Preparation process of tensile solvent-resistant pressure-sensitive adhesive tape

A pressure-sensitive adhesive tape and technology of preparation process, applied in the direction of adhesive types, pressure-sensitive films/sheets, adhesives, etc., can solve the problems of insufficient tensile strength and high temperature solvent resistance, and achieve good and good tearing resistance. High temperature resistance, high flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: The present invention provides a technical solution: a preparation process of tensile and solvent-resistant pressure-sensitive adhesive tape, comprising the following specific steps:

[0029] S1: Prepare the substrate:

[0030] S11: Use PET film as the first film layer, and cut it into the required size for later use;

[0031] S12: Use the textile mechanism to weave the high elastic yarn into a double-layer mesh surface as the second film layer;

[0032] S13: Coating elastic adhesive on the front and back sides of the second film layer, and pasting the first film layer on the front and back sides thereof to form a three-layer structure substrate;

[0033] S2: Preparation of glue:

[0034] S21: Prepare the following raw materials according to weight ratio: 80-120 parts of butyl acrylate, 15-25 parts of 2-ethylhexyl acrylate, 10-18 parts of methyl methacrylate, 2-6 parts of epoxy resin, propylene 0.3-0.8 parts of amide, 0.2-0.7 parts of benzoyl peroxide, ...

Embodiment 2

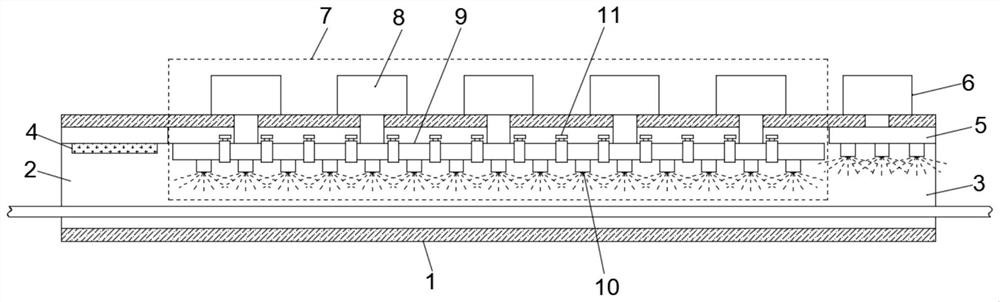

[0041] Example 2: see figure 1, the multi-stage curing drying device includes a drying channel 1 arranged horizontally, and the openings at both ends of the drying channel 1 form a feed port 2 and a discharge port 3 respectively, and a UV curing is installed on the top inner wall near the end of the feed port 2 The lamp tube 4 is equipped with a hollow structure air guide box 5 on the top inner wall near the end of the discharge port 3, and a circulation fan 6 is arranged on the top of the drying channel 1, and the output end of the circulation fan 6 communicates with the air guide box 5.

[0042] In this embodiment, the middle part of the drying channel 1 is set as a multi-stage drying area 7, and the drying channel 1 in the multi-stage drying area 7 is equipped with a plurality of hot air units 8 at equal intervals, and the multi-stage drying area 7 An air supply duct 9 is horizontally arranged inside the drying channel 1 inside, and the output ends of each hot air unit 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com