A three-stream spiral wound printed circuit board heat exchanger core

A printed circuit board, spiral winding technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of insufficient compact structure, insufficient heat exchanger core strength, and reduced heat exchange efficiency. Achieve the effect of reducing pumping cost, reducing pressure loss and improving heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

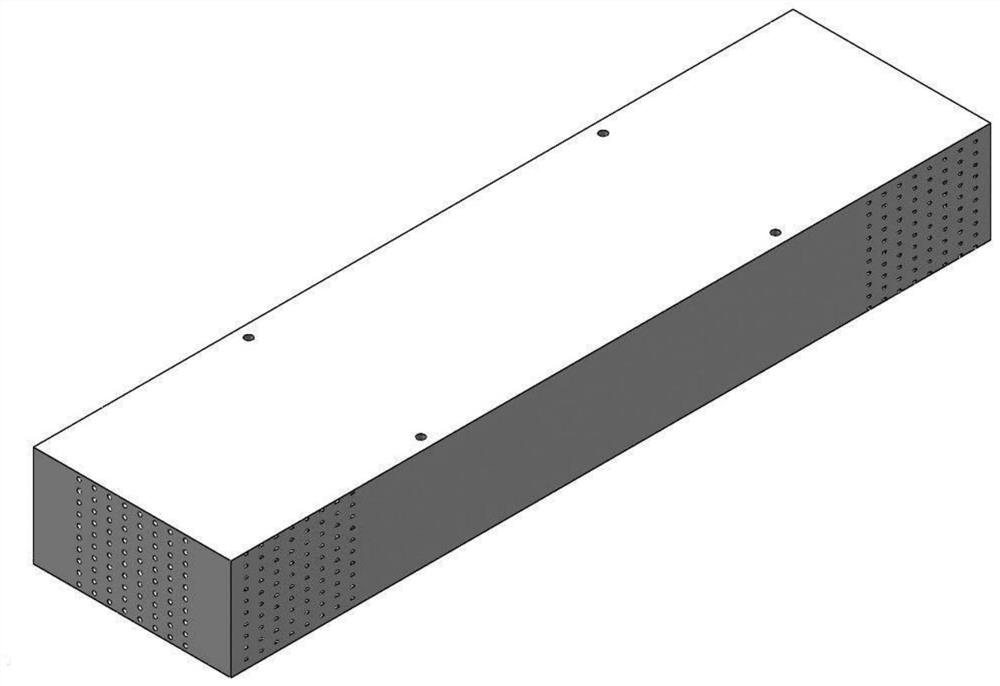

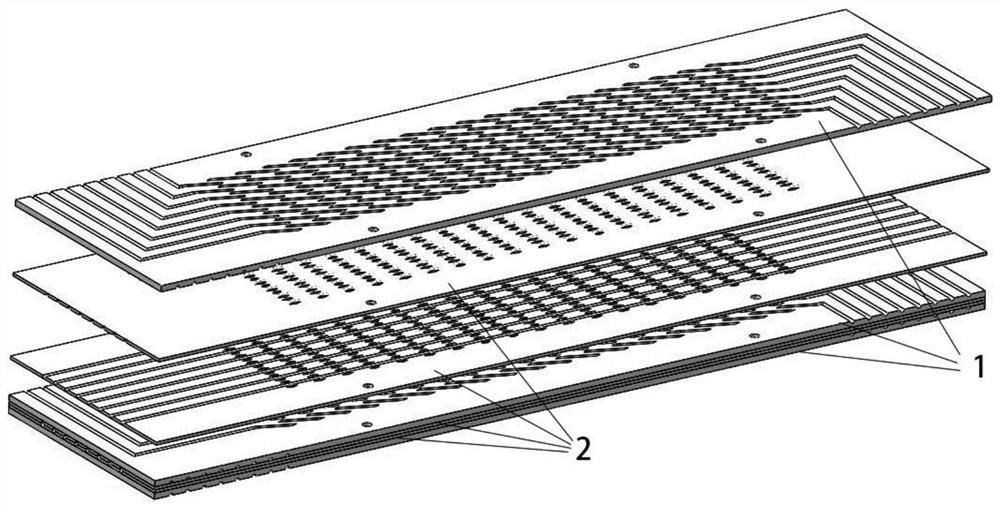

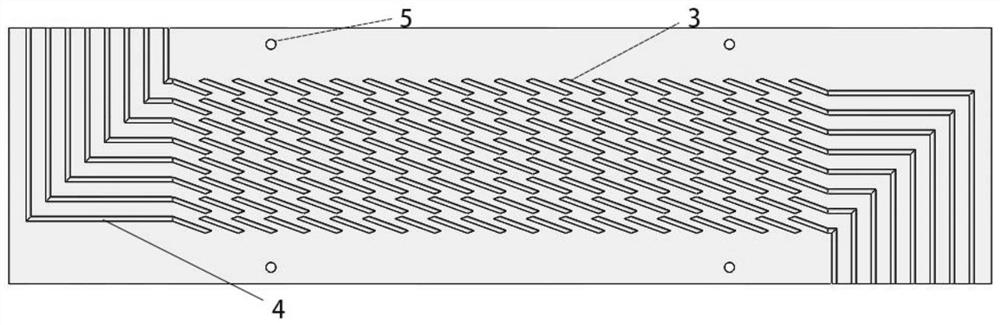

[0053] Such as Figure 1-7 As shown, a three-flow spirally wound printed circuit board heat exchanger core includes: several heat exchanger core units that are alternately stacked from top to bottom and welded into one body by vacuum diffusion welding technology. The heat exchanger core unit is composed of a double-sided etched flow channel plate 1, a perforated single-sided etched plate 2, and an inverted perforated single-sided etched plate 2, which are sequentially superimposed and welded to realize simultaneous heat exchange of two or three fluids. Wherein, the material of the double-sided etched channel plate 1 and the perforated single-sided etched plate 2 is stainless steel, copper alloy, aluminum alloy, titanium alloy or nickel-based alloy. And the double-sided etched flow channel plate 1 and the perforated single-sided etched plate 2 are provided with a number of coaxial symmetrical positioning holes 5, wherein at least two symmetrical positioning holes 5 are arranged...

Embodiment 2

[0065] Such as Figure 5 and Figure 6 As shown, different from Embodiment 1, in this embodiment, the cross-sectional shape of the flow path 6 is a semicircle, and the opposite two flow paths on the perforated single-sided etched plate 2 and the inverted perforated single-sided etched plate 2 The channels 6 are stacked to form a cylindrical flow channel.

[0066] In this example, if image 3 and Figure 4 As shown, the etched cross-sectional shape of the discontinuous channel 3 is a semicircle, which is obtained by photochemical etching. The diversion flow channel 4 is L-shaped bending shape, the opening of the bending part I on one side is opened on the side wall surface of the double-sided etched flow channel plate 1, and the end of the bending part II on the other side is connected with the discontinuous flow channel 3 Pass; the openings of the bending part I of the guide flow channel 4 on both sides of the double-sided etching flow channel plate 1 are set on the symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com