Composite calcium-silicon organic fertilizer, raw material formula and preparation method

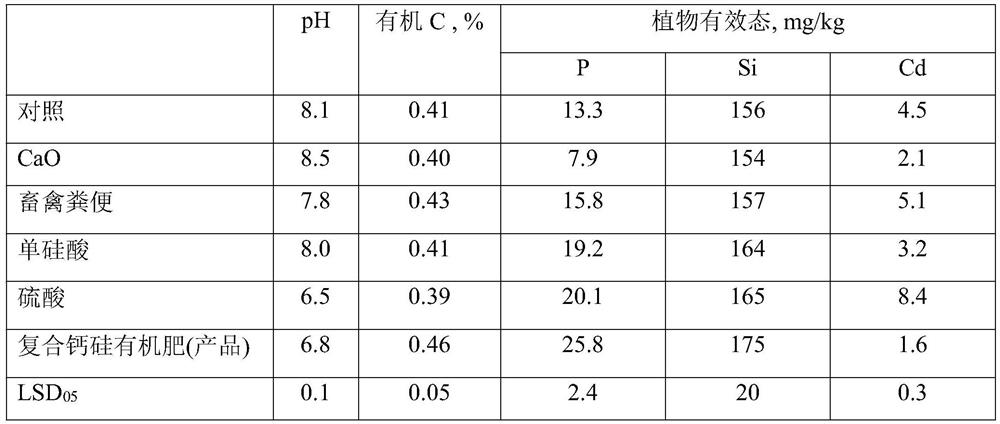

An organic fertilizer and calcium-silicon technology, which is applied in the field of raw material formula, preparation, and compound calcium-silicon organic fertilizer, can solve problems such as no good solutions, and achieve the effects of reducing heavy metal activity, increasing plant available phosphorus, and providing silicon nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

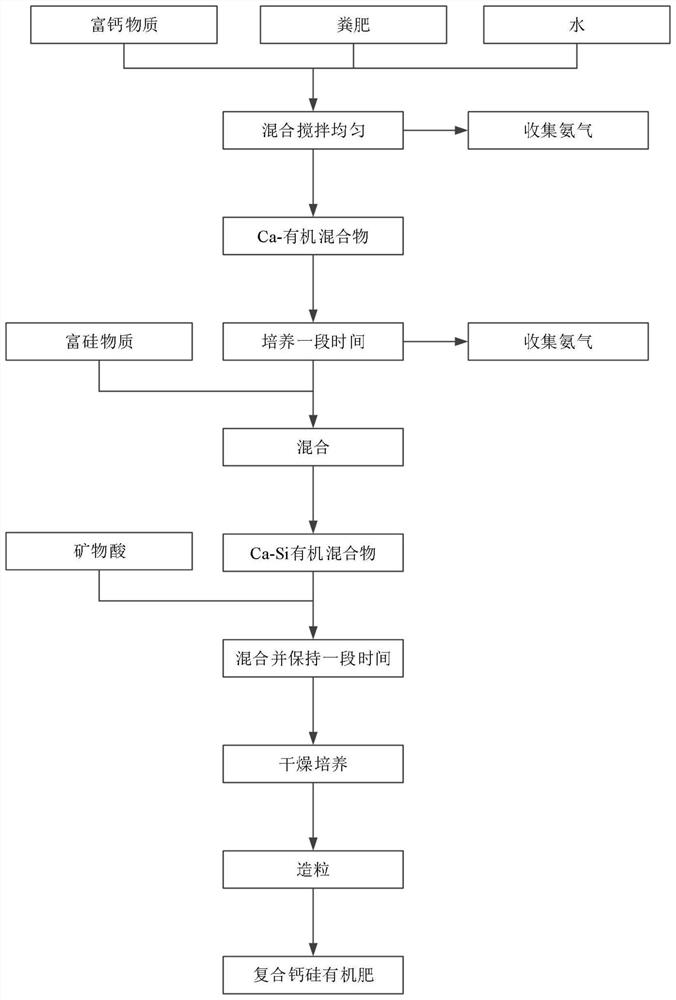

[0024] See figure 1 , the present invention provides a kind of preparation method of composite calcium-silicon organic fertilizer, comprising: mixing and stirring calcium-rich material, manure, and water evenly to form a Ca-organic mixture; collecting ammonia; cultivating the Ca-organic mixture for a period of time and The silicon-rich substances are mixed to obtain a Ca-Si organic mixture; the Ca-Si organic mixture is mixed with mineral acid and kept for a period of time; dried and cultivated; and granulated to obtain the composite calcium-silicon organic fertilizer.

[0025] Specifically, the calcium-rich substance is mixed with animal or / and poultry manure for 10 minutes to 1 hour, and the water content of the original mixture is 40-60%; the ammonia is captured with water from the beginning of the mixing process, and lasts for 5-10 hours; The Ca-organic mixture was incubated for 10-100 hours following the stirring process; ammonia gas was collected from the mixed gas. Mix ...

Embodiment 1

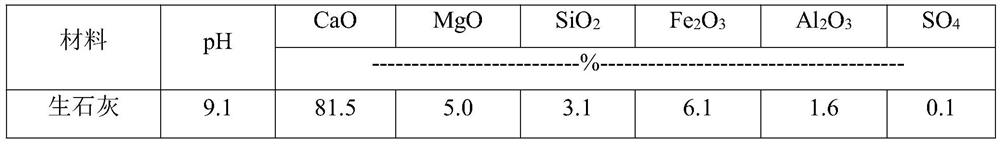

[0041] Take quicklime, poultry manure and mix for 10 minutes to ensure that the water content of the original mixture is 40%; capture ammonia with water from the beginning of the mixing process and continue for 5 hours; maintain the Ca-organic mixture for 10 hours after the mixing process; in 10 minutes Mix the Ca-organic mixture with a liquid silicon-containing solution with a Si content of 10 mg / liter to obtain a Ca-Si-organic mixture; mix the resulting Ca-Si-organic mixture with phosphoric acid for 1 to 60 minutes, and then keep it for 1 ~ 10 days, drying the culture mixture until the moisture content is 1%, and granulating to obtain a compound calcium-silicon organic fertilizer. Wherein the mass ratio of calcium-rich substance to poultry manure is 1:3, and the volume ratio of the Ca-Si organic mixture to phosphoric acid is 1:100.

Embodiment 2

[0043] Mix calcium-rich substances and animal manure for 1 hour, and ensure that the water content of the original mixture is 60%; maintain the Ca-organic mixture for 100 hours after the stirring process, and capture ammonia with water at the same time, and continue for 10 hours; Mix the Ca-organic mixture with a liquid silicon-containing solution with a Si content of 50,000 mg / L within 1 hour to obtain a Ca-Si-organic mixture; mix the resulting Ca-Si-organic mixture with nitric acid for 1 to 60 minutes, and then keep 1 to 10 days, drying the culture mixture until the water content is 1%; granulating to obtain the compound calcium-silicon organic fertilizer. Wherein the mass ratio of calcium-rich substance to animal feces is 1:3, and the volume ratio of the Ca-Si organic mixture to nitric acid is 10:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com