A semiconductor laser structure

A technology of lasers and semiconductors, which is applied in the direction of semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve the problems of increased internal loss of lasers, increased fast-axis far-field divergence angle, increased device threshold current, etc., to improve output Effects of power and efficiency, increasing fundamental mode limit factor, and reducing threshold current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

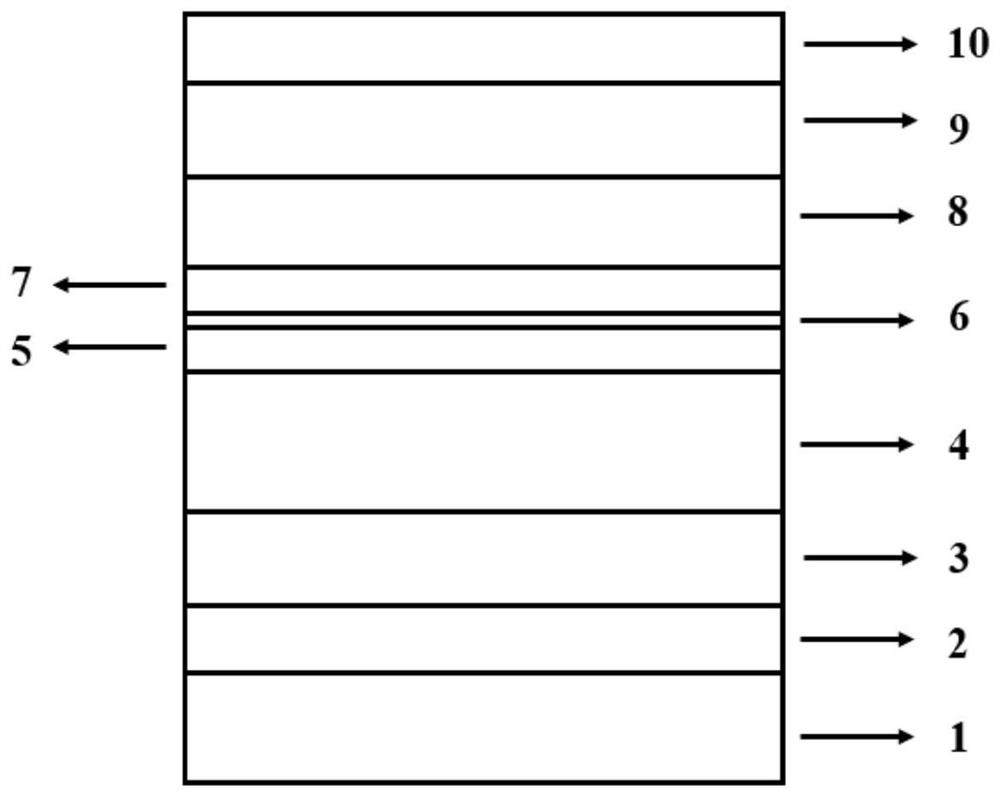

[0034] In this embodiment, a semiconductor laser structure is specifically disclosed, aiming to solve the problems of low fundamental mode confinement factor and high gain of high-order mode modes in the existing large optical cavity waveguide structure 790nm semiconductor laser, such as figure 1 As shown, the structure includes:

[0035] The substrate 1, the buffer layer 2, the lower confinement layer 3, the lower waveguide layer 4, the active layer 6, the upper waveguide layer 8, the upper confinement layer 9 and the ohmic contact layer 10 are arranged respectively from bottom to top, wherein, in the High refractive index layers are respectively embedded between the lower waveguide layer 4 and the active layer 6 and between the active layer 6 and the upper waveguide layer 8, and the active layer 6 is also called a quantum well. The advantage of this design method is that a high refractive index layer is embedded between the active layer 6 and the waveguide layers on both sid...

Embodiment 2

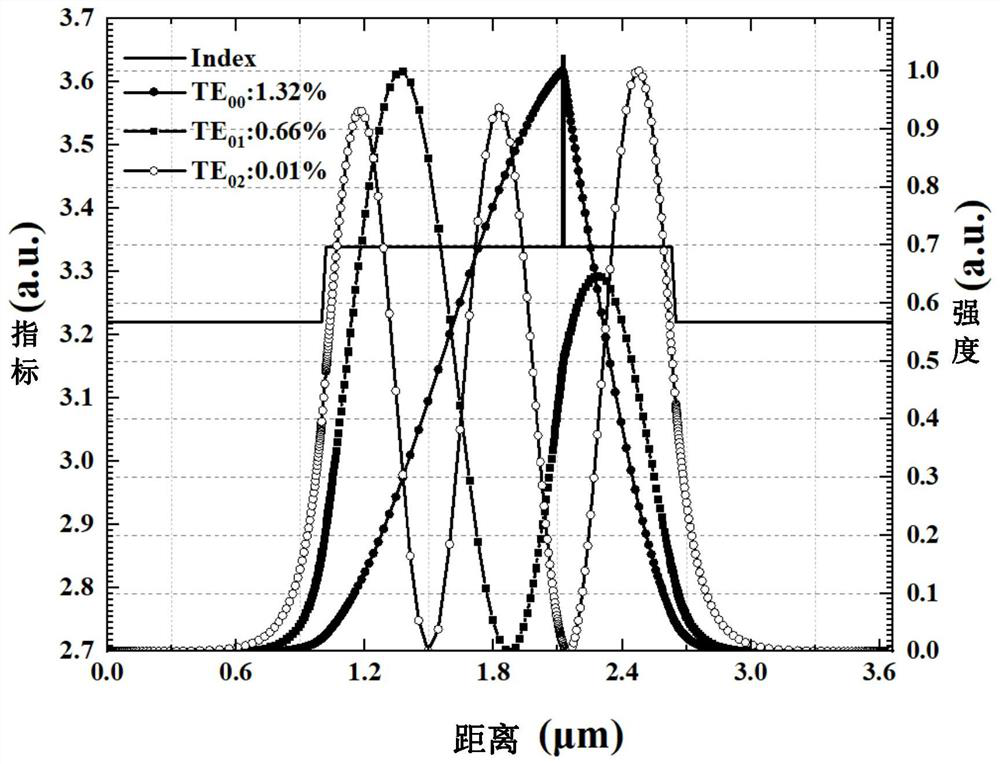

[0056] On the basis of Embodiment 1, in this embodiment, the high refractive index layer, substrate 1, buffer layer 2, lower confinement layer 3, lower waveguide layer 4, active layer 6, upper waveguide layer 8, upper confinement layer Layer 9 and ohmic contact layer 10 are selected as follows:

[0057] ① High refractive index layer

[0058] A high refractive index layer between the upper waveguide layer 8 and the active layer 6, which is unintentionally doped In 0.49 Ga 0.51 As 0.1 P 0.9 material and a thickness of 10 nm; a high refractive index layer between the lower waveguide layer 4 and the active layer 6, which is unintentionally doped In 0.49 Ga 0.51 As 0.1 P 0.9 material and a thickness of 10 nm. Since In 0.49 Ga 0.51 As 0.1 P 0.9 The material layer does not contain Al components, and there is no phenomenon of catastrophic optical damage to the cavity surface easily caused by the oxidation of Al components on the cavity surface;

[0059] The high refractiv...

Embodiment 3

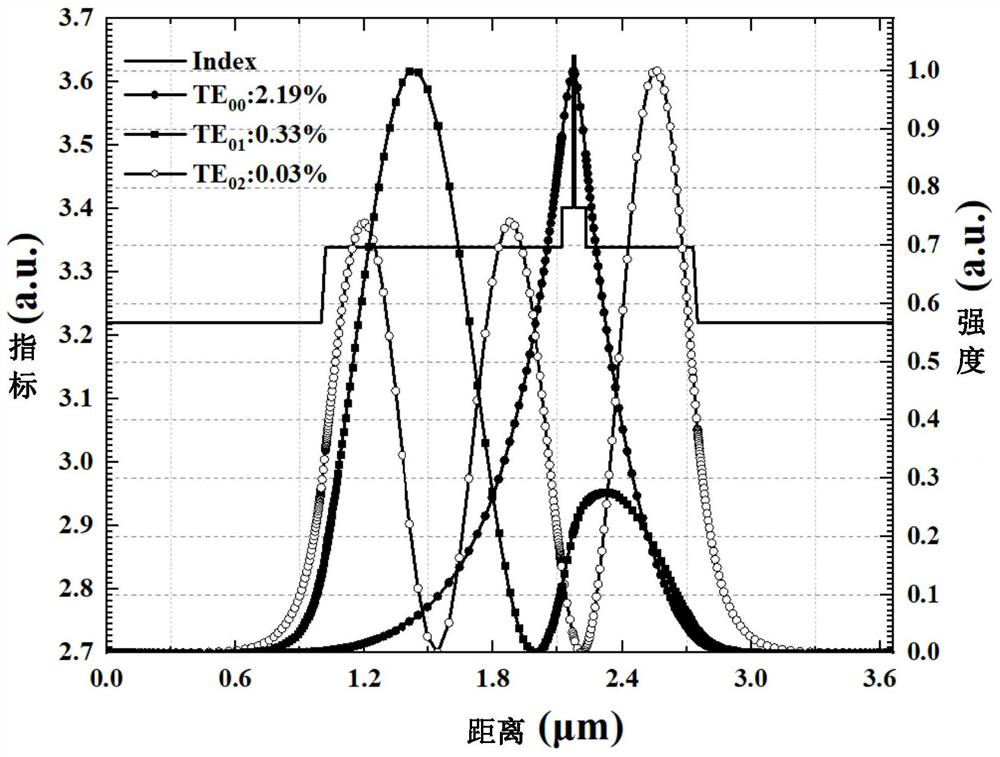

[0073] On the basis of Embodiment 1, in this embodiment, the high refractive index layer, substrate 1, buffer layer 2, lower confinement layer 3, lower waveguide layer 4, active layer 6, upper waveguide layer 8, upper confinement layer Layer 9 and ohmic contact layer 10 are selected as follows:

[0074] ① High refractive index layer

[0075] A high refractive index layer between the upper waveguide layer 8 and the active layer 6, which is unintentionally doped In 0.1 Ga 0.9 As 0.5 P 0.5 material and a thickness of 100 nm; a high refractive index layer between the lower waveguide layer 4 and the active layer 6, which is unintentionally doped In 0.1 Ga 0.9 As 0.5 P 0.5 material and a thickness of 100 nm. Since In 0.1 Ga 0.9 As 0.5 P 0.5 The material layer does not contain Al components, and there is no phenomenon that catastrophic light damage to the cavity surface is easily caused by the oxidation of the Al components on the cavity surface.

[0076] The high refrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com