Circulating fluidized bed pulverized coal pyrolysis-gasification device and pulverized coal pyrolysis-gasification method

A circulating fluidized bed and fluidized bed gasifier technology, applied in the field of coal gasification, can solve the problems of low utilization rate of pulverized coal, difficult utilization of low-rank coal, low carbon conversion rate and low gasification intensity, and achieve cost saving , reduce energy consumption, and expand the scope of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

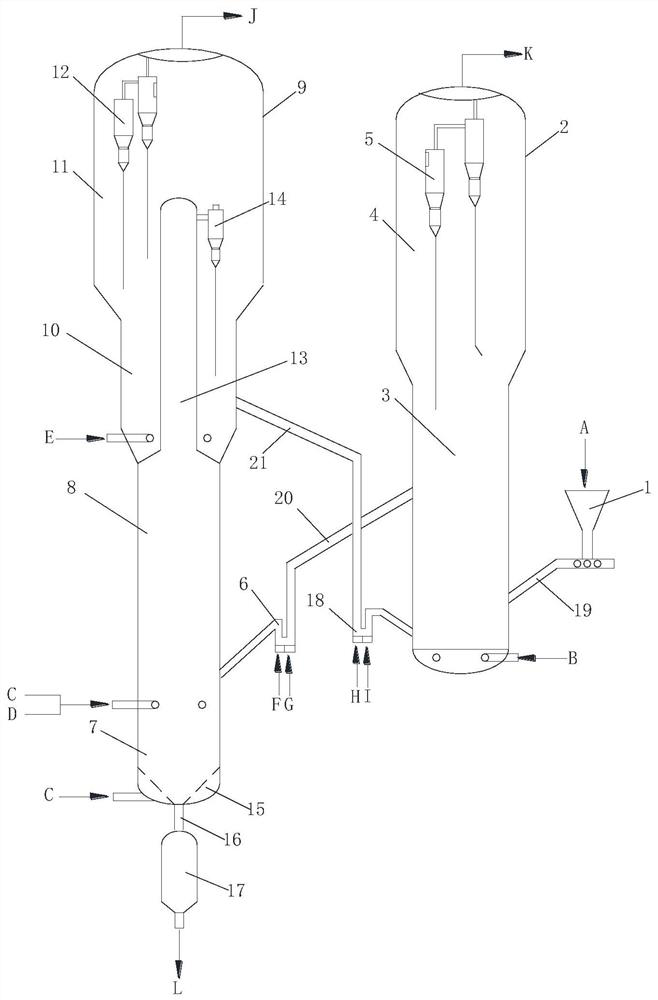

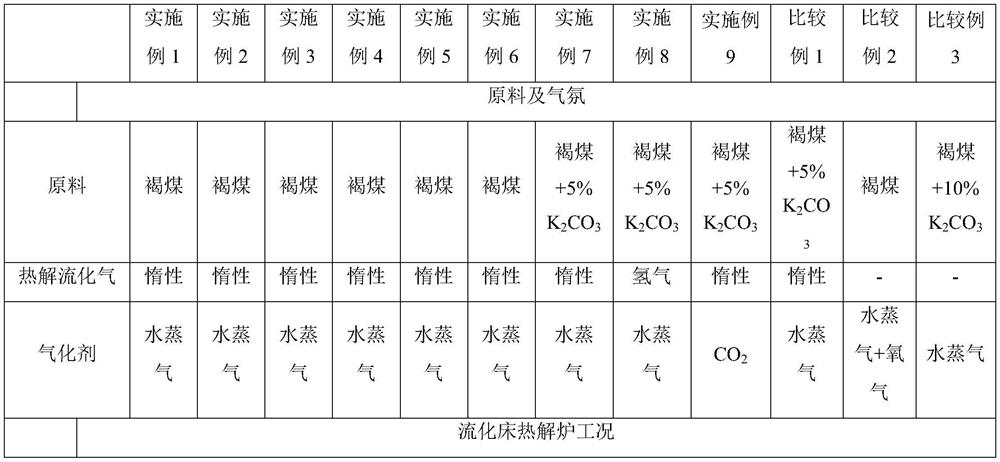

[0070] The reaction process is as follows: the pulverized coal raw material is sent from the feeder (1) to the dense-phase area (3), mixed with high-temperature gasified semi-coke and heated, and a pyrolysis reaction occurs, and the pyrolysis gas entrained with fine coal powder is separated by gas-solid separation The recovered fine coal powder returns to the dense-phase area (3), and the pyrolysis semi-coke enters the lower part of the fluidized bed gasifier (8) after the circulation amount is controlled by the pyrolysis semi-coke return valve (6). Pyrolysis semi-coke is contacted with gasification agent D, and gasification reaction occurs in fluidized bed gasifier (8) and fast bed gasifier (13) to generate synthesis gas, which passes through cyclone separator (14) of fast bed gasifier After separating the gasified semi-coke that has not been gasified, it enters the upper settling section (11) of the fine powder sedimentation / stripping device (9), and the gasified semi-coke th...

Embodiment 2

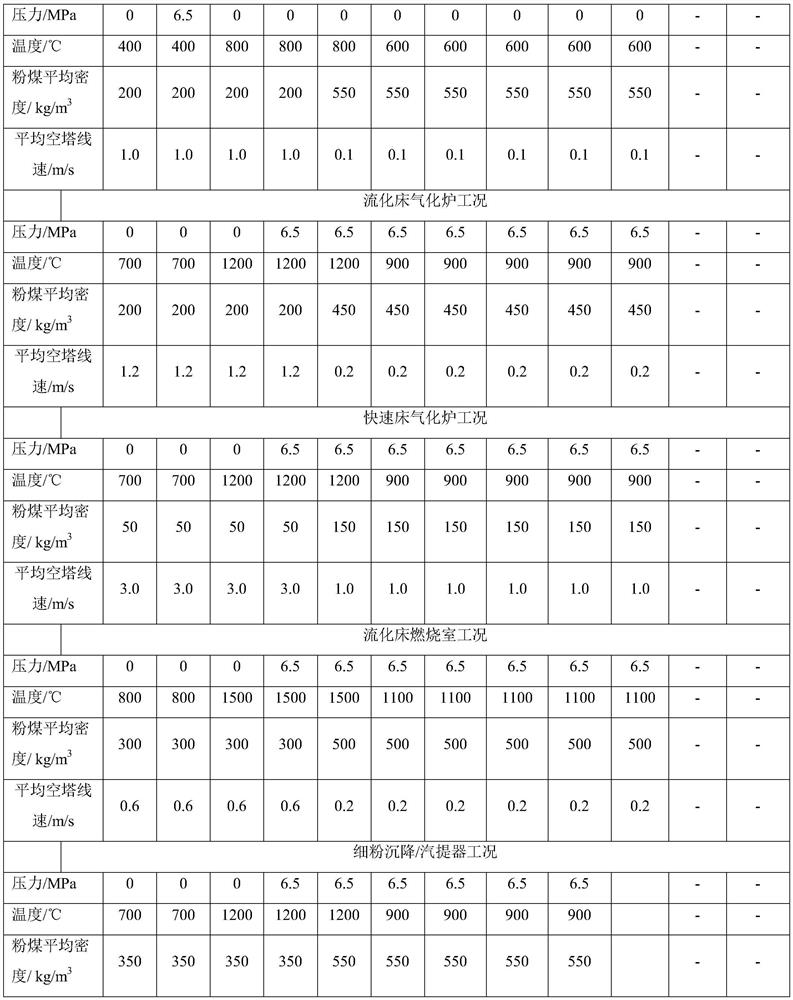

[0073] The reaction process is the same as in Example 1. In the reaction process, the pulverized coal raw material is lignite, the pyrolysis pressure of the fluidized bed pyrolysis furnace (2) is 6.5MPa, and the pyrolysis temperature is 400°C. Coal average density 200kg / m 3 , fluidized bed pyrolysis furnace (2) reactor dense phase zone (3) inner superficial linear velocity 1.0m / s; fluidized bed gasification furnace (8) gasification pressure 0MPa, gasification temperature 700 ℃, powder Coal average density 200kg / m 3 , the average superficial velocity in the fluidized bed gasifier (8) is 1.2m / s; the gasification pressure of the fast bed gasifier (13) is 0MPa, the gasification temperature is 700°C, and the average density of pulverized coal is 50kg / m 3 ; The average superficial linear velocity in the fast bed gasifier (13) is 3.0m / s, the combustion pressure of the fluidized bed combustion chamber (7) is 0MPa, the combustion temperature is 800°C, and the average density of pulve...

Embodiment 3

[0075] The reaction process is the same as in Example 1. In the reaction process, the pulverized coal raw material is lignite, the pyrolysis pressure of the fluidized bed pyrolysis furnace (2) is 0, and the pyrolysis temperature is 800°C. The pulverized coal in the dense phase zone of the fluidized bed pyrolysis furnace (2) reactor (3) Average density 200kg / m 3 , fluidized bed pyrolysis furnace (2) reactor dense phase zone (3) inner superficial linear velocity 1.0m / s; fluidized bed gasification furnace (8) gasification pressure 0, gasification temperature 1200 ℃, powder Coal average density 200kg / m 3 , the average superficial velocity in the fluidized bed gasifier (8) is 1.2m / s; the gasification pressure of the fast bed gasifier (13) is 0, the gasification temperature is 1200°C, and the average density of pulverized coal is 50kg / m 3 ; The average superficial velocity in the fast bed gasifier (13) is 3.0m / s, the combustion pressure of the fluidized bed combustion chamber (7) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com