Degradable antibacterial composite non-woven fabric and application thereof

A non-woven fabric and multi-purpose technology, applied in the direction of non-woven fabrics, textiles and papermaking, anti-coloring pollution/anti-fouling fibers, etc., can solve the problems of non-compliance with environmental protection requirements, poor wear resistance, poor antibacterial effect, etc., to achieve Improve long-term antibacterial effect, improve mechanical properties, and enhance air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of modified jute fiber is specifically:

[0035] (1) According to the mass ratio of 1:1.5, dissolve the extract of Acanthopanax in 80% ethanol, add diatomaceous earth in proportion, dry it after fully stirring, dry it under reduced pressure to constant weight, and grind it into nanoparticles; 90nm.

[0036] (2) take jute fiber pulp as raw material, utilize conventional viscose process to make viscose collagen solution, add the described nano-particles that account for hemp fiber content 16% in the viscose collagen solution step, then prepare through known viscose glue such as mixing The blended spinning solution is prepared by the process, and then spun through a coagulation bath, and the as-spun tow is drawn to obtain a shaped tow, and the obtained tow is cut, desulfurized, bleached, oil bathed, and dried to obtain Modified jute fiber. Among them, the coagulation bath includes sulfuric acid 75g / L, zinc sulfate 6.8g / L, sodium sulfate 320g / L; des...

Embodiment 2

[0041]The preparation of modified jute fiber is identical with embodiment 1.

[0042] A degradable antibacterial composite non-woven fabric, the components include: by weight, 22 parts of modified jute fibers, 22 parts of green sandalwood bark fibers, and 12 parts of grass coral fibers.

[0043] The difference between the preparation of the non-woven fabric and that of Example 1 is that the number of laying layers is set to 20, the needle-punching frequency is 436 r / min, and the thickness of the needle-punched non-woven fabric obtained is 2.9 mm.

Embodiment 3

[0045] The preparation of modified jute fiber is identical with embodiment 1.

[0046] A degradable antibacterial composite non-woven fabric, the components include: by weight, 24 parts of modified jute fiber, 18 parts of green sandalwood bark fiber, and 10 parts of grass coral fiber.

[0047] The difference between the preparation of the non-woven fabric and that of Example 1 is that the number of laying layers is set to 24, the needle-punching frequency is 445 r / min, and the thickness of the needle-punched non-woven fabric obtained is 4.2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

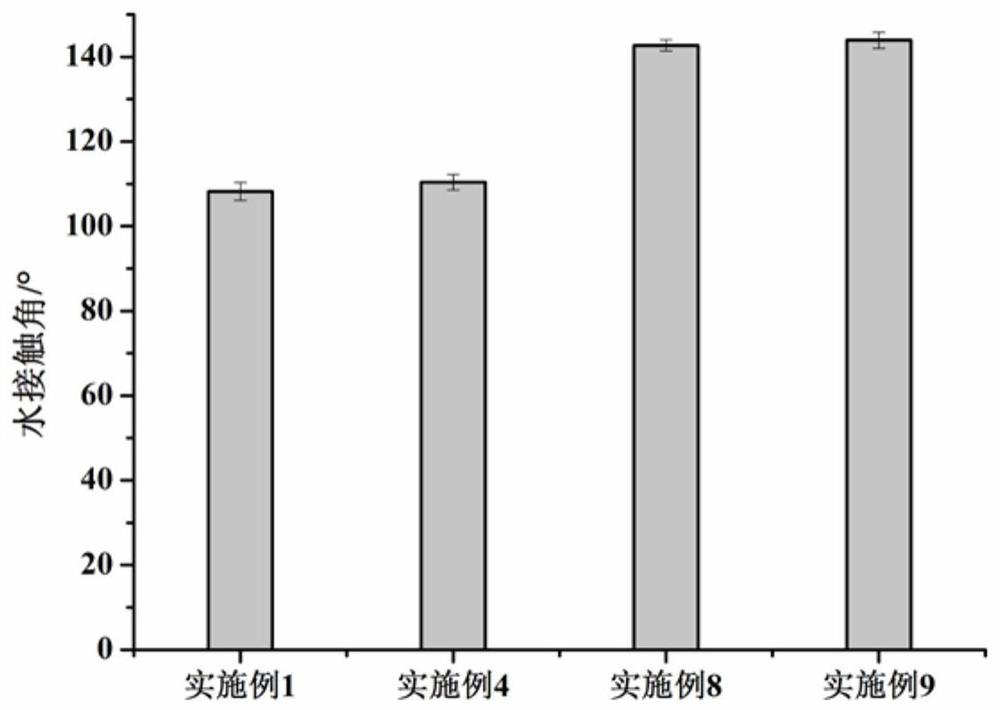

| Water contact angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com