High-frequency soft magnetic material and preparation method thereof

A soft magnetic material, high frequency technology, applied in the direction of magnetic materials, metal material coating process, magnetic objects, etc., can solve the application requirements in the high frequency field, the weakening of soft magnetic properties and high frequency characteristics, low coercivity and other problems, to achieve the effect of excellent soft magnetic performance, saving production cost and time, and low damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

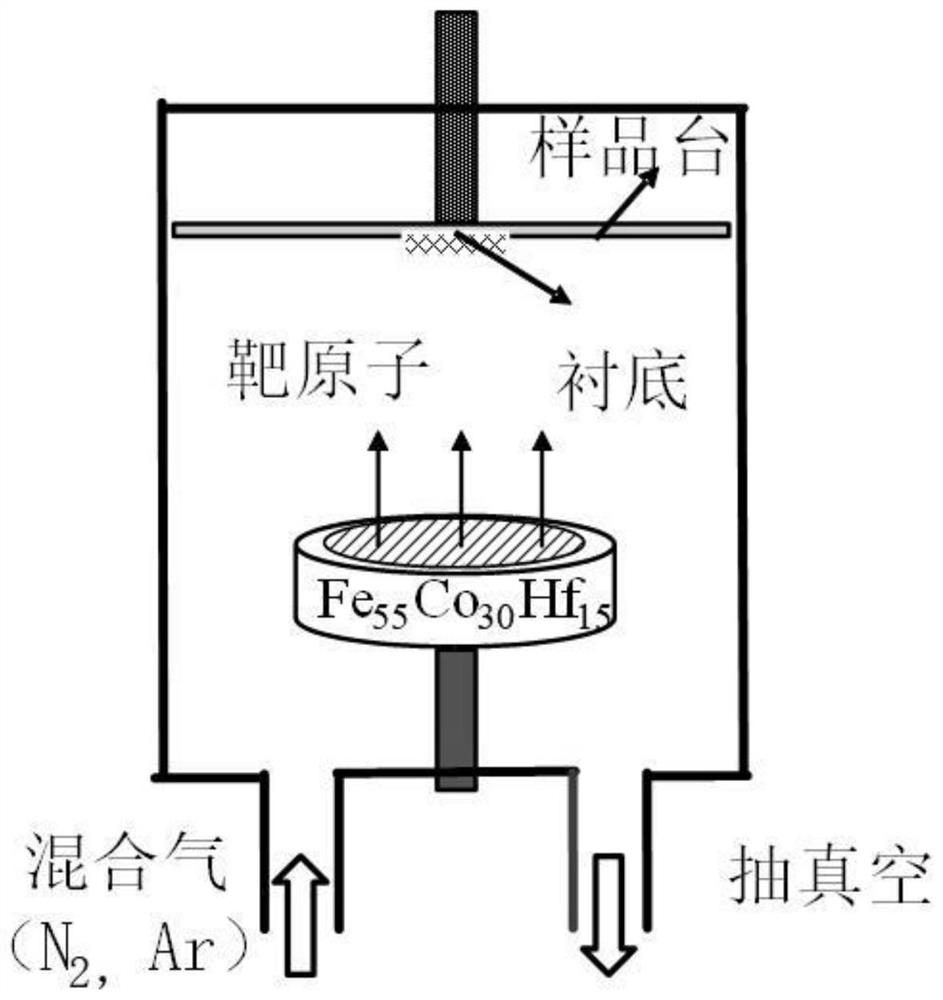

[0047] A high-frequency soft magnetic material with a chemical formula of Fe 55 co 27 f 5 N 13 , which is prepared as figure 1 As shown, the specific steps are as follows:

[0048] (1) Prepare Fe with a purity of 99.95% 55 co 30 f 15 Alloy targets, Si(100) substrates are cut as needed, and the silicon wafer substrates are cleaned by RCA semiconductor silicon wafer cleaning process, and dried with nitrogen gas for later use;

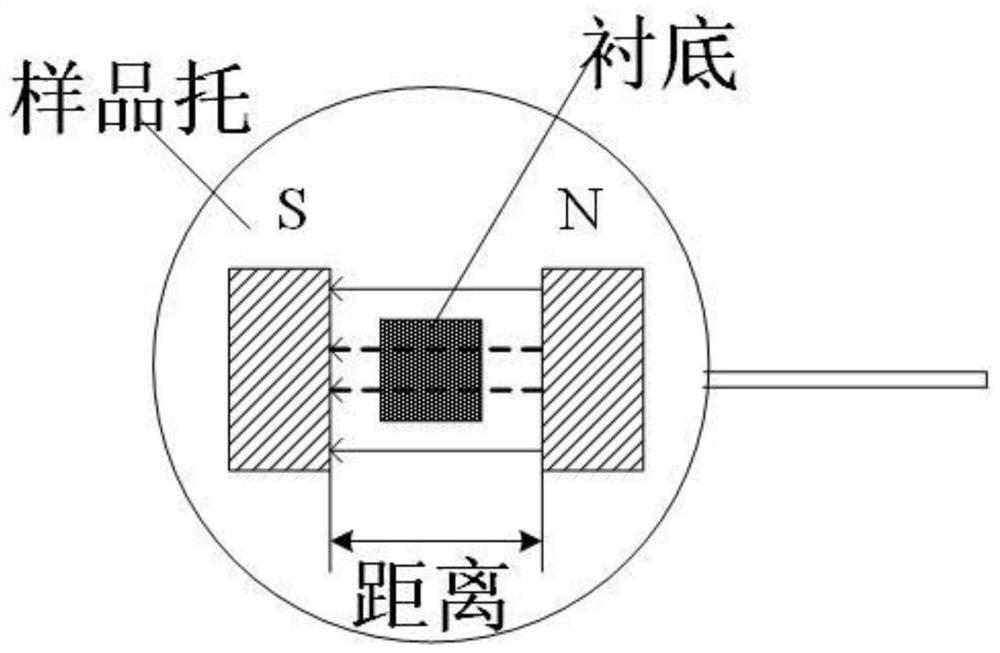

[0049] (2) if figure 2 Shown is a schematic diagram of in-situ application of a magnetic field to a high-frequency soft magnetic material. First, a NdFeB permanent magnet of a specific size is processed by wire cutting and fixed on the sample holder. The distance between the two permanent magnets is 10mm, and the substrate is located in the space of the permanent magnet. At the very center, the direction of the induced field is parallel to the surface of the substrate, and the size of the induced field is 500Oe. Then place the substrate holder o...

Embodiment 2

[0057] A high-frequency soft magnetic material with a chemical formula of Fe 53 co 33 h 5 N 9 , which is prepared as figure 1 As shown, the specific steps are as follows:

[0058] (1) Prepare Fe with a purity of 99.95% 55 co 30 f 15 Alloy targets, Si(100) substrates are cut as needed, silicon wafers are cleaned by RCA semiconductor silicon wafer cleaning process, and dried with nitrogen gas for later use;

[0059] (2) if figure 2 Shown is a schematic diagram of in-situ application of a magnetic field to a high-frequency soft magnetic material. First, a NdFeB permanent magnet of a specific size is processed by wire cutting and fixed on the sample holder. The distance between the two permanent magnets is 25mm, and the substrate is located in the space of the permanent magnet. At the very center, the direction of the induced field is parallel to the surface of the substrate, and the size of the induced field is 70Oe. Then place the sample holder on the sample stage, clo...

Embodiment 3

[0063] A high-frequency soft magnetic material with a chemical formula of Fe 47 co 33 f 9 N 11 , which is prepared as figure 1 As shown, the specific steps are as follows:

[0064] (1) Prepare Fe with a purity of 99.95% 55 co 30 f 15 Alloy targets, Si(100) substrates are cut as needed, silicon wafers are cleaned by RCA semiconductor silicon wafer cleaning process, and dried with nitrogen gas for later use;

[0065] (2) if figure 2 Shown is a schematic diagram of in-situ application of a magnetic field to a high-frequency soft magnetic material. First, a NdFeB permanent magnet of a specific size is processed by wire cutting and fixed on the sample holder. The distance between the two permanent magnets is 10mm, and the substrate is located in the space of the permanent magnet. At the very center, the direction of the induced field is parallel to the surface of the substrate, and the size of the induced field is 500Oe. Then place the sample holder on the sample stage, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resonance frequency | aaaaa | aaaaa |

| Resonance frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com