Masking tape glue and preparation method thereof

A technology of masking paper and tape, applied in the direction of adhesives, sustainable manufacturing/processing, adhesive types, etc., can solve problems such as poor waterproofness, achieve the effects of increased bonding strength, firm connection, and improved mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

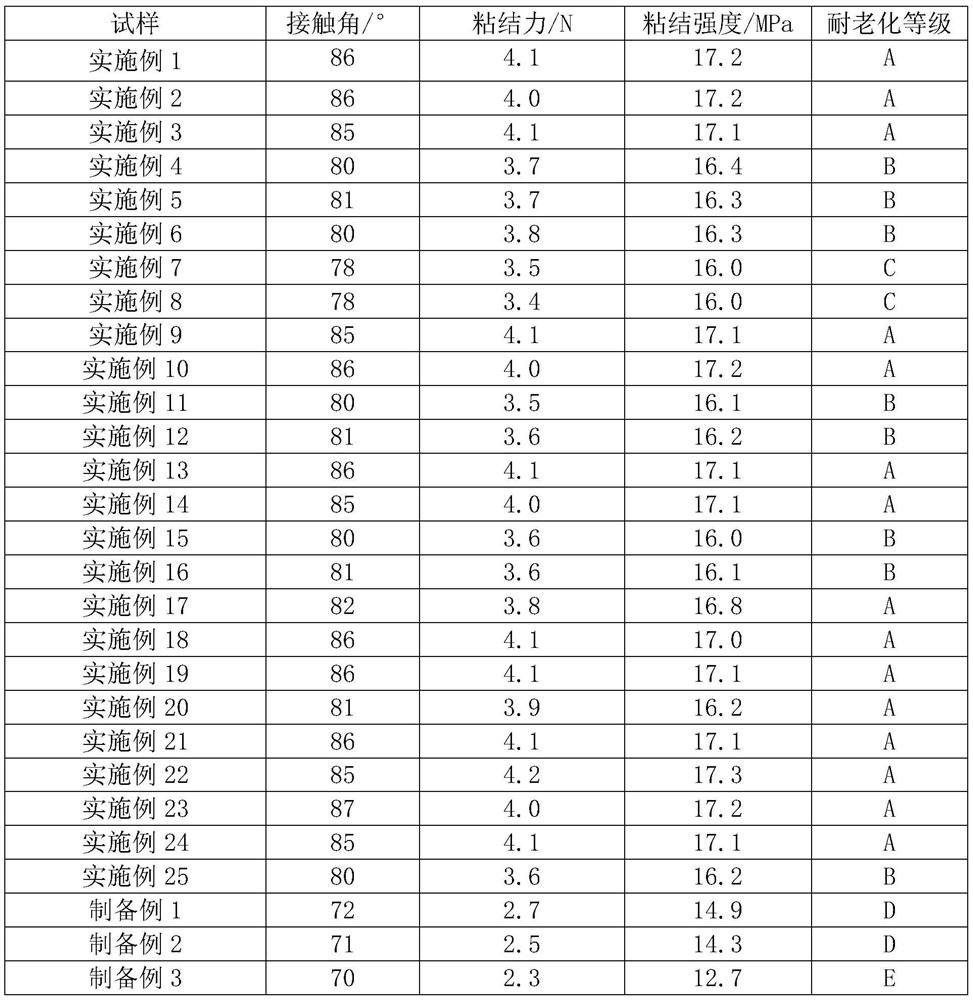

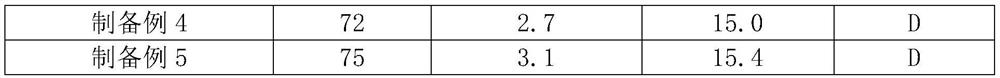

Examples

preparation example 1

[0037] The preparation method of oxidized starch comprises the steps:

[0038] 1), in the water of 37.5 ℃ of 1000ml, add the potato starch that accounts for 50% by weight of water, then stir 40min, then add the ferrous sulfate that accounts for 0.125% by weight of water, continue to stir for 15min, make starch milk:

[0039] 2), continuously dropwise add a sodium hydroxide solution with a mass fraction of 10% into the starch milk, and keep stirring until the pH value of the starch milk is 7.5;

[0040]3), add 500ml of mass fraction 25% hydrogen peroxide solution to the starch milk in step 2), stir for 35min, then continue to add mass fraction of 10% sodium hydroxide solution, and keep stirring until the starch The pH of the milk is 9.5.

preparation example 2

[0042] The preparation method of oxidized starch comprises the steps:

[0043] 1), in 1000ml of water at 30°C, add potato starch that accounts for 40% by weight of water, then stir for 30 minutes, then add ferrous sulfate that accounts for 0.1% by weight of water, and continue stirring for 10 minutes to obtain starch milk:

[0044] 2), continuously dropwise add a sodium hydroxide solution with a mass fraction of 8% into the starch milk, and keep stirring until the pH value of the starch milk is 7;

[0045] 3), add 500ml of mass fraction 20% hydrogen peroxide solution to the starch milk in step 2), stir for 30min, then continue to add mass fraction of 8% sodium hydroxide solution, and keep stirring until the starch Milk has a pH of 9.

preparation example 3

[0047] The preparation method of oxidized starch comprises the steps:

[0048] 1), in 1000ml of water at 45°C, add potato starch that accounts for 60% by weight of water, then stir for 50 minutes, then add ferrous sulfate that accounts for 0.15% by weight of water, and continue stirring for 20 minutes to obtain starch milk:

[0049] 2), continuously dropwise add a sodium hydroxide solution with a mass fraction of 12% into the starch milk, and keep stirring until the pH value of the starch milk is 8;

[0050] 3), add 500ml of mass fraction 30% hydrogen peroxide solution to the starch milk in step 2), stir for 40min, then continue to add mass fraction of 12% sodium hydroxide solution, and keep stirring until the starch The pH of the milk is 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com