Method for laying trenchless new pipeline

A laying method and non-excavation technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as inability to achieve non-excavation or micro-excavation, impact on construction efficiency, and large excavation length, etc., to achieve the laying length Unrestricted, improve construction efficiency and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

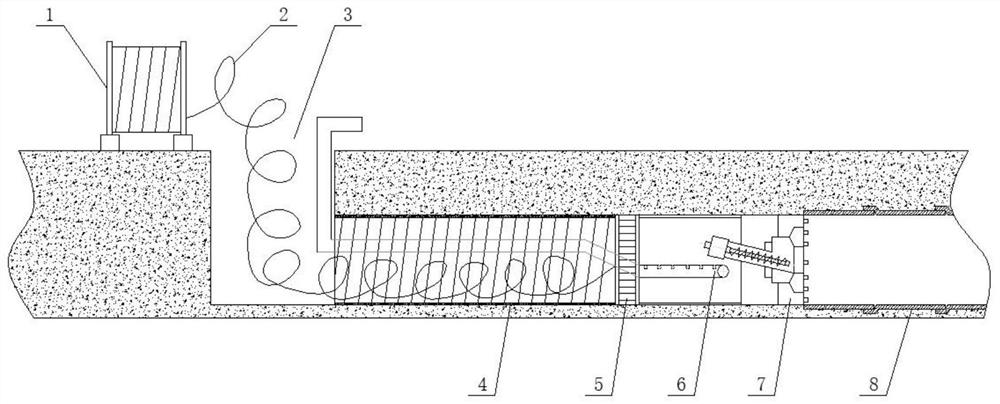

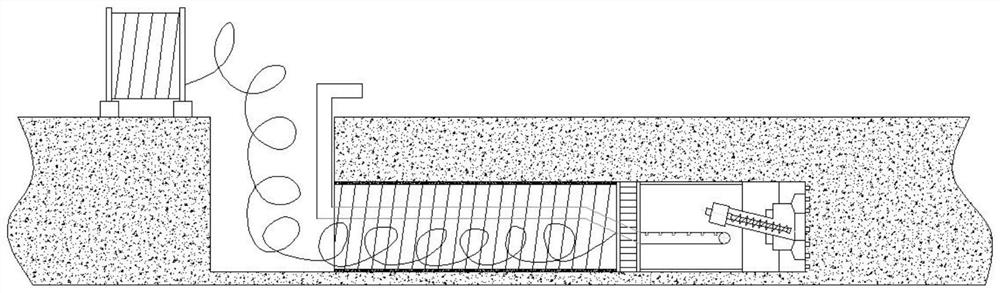

[0023] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0024] A method for laying a new pipeline without excavation, the innovation is that it includes the following steps:

[0025] The first step is to excavate a starting pit 3 and a receiving pit at the starting point and the receiving point according to the size of the new pipeline to be laid, or use the inspection shaft of the original pipeline as the starting pit and the receiving pit respectively, and place the shield The machine and the head walking type spiral winding machine 5 are hoisted into the starting pit respectively, and the bracket 1 for winding the profile 2 is set on one side of the starting pit on the ground;

[0026] In the second step, use the cutting head 7 of the shield machine to break and cut the soil or the old pipeline 8, and then use the soil conveying device 6 of the shield machine to transport the broken soil or the old p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com