A method for manufacturing modified expansion vitrified microbead anti-shrinkage compensation concrete

A technology of expanded vitrified microbeads and a manufacturing method, applied in the field of concrete, can solve the problems of increased slump of mixture, poor workability, unguaranteed thermal insulation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

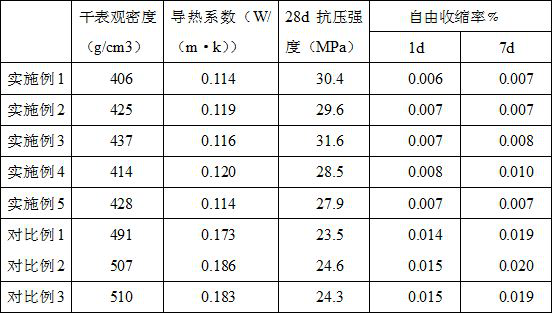

Examples

Embodiment 1

[0025] A modified expanded vitrified microsphere anti-shrinkage compensation concrete and a manufacturing method thereof, comprising the following steps:

[0026] (1) Add the expanded vitrified microbeads to the dimethylacetamide solution, slowly raise the temperature to 50°C and stir, keep the temperature and stir for 10 minutes, then add a pH adjuster dropwise to maintain the pH at 8, and continue stirring for 5 minutes; Take out and cool and dry naturally, add silica sol and N-methylmorpholine dropwise to the dried expanded vitrified microbeads simultaneously, the dropping rate of silica sol is 6ml / min, and the dropping rate of N-methylmorpholine 3ml / min. Stir the expanded vitrified microbeads while adding dropwise. The mass ratio of the silica sol to the dried expanded vitrified microbeads is 0.1:1. The mass ratio of vitrified microbeads is 0.07:1. After the dropwise addition, continue to stir and raise the temperature to 80 °C, keep the temperature for 20 minutes, dispers...

Embodiment 2

[0031] A modified expanded vitrified microsphere anti-shrinkage compensation concrete and a manufacturing method thereof, comprising the following steps:

[0032](1) Add the expanded vitrified microbeads to the dimethylacetamide solution, slowly heat up to 55°C and stir, keep the temperature and stir for 15 minutes, then add a pH adjuster dropwise to maintain the pH at 9, and continue to stir for 10 minutes; Take out and cool and dry naturally, add silica sol and N-methylmorpholine dropwise to the dried expanded vitrified microbeads at the same time, the drop rate of silica sol is 9ml / min, and the drop rate of N-methylmorpholine 5ml / min, while stirring the expanded vitrified microbeads while adding dropwise, the mass ratio of silica sol to the dried expanded vitrified microbeads is 0.3:1, N-methylmorpholine and the dried expanded glass The mass ratio of vitrified microbeads is 0.07:1. After the dropwise addition, continue to stir and raise the temperature to 90 °C, keep the te...

Embodiment 3

[0037] A modified expanded vitrified microsphere anti-shrinkage compensation concrete and a manufacturing method thereof, comprising the following steps:

[0038] (1) Add the expanded vitrified microbeads to the dimethylacetamide solution, slowly heat up to 60°C and stir, keep the temperature and stir for 20 minutes, then add a pH adjuster dropwise to maintain the pH at 8, and continue stirring for 5 minutes; Take out and cool and dry naturally, add silica sol and N-methylmorpholine dropwise to the dried expanded vitrified microbeads at the same time, the drop rate of silica sol is 8ml / min, and the drop rate of N-methylmorpholine At 5ml / min, the expanded vitrified microbeads were stirred while adding dropwise. The mass ratio of the silica sol to the dried expanded vitrified microbeads was 0.15:1. The mass ratio of vitrified microbeads is 0.06:1. After the dropwise addition, continue to stir and raise the temperature to 90 °C, keep warm for 20 minutes, disperse the expanded vit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com