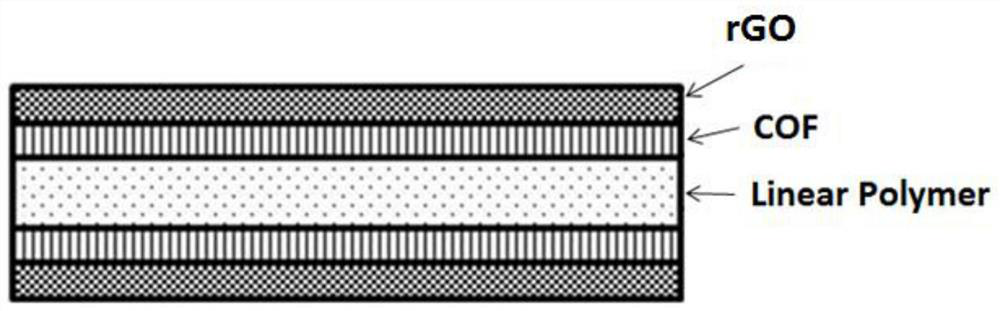

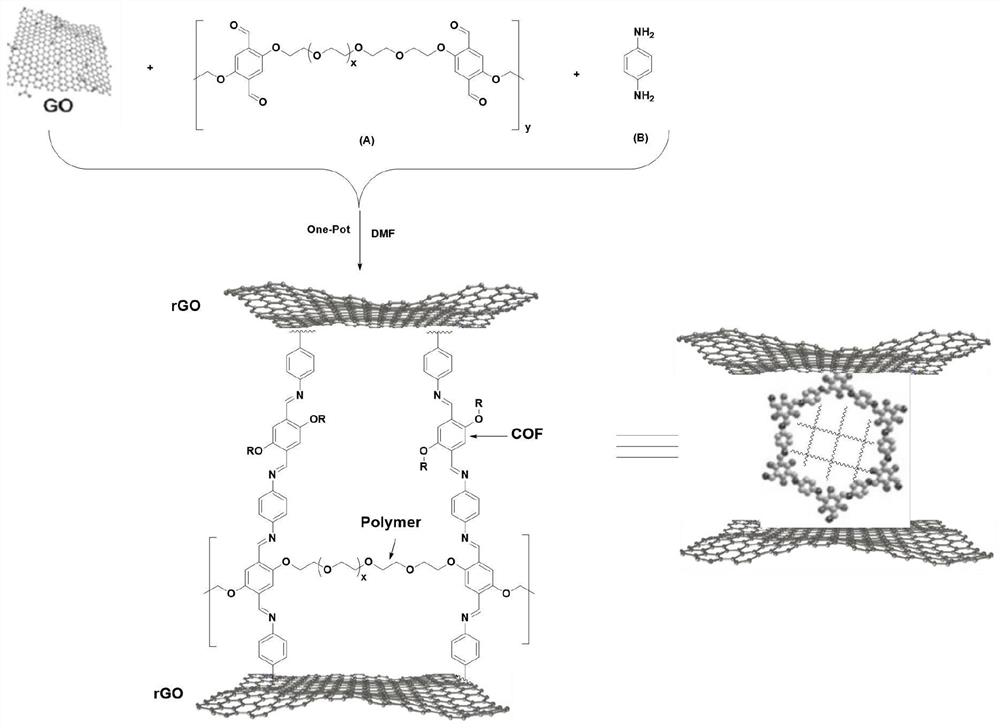

Novel Polymer-COF-rGO composite membrane and preparation method thereof

A composite membrane, a new type of technology, applied in chemical instruments and methods, hydrogen production, hydrogen/synthesis gas production, etc., can solve the problem of composite membrane mechanical strength and stability to be improved, membrane material pore size strong hydrophobicity, small contact area And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

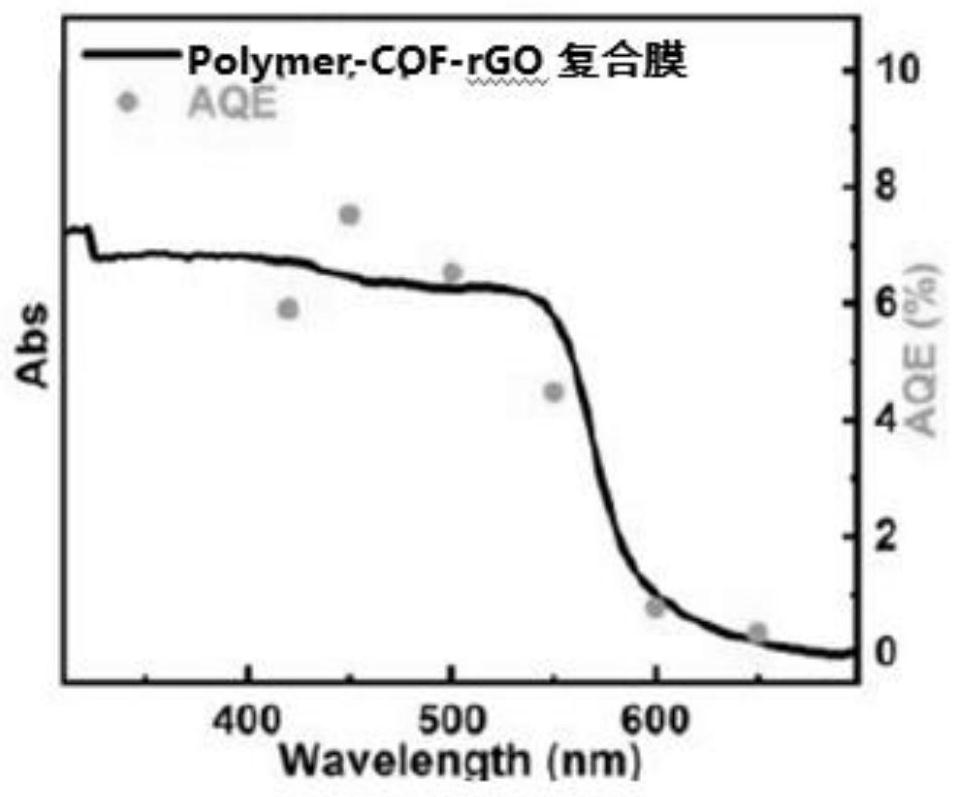

Examples

Embodiment 1

[0027] Step 1: Preparation of Graphene Oxide GO

[0028] 20g of natural graphite and 10g of sodium nitrate (NaNO 3 ) into a 5000mL three-necked flask and cooled to 0°C. Then, slowly add 500mL of concentrated sulfuric acid (H 2 SO 4 ). Thoroughly stir for 30 minutes while controlling the temperature of the reaction system not to exceed 5°C. Then 3 g potassium permanganate (KMnO 4 ) into the three-necked flask, and stirred for 30 minutes while keeping the temperature of the reaction system not exceeding 10°C. Finally, 70g of potassium permanganate (KMnO 4 ) into the three-necked flask. Add in 4 batches within 1 hour while maintaining stirring, and the temperature of the reaction system does not exceed 20°C. It was then stirred at about 35°C for 2 hours to give a brown suspension. After 2 hours, 900 ml of deionized water was slowly added to the three-necked flask, and the temperature of the system rose rapidly to 90 °C, accompanied by a large amount of gas generation. T...

Embodiment 2

[0035] Step 1: Preparation of Graphene Oxide (GO)

[0036] 20g of natural graphite and 10g of sodium nitrate (NaNO 3) into a 5000mL three-necked flask and cooled to 0°C. Then, slowly add 500mL of concentrated sulfuric acid (H 2 SO 4 ). Thoroughly stir for 30 minutes while controlling the temperature of the reaction system not to exceed 5°C. Then add 3 g potassium permanganate (KMnO 4 ) into the three-necked flask, and stirred for 30 minutes while keeping the temperature of the reaction system not exceeding 10°C. Finally, 70g of potassium permanganate (KMnO 4 ) into the three-necked flask. Add in 4 batches within 1 hour while maintaining stirring, and the temperature of the reaction system does not exceed 20°C. It was then stirred at about 35°C for 2 hours to give a brown suspension. After 2 hours, 900 ml of deionized water was slowly added to the three-necked flask, and the temperature of the system rose rapidly to 90 °C, accompanied by a large amount of gas generatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com