Free radical-controllable RAFT soap-free emulsion polymerization method for hydroxy acrylic resin

A free radical hydroxyacrylic acid, soap-free emulsion polymerization technology, applied in the direction of coating, etc., can solve the problems of paint film adhesion, water resistance and gloss reduction, poor bonding force between resin and substrate, etc., and achieve a wide range of polymerization monomer adaptation Sexuality, easy synthesis, and the effect of preventing polymerization inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. "One-pot method" RFAT solution polymerization to prepare regular amphiphilic block copolymer macromolecular RAFT reagents:

[0038] The hydrophilic monomer is acrylic acid and hydroxyethyl methacrylate, the hydrophobic monomer is styrene, and the RAFT reagent is S-n-dodecyl-S'-(α,α'-dimethyl-α'' -Acetoxy)trithiocarbonate (DDMAT), the initiator is 4,4'-azobis(cyanovaleric acid) (V501), the solvent is 1,4-dioxane, and its composition formula is as follows :

[0039]

[0040] Concrete preparation process is as follows:

[0041] (1) Add 5.46 g of RAFT reagent DDMAT into a four-necked round bottom flask, stir and dissolve it in 184.26 g of 1,4-dioxane solvent, and inject N 2 Divide O 2 After 30 min, the temperature was raised to 80 °C; then 0.42 g of oil-soluble initiator V501 was fully dissolved in an appropriate amount of solvent, and then mixed with 21.6 g of acrylic acid and 65.07 g of hydroxyethyl methacrylate two hydrophilic unsaturated monomers in parallel A...

Embodiment 2

[0053] 1. "One-pot method" RFAT solution polymerization to prepare regular amphiphilic block copolymer macromolecular RAFT reagents:

[0054] The hydrophilic monomer is acrylic acid and hydroxyethyl methacrylate, the hydrophobic monomer is isooctyl methacrylate, and the RAFT reagent is S-n-dodecyl-S'-(α,α'-dimethyl -α''-acetoxy)trithiocarbonate (DDMAT), the initiator is 4,4'-azobis(cyanovaleric acid) (V501), the solvent is 1,4-dioxane, and The component formula is as follows:

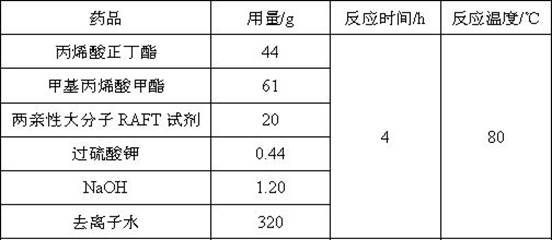

[0055]

[0056] Concrete preparation process is as follows:

[0057] (1) Add 5.46 g of RAFT reagent DDMAT into a four-necked round bottom flask, stir and dissolve it in 184.26 g of 1,4-dioxane solvent, and inject N 2 Divide O 2 After 30 min, the temperature was raised to 80 °C; then 0.42 g of oil-soluble initiator V501 was fully dissolved in an appropriate amount of solvent, and then mixed with 21.6 g of acrylic acid and 65.07 g of hydroxyethyl methacrylate two hydrophilic unsaturated monomers in ...

Embodiment 3

[0069] 1. "One-pot method" RFAT solution polymerization to prepare regular amphiphilic block copolymer macromolecular RAFT reagents:

[0070] The hydrophilic monomers are acrylic acid and hydroxyethyl methacrylate, and the RAFT reagent is S-n-dodecyl-S'-(α,α'-dimethyl-α''-acetoxy) trithiocarbonic acid Ester (DDMAT), the initiator is 4,4′-azobis(cyanovaleric acid) (V501), the solvent is 1,4-dioxane, and its composition formula is as follows:

[0071]

[0072] Concrete preparation process is as follows:

[0073] (1) Add 5.46 g of RAFT reagent DDMAT into a four-necked round bottom flask, stir and dissolve it in 184.26 g of 1,4-dioxane solvent, and inject N 2 Divide O 2 After 30 min, the temperature was raised to 80 °C; then 0.42 g of oil-soluble initiator V501 was fully dissolved in an appropriate amount of solvent, and then mixed with 21.6 g of acrylic acid and 40 g of hydroxyethyl methacrylate two hydrophilic unsaturated monomers in parallel Add it dropwise into a round b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com