Automatic material sliding device and smelting furnace

A smelting furnace and material slipping technology, which is applied in the field of metallurgical equipment, can solve the problems of increasing the workload of dust removal equipment, deteriorating the working environment, air pollution in the workshop, etc., and achieves the effects of novel and compact structure, good high-temperature working environment, and stable and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

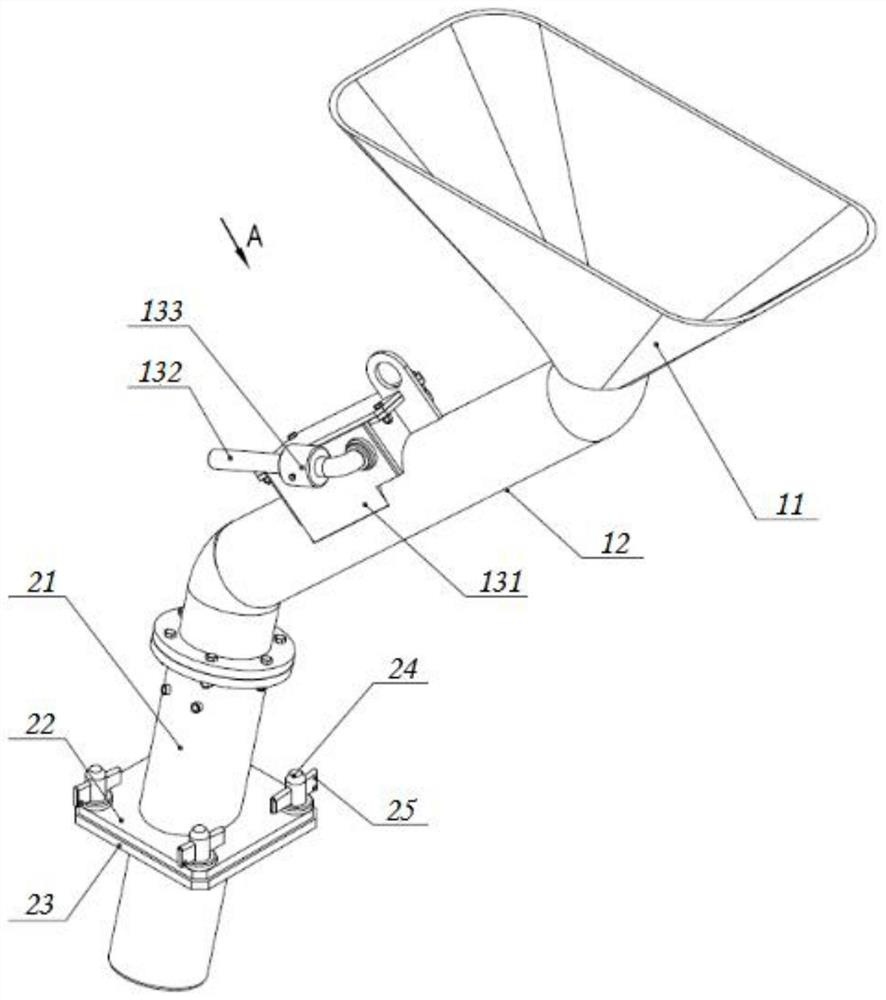

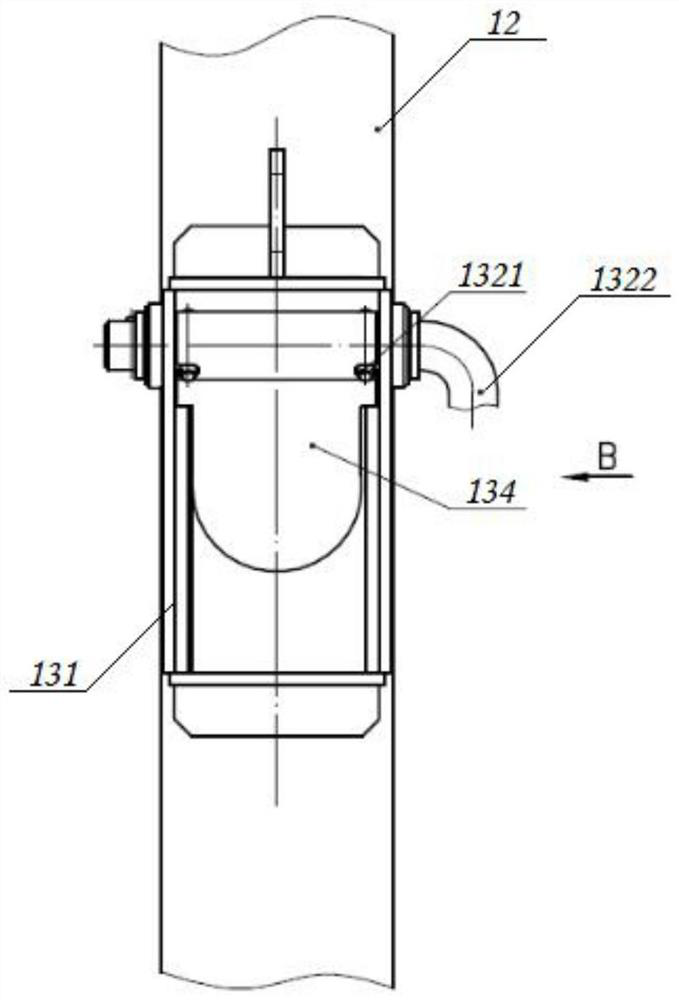

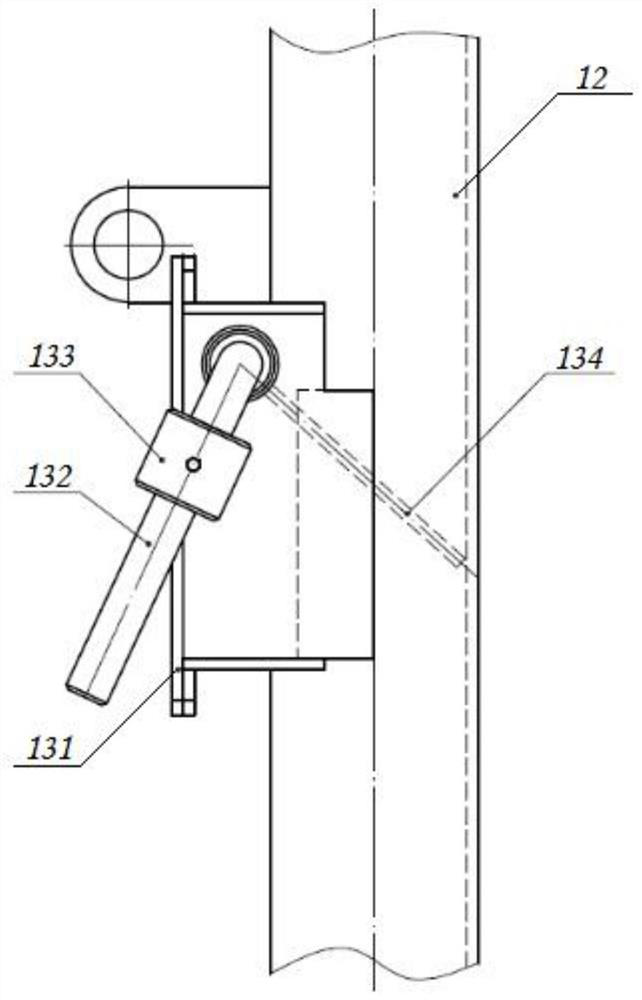

[0025] Such as Figure 1-Figure 3 , the embodiment of the present invention provides an automatic material chute device, comprising a material receiving chute 11 and a material chute 12 connected to the bottom of the material receiving chute 11, the material chute 12 is provided with a material chute control mechanism, the The material slide control mechanism includes a flashboard 134, a moment arm lever 132 and a reset unit; The inner rod section 1321 and the outer rod section 1322 located outside the discharge chute 12; the flashboard 134 is installed on the inner rod section 1321, the reset unit is connected with the outer rod section 1322 and There is a first state where the shutter 134 closes the flow channel of the discharge chute 12 and a second state that follows when the shutter 134 is impacted by materials and drives the lever 132 to rotate.

[0026] Above-mentioned material receiving chute 11 is used for receiving material, and in one of them embodiment, as figure...

Embodiment 2

[0038] An embodiment of the present invention provides a smelting furnace, which includes a furnace body and a furnace cover. The furnace cover is provided with a feeding port, and also includes the automatic material sliding device provided in the first embodiment above. The above feed port connection.

[0039] Since the above-mentioned automatic material slide device adopts a purely mechanical structure, it works stably and reliably, and can better adapt to the high-temperature working environment of the smelting furnace, and can avoid the problems of short service life, many failures and low reliability when using electrical components.

[0040] Among them, preferably, such as figure 1 , a water-cooled slide pipe 21 is installed at the feeding port, and the water-cooled slide pipe 21 is connected to the feeding slide pipe 12; On the furnace cover, the specific position can be adjusted on site, and the mounting plate 22 can be detachably connected with the fixed plate 23 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com