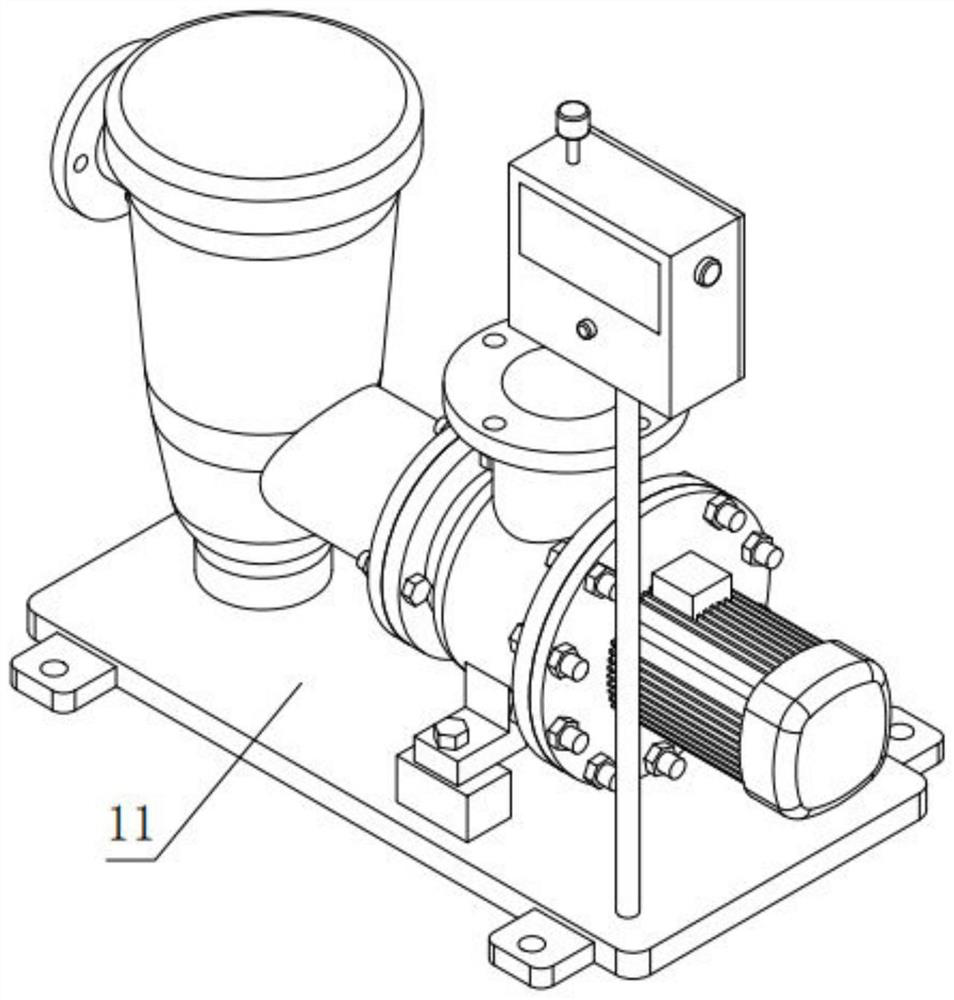

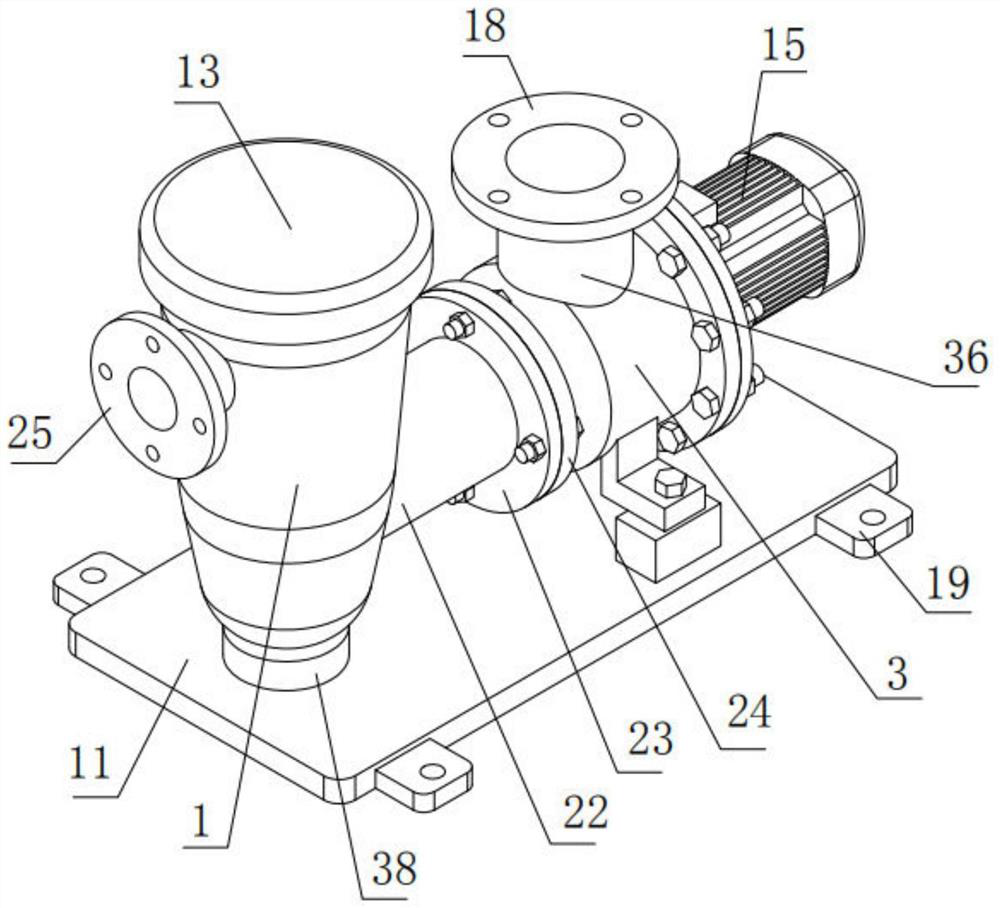

[0040] An integrated all-plastic high-efficiency corrosion-resistant pump according to an embodiment of the present invention includes a pump body structure, a filter mechanism, and an alarm mechanism.

[0041] Among them, the pump body structure includes a bottom plate 11, a pump casing 3, a pump cover 9, a connecting seat 10, a motor 15, a sealing bushing 8, a guide vane 4 and an impeller 6, and the upper part of the bottom plate 11 is fixedly equipped with an assembly block 21, and the pump casing The bottom of 3 is integrally provided with an L-shaped connecting piece 20, and the upper part of the pump casing 3 is integrally provided with a water outlet 36, and one end of the pump casing 3 is provided with a water inlet 37, and the L-shaped connecting piece 20 is fixed on the assembly block by bolts. 21, the water inlet 37 is integrally provided with a first connecting plate 24, the pump cover 9 is fixedly installed on the other end of the pump casing 3 by bolts, and the co...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that the pump body structure further includes a guide ring 5 fixedly installed inside the guide vane 4 , and the inner wall of the guide ring 5 is arranged in close contact with the edge of the impeller 6 .

[0049] By adopting the above technical solution, the impeller 6 can rotate stably under the action of the guide ring 5, so that the working performance of the integrated all-plastic high-efficiency corrosion-resistant pump is relatively stable.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 2 is that the pump body structure further includes a second rubber sealing ring 7 installed at the joint between the pump cover 9 and the pump casing 3 .

[0052] By adopting the above technical solution, under the action of the second rubber sealing ring 7, the connection between the pump cover 9 and the pump casing 3 will not leak, so that the all-plastic all-plastic high-efficiency corrosion-resistant pump has better sealing performance and is not easy to leak. damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com