Blood orange exosome microcapsule embedded freeze-dried powder and preparation method thereof

A technology of exosomes and freeze-dried powder, applied in the biological field, can solve the problems of easy clustering, easy rupture and uneven particle size of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a plant exosome microencapsulated freeze-dried powder, including plant exosomes, a primary coating and a secondary coating; the primary coating is wrapped on the surface of the plant exosomes, and the The secondary coating is wrapped on the surface of the primary coating; the components of the primary coating are selected from alginate; the components of the secondary coating are selected from animal cellulose.

[0037] In some embodiments, the alginate is selected from sodium alginate or calcium alginate; the animal cellulose is selected from chitosan oligosaccharide.

[0038] In some embodiments, the plant exosome microencapsulated lyophilized powder also contains a lyoprotectant; the lyoprotectant is selected from resistant dextrins.

[0039]In some embodiments, the plant exosomes are selected from ginger exosomes, garlic exosomes, scallion exosomes, onion exosomes, grapefruit exosomes, broccoli exosomes, cucumber exosomes , turmeric exosome...

Embodiment 2

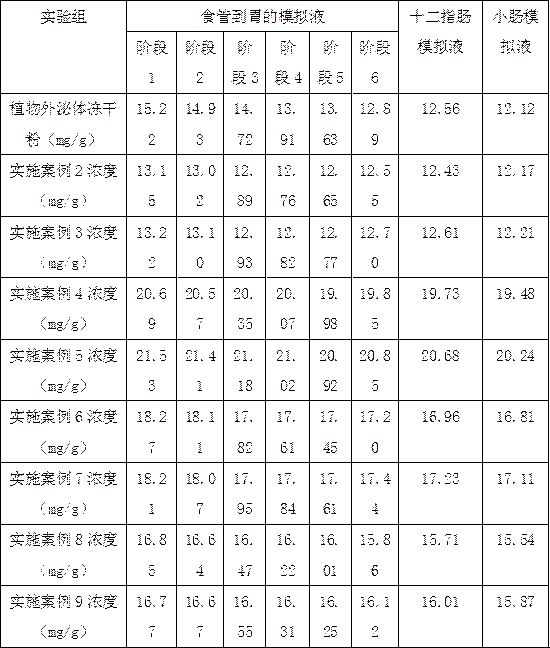

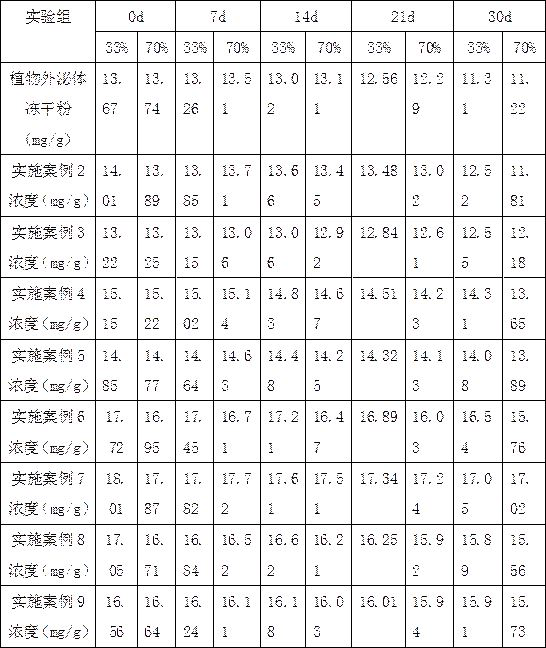

[0042] This embodiment provides a preparation method of ginger exosome microcapsule-embedded freeze-dried powder, which specifically includes the following steps:

[0043] Weigh 150g of fresh ginger and pour it into a juice extractor, add 150ml of sterilized PBS to it, and centrifuge at 3,000g for 20 minutes at 4°C to remove larger residues; take the yellow transparent solution in the middle layer at 10,000g, Centrifuge at 4°C for 70 min; take the supernatant at 120,000g, ultracentrifuge at 4°C for 60 min, then use 1ml sterile PBS to resuspend the pellet and then ultracentrifuge at 120,000g, 4°C for 60 min; after centrifugation, resuspend the pellet with 1ml sterile PBS At this time, the ginger exosome extract is obtained.

[0044] The above ginger exosome extract, sterile sodium alginate solution with a concentration of 30 mg / mL and sterile soybean oil containing 2 μL / mL Tween 80 were mixed at a volume ratio of 1:1:10, using 180 r / min magnetic stirring for 10 min to obtain ...

Embodiment example 3

[0048] This embodiment provides a preparation method of ginger exosome microcapsule-embedded freeze-dried powder, which specifically includes the following steps:

[0049] Weigh 200g of fresh ginger and pour it into a juice extractor, add 200ml of sterilized PBS to it, and centrifuge at 3500g for 30 minutes at 4°C to remove larger residues; Centrifuge at 150,000g for 70 minutes at 4°C for 80 minutes, then use 2ml of sterile PBS to resuspend the pellet and then ultracentrifuge at 150,000g at 4°C for 80 minutes; after centrifugation, resuspend the pellet with 2ml of sterile PBS, At this time, ginger exosomes are obtained.

[0050] Take 80 ml of sodium alginate solution with a mass fraction of 3% and mix it with 90 ml of Ca-EDTA solution with a concentration of 25 mmoL / L, and mix 25 mL of the prepared solution with 15 mL of ginger exosomes, and add to In 70 mL corn germ oil containing 1.2% span80, mechanically stir at 280 r / min for 20 min;

[0051] According to the molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com