Sulfur-tolerant carbon dioxide methanation catalyst and preparation method thereof

A technology of methanation catalyst and carbon dioxide, which is applied in the field of catalysis, can solve the problems of complex preparation process of sol-gel method, high water consumption and energy consumption, no mention of sulfur resistance, etc., and achieve good sulfur resistance methanation performance, stable The effect of good performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

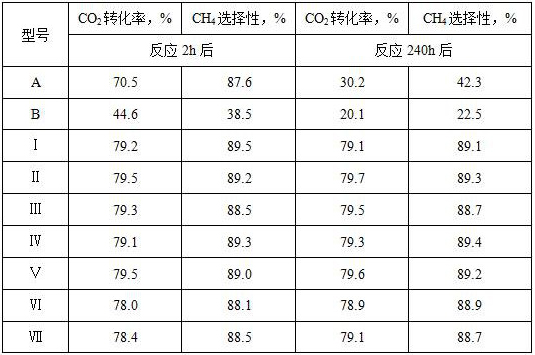

Examples

Embodiment 1

[0025] will contain Al(NO 3 ) 3 , Cu(NO 3 ) 2 The mixed solution and Na 2 CO 3 The solution was added to water concurrently, stirred and maintained for 1~2h. Add RhCl to the above solution 3 solution, add Na 2 CO 3 Solution, maintain the pH of the solution = 7~8, continue to stir and maintain for 1~2h. Add BiCl to the above solution 3 solution, add Na 2 CO 3 Solution, maintain the pH of the solution = 7~8, continue to stir and maintain for 1~2h. The molar ratio of the constituent elements of the catalyst is Al:Cu:Rh:Bi=10:0.5:0.01:0.01. After the precipitation, it was aged for 2 hours, washed, filtered, dried at 90°C for 12 hours, calcined at 350°C for 1 hour, and then pelletized to obtain catalyst I.

Embodiment 2

[0027] will contain Al(NO 3 ) 3 , Cu(NO 3 ) 2 The mixed solution and Na 2 CO 3 The solution was added to water concurrently, stirred and maintained for 1~2h. Add RhCl to the above solution 3 solution, add Na 2 CO 3 Solution, maintain the pH of the solution = 7~8, continue to stir and maintain for 1~2h. Add BiCl to the above solution 3 solution, add Na 2 CO 3 Solution, maintain the pH of the solution = 7~8, continue to stir and maintain for 1~2h. The molar ratio of the constituent elements of the catalyst is Al:Cu:Rh:Bi=10:3:0.3:0.2. After the precipitation, it was aged for 2 hours, washed, filtered, dried at 120°C for 24 hours, calcined at 700°C for 6 hours, and then pelletized to obtain catalyst II.

Embodiment 3

[0029] will contain Al(NO 3 ) 3 , Cu(NO 3 ) 2 The mixed solution and Na 2 CO 3 The solution was added to water concurrently, stirred and maintained for 1~2h. Add RhCl to the above solution 3 solution, add Na 2 CO 3 Solution, maintain the pH of the solution = 7~8, continue to stir and maintain for 1~2h. Add BiCl to the above solution 3 solution, add Na 2 CO 3 Solution, maintain the pH of the solution = 7~8, continue to stir and maintain for 1~2h. The molar ratio of the constituent elements of the catalyst is Al:Cu:Rh:Bi=10:0.5:0.1:0.1. After the precipitation, it was aged for 4 hours, washed, filtered, dried at 100°C for 18 hours, calcined at 550°C for 4 hours, and then pelletized to obtain catalyst III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com