Microcapsule fire extinguishing agent and preparation method thereof

A technology of microcapsule and fire extinguishing agent, which is applied in the field of microcapsule fire extinguishing agent and its preparation, which can solve the problems of not having cooling and flame retardant fire extinguishing, the shell does not have flame retardant function, and the fire extinguishing function has not been greatly improved. , to achieve the effects of excellent external temperature thermal response function, excellent environmental protection performance and flame retardant performance, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

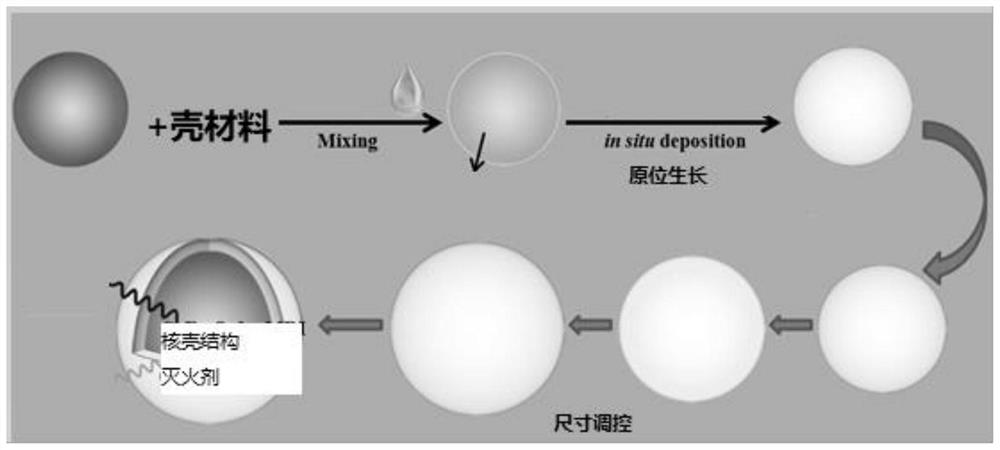

[0039] see figure 1 As shown, the present invention provides a kind of preparation method of microcapsule fire extinguishing agent, specifically adopts in-situ polymerization method, comprises the steps:

[0040] S1. Prepare a predetermined amount of the cooling material solution, add it into a closed reaction vessel, heat it to 60-90°C, and set the reaction pressure to 1.0-1.50Mpa;

[0041] S2. Add a predetermined proportion of the low-melting-point polymer monomer and the flame retardant into the airtight reaction container described in step S1 in sequence, and finally add a predetermined amount of initiator benzoyl peroxide, stir and process, polymerization reaction 2 ~8h, preparing microcapsule particles formed by coating the cooling material with the low melting point copolymer;

[0042] S3. Washing and drying the microcapsule particles prepared in step S2 to obtain the microcapsule fire extinguishing agent.

[0043] Preferably, the mass ratio of the low-melting polymer...

Embodiment 1

[0049] The preparation method of microcapsule fire extinguishing agent:

[0050] S1. Prepare 30g of cooling material fluorinated ketone solution, add it into a closed reaction vessel, heat to 80°C, and set the reaction pressure to 1.0Mpa;

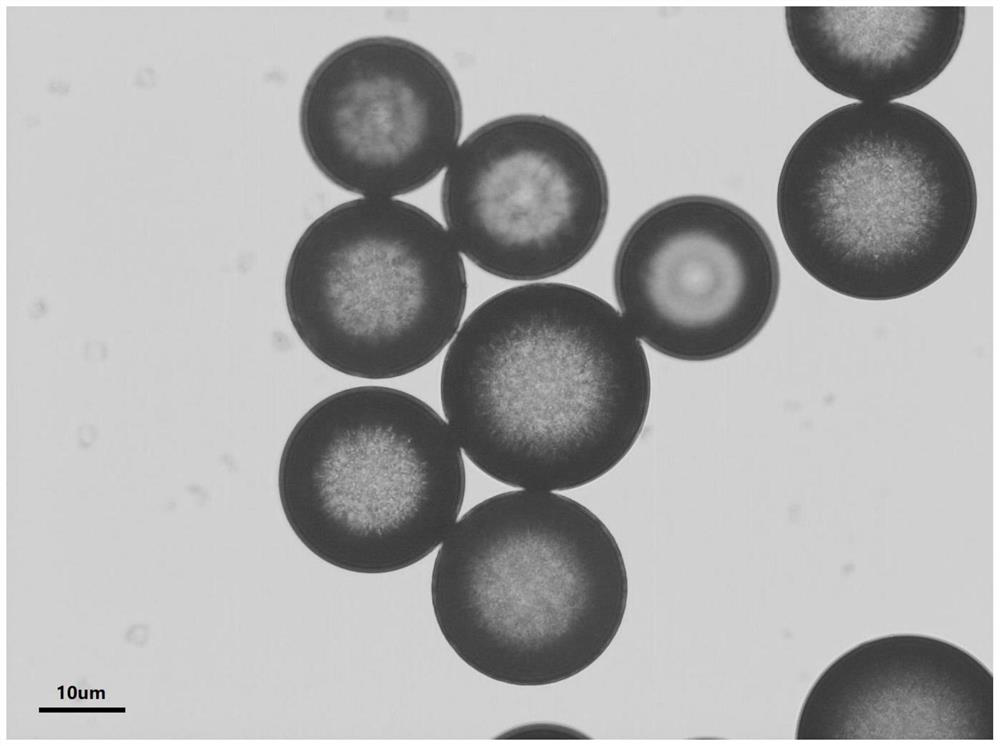

[0051] S2. Add styrene, methyl methacrylate, methacrylic acid and 2-bromo-3,3,3-trifluoropropene with a total mass of 3.3 g to the closed reaction vessel described in step S1 in sequence, and finally add the initiator Benzoyl peroxide, stirred, polymerized for 2 hours, prepared from styrene (St)-methyl methacrylate (MMA)-methacrylic acid (MAA)-2-bromo-3,3,3-trifluoro Microcapsule particles formed by coating fluorinated ketones with propylene (BTP) quaternary copolymerization shell;

[0052] Wherein, in the mass sum of the quaternary comonomers, the mass fractions of the styrene, the methyl methacrylate, the methacrylic acid and the 2-bromo-3,3,3-trifluoropropene are respectively 30%, 20%, 40% and 10%. The addition amount of described ben...

Embodiment 2

[0058] The preparation method of microcapsule fire extinguishing agent:

[0059] S1. Prepare 50g of cooling material fluorinated ketone solution, add it into a closed reaction vessel, heat to 70°C, and set the reaction pressure to 1.5Mpa;

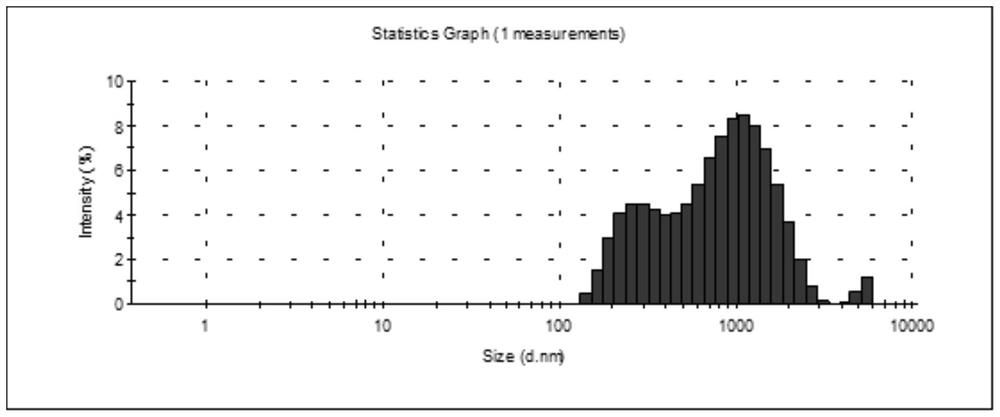

[0060] S2. Add styrene, methyl methacrylate, methacrylic acid and 2-bromo-3,3,3-trifluoropropene with a total mass of 0.5 g to the closed reaction vessel described in step S1 in sequence, and finally add the initiator Benzoyl peroxide, stirred, polymerized for 4h, prepared from styrene (St)-methyl methacrylate (MMA)-methacrylic acid (MAA)-2-bromo-3,3,3-trifluoro Microcapsule particles formed by coating fluorinated ketones with propylene (BTP) quaternary copolymerization shell;

[0061] Wherein, in the mass sum of the quaternary comonomers, the mass fractions of the styrene, the methyl methacrylate, the methacrylic acid and the 2-bromo-3,3,3-trifluoropropene are respectively 30%, 20%, 40% and 10%; the added amount of benzoyl peroxide is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com