Calendar adhesive

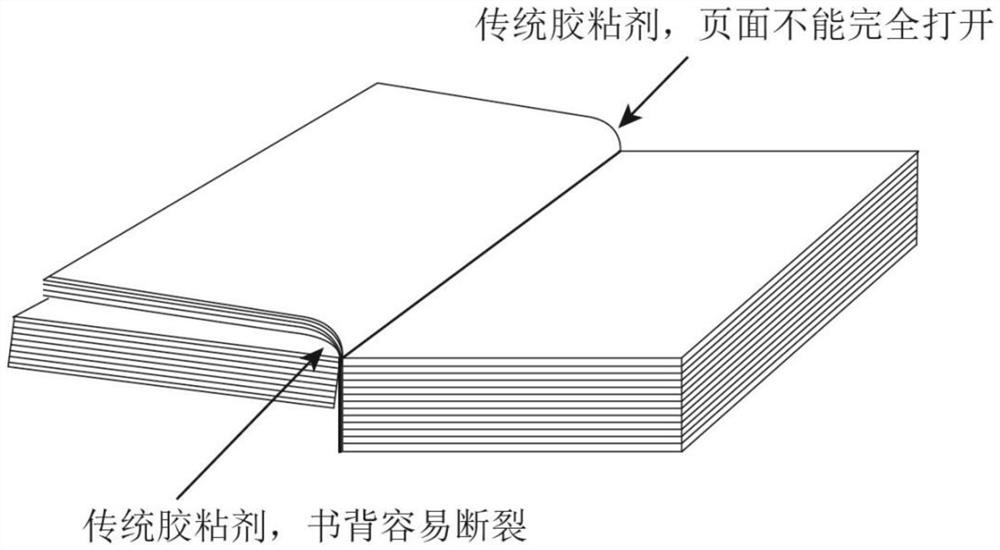

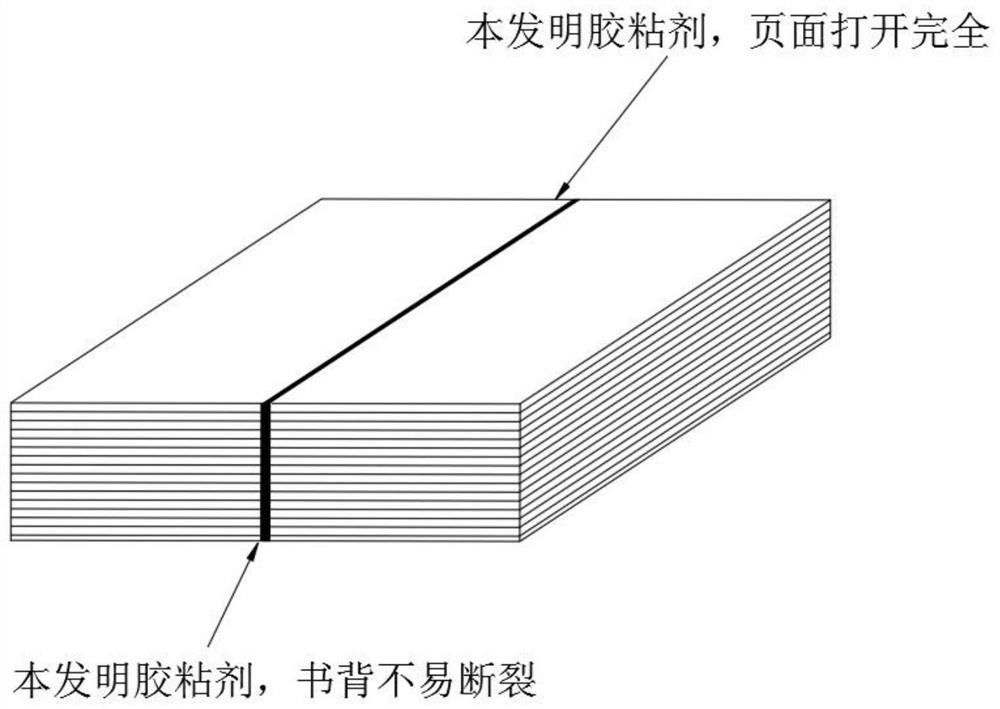

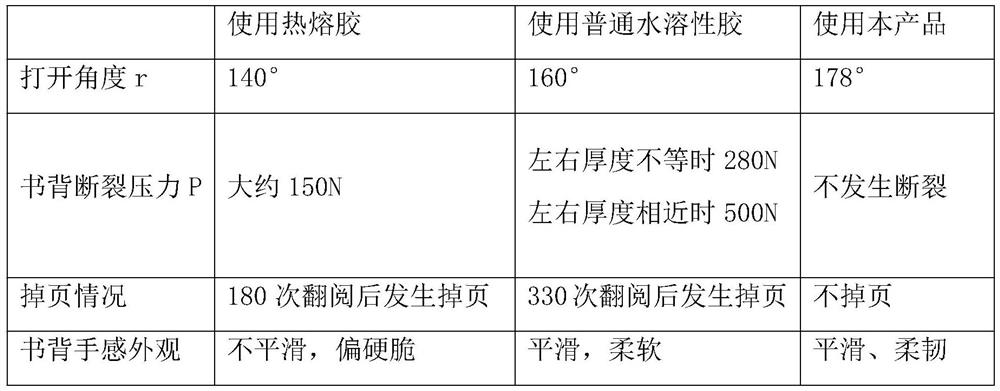

A technology for adhesives and calendars, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as insufficient bonding strength, large flipping angle, easy page drop, etc., to improve weather resistance and service life , Improve the flexibility of the film, and solve the effect that it is not easy to read

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] see Figure 1~2 , in the embodiment of the present invention, calendar adhesive, the preparation method of calendar adhesive is the following steps:

[0026] S1. Put a certain amount of antibacterial and antifungal agent, weather-resistant plasticizing composition, defoamer and emulsifier into the mixing tank, and stir evenly for 15-20min under the condition of 40-50°C to obtain the third component;

[0027] S2. Then put the first component and the second component into the mixing tank, mix evenly with the third component, and stir at a constant speed of 80-90r / min, control the temperature at 20-30°C, and control the stirring time at 20 -30min, after uniform mixing, the calendar adhesive can be prepared;

[0028] Among them, the pH value of the 320-type ternary copolymerization high-viscosity white glue is 6.5-7.5, and the 320-type terpolymerization high-viscosity white glue is passed through the NDJ rotational viscometer with the No. The viscosity measured under temp...

Embodiment 1

[0035] Calendar adhesive, the adhesive is composed of three components, the three components are divided into parts by weight:

[0036] The first component: 40 parts of 320-type ternary copolymer high-viscosity white glue;

[0037] The second component: 30 parts of 7013 latex;

[0038] The third component: 15 parts of antibacterial and antifungal agent, 5 parts of weather-resistant plasticizing composition, 3 parts of defoamer, and 7 parts of emulsifier;

[0039] The antibacterial and antifungal agent is composed of 25 parts by weight of nano-titanium dioxide, 35 parts of nano-zinc oxide and 40 parts of nano-silicon dioxide, and the proportion of nano-titanium dioxide, nano-zinc oxide and nano-silicon dioxide is: 0.25:0.35 :0.4;

[0040] The weather-resistant plasticizing composition is composed of 15 parts by weight of talcum powder, 10 parts of quartz powder, 20 parts of mica powder, 20 parts of amphibole asbestos powder, and the balance is water.

Embodiment 2

[0042] Calendar adhesive, the adhesive is composed of three components, the three components are divided into parts by weight:

[0043] The first component: 35 parts of 320-type ternary copolymer high-viscosity white glue;

[0044] The second component: 25 parts of 7013 latex;

[0045] The third component: 10 parts of antibacterial and antifungal agent, 15 parts of weather-resistant plasticizing composition, 5 parts of defoamer, and 10 parts of emulsifier;

[0046] The antibacterial and antifungal agent is composed of 30 parts by weight of nano-titanium dioxide, 40 parts of nano-zinc oxide and 50 parts of nano-silicon dioxide, and the proportion of nano-titanium dioxide, nano-zinc oxide and nano-silicon dioxide is: 0.25:0.35 :0.4;

[0047] The weather-resistant plasticizing composition is composed of 20 parts by weight of talcum powder, 15 parts of quartz powder, 30 parts of mica powder, 35 parts of amphibole asbestos powder, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com