Light orange refrigeration coating with double-layer structure as well as preparation method and application thereof

A double-layer structure, orange technology, applied in luminescent coatings, reflective/signal coatings, coatings, etc., can solve the problems of complex preparation of passive refrigeration coatings, high preparation costs, poor refrigeration effect, etc., and achieve significant cooling effect and energy saving. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of white fluorescent and radiant refrigeration primer: mix hydrophobic styrene-acrylic emulsion, sky blue luminous pigment, calcium stearate, talcum powder, titanium dioxide, polycarboxylate ammonium salt dispersant, nonylphenol polyoxyethylene ether wetting agent, polyether After the defoamer and water are mixed, stir and disperse at a high speed of 1000 rpm for 100 minutes, and add urethane thickening and leveling agent and ester film-forming aid to the solution after stirring and dispersing, and disperse evenly;

[0036]Preparation of light orange topcoat: styrene-acrylic emulsion, titanium dioxide, photoluminescence pigment, near-infrared transmission orange pigment, polycarboxylate ammonium salt dispersant, nonylphenol polyoxyethylene ether wetting agent, polyether defoamer After mixing with water, stir and disperse at a high speed of 900 rpm for 30 minutes, press the dispersed mixture into a grinding jar for grinding for 30 minutes, add polyurethane thi...

Embodiment 1-3

[0037] The concrete detection method of embodiment 1-3 is as follows:

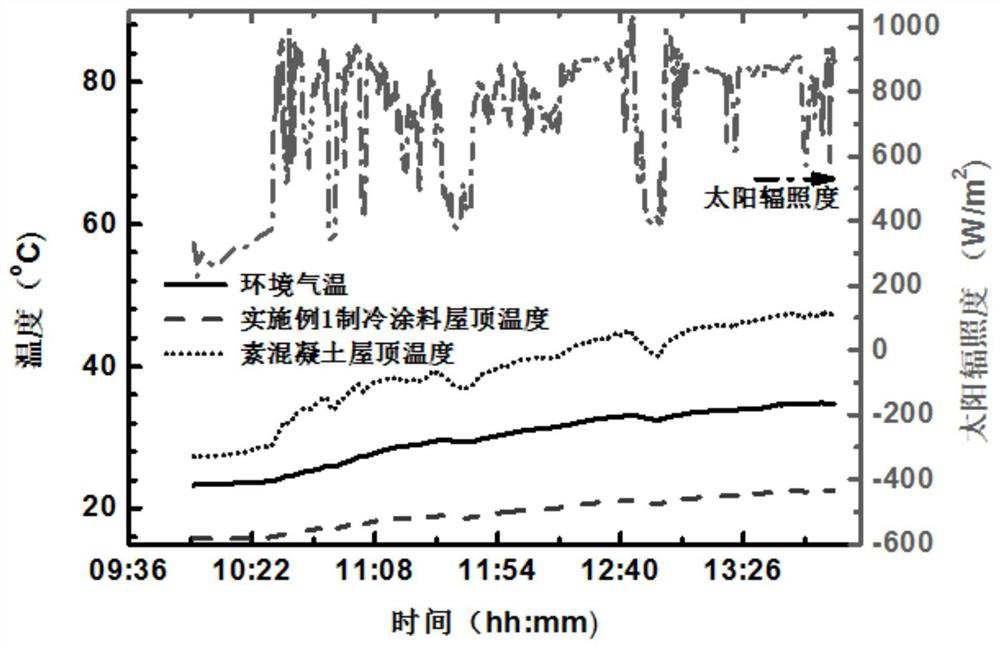

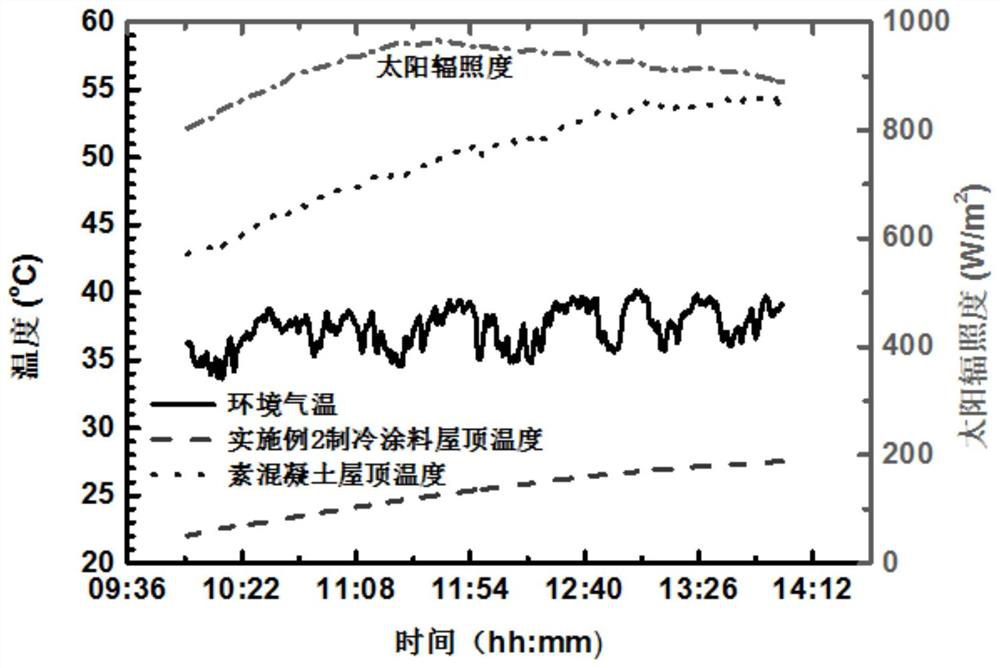

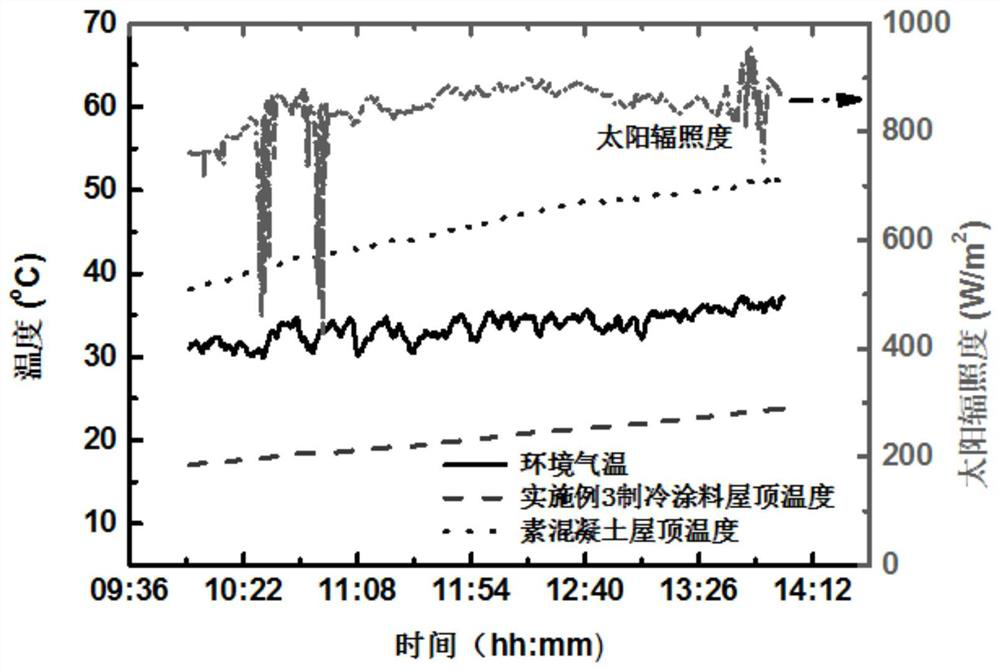

[0038] The prepared white fluorescent and radiant cooling primer and light orange topcoat were coated by roller coating on the roof and wall of a model house of 2 meters long x 2 meters wide x 2.2 meters high built in precast concrete for outdoor experiments . Among them, the dry film thickness of the white fluorescent and radiant cooling primer is greater than or equal to 300 microns, and the dry film thickness of the light orange topcoat is less than or equal to 50 microns.

[0039] When measuring the cooling effect, the thermal resistance for measuring the roof surface temperature is installed in the center of the roof surface, the upper surface of the temperature measuring element is flush with the roof surface, and then the primer and finish paint are applied. The thermal resistor for measuring the indoor temperature is hung in the center of the house, and the thermal resistor for measuring the ambie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap