Telegraph pole production line

A production line and utility pole technology, which is applied in the field of utility pole production equipment, can solve problems such as unreasonable layout of utility pole production lines, large manpower and material resources for pouring molds, and low production efficiency, so as to save labor costs, time costs, and land occupation space and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

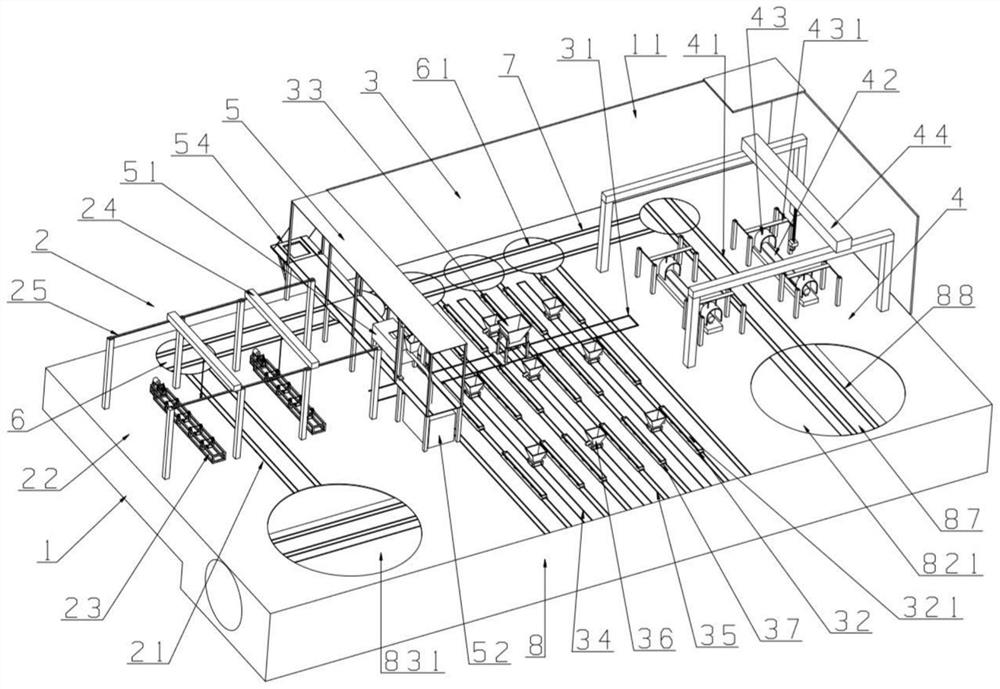

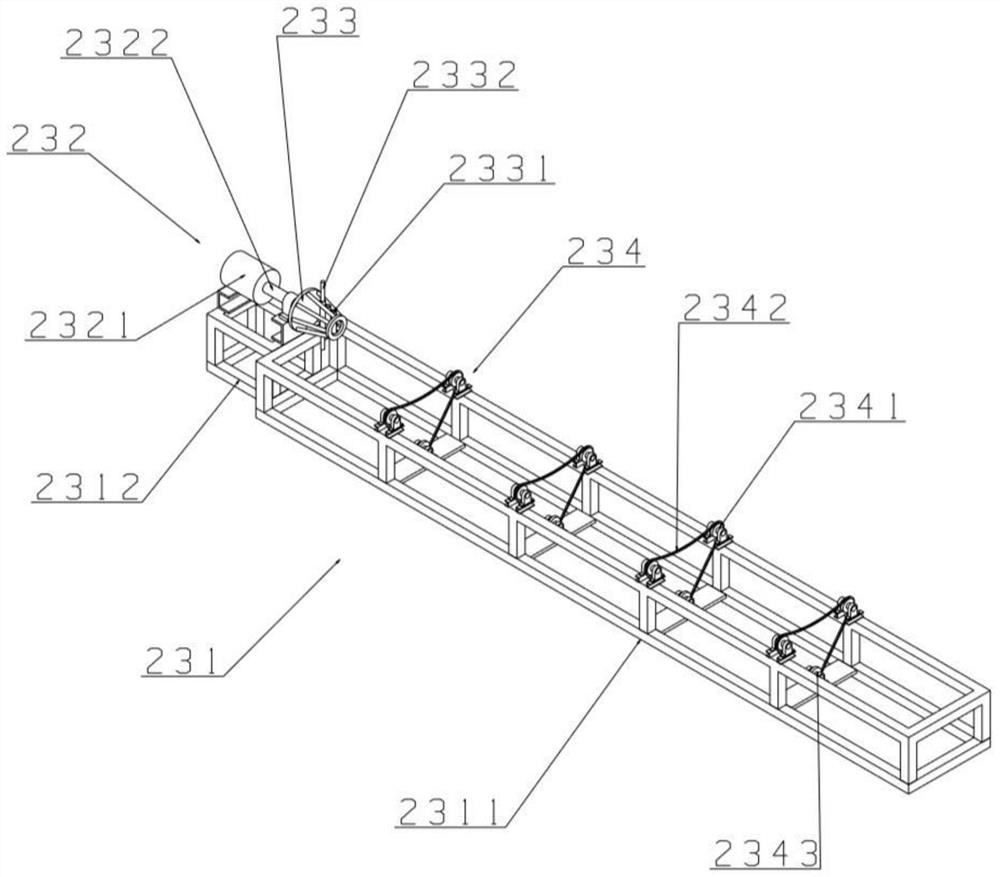

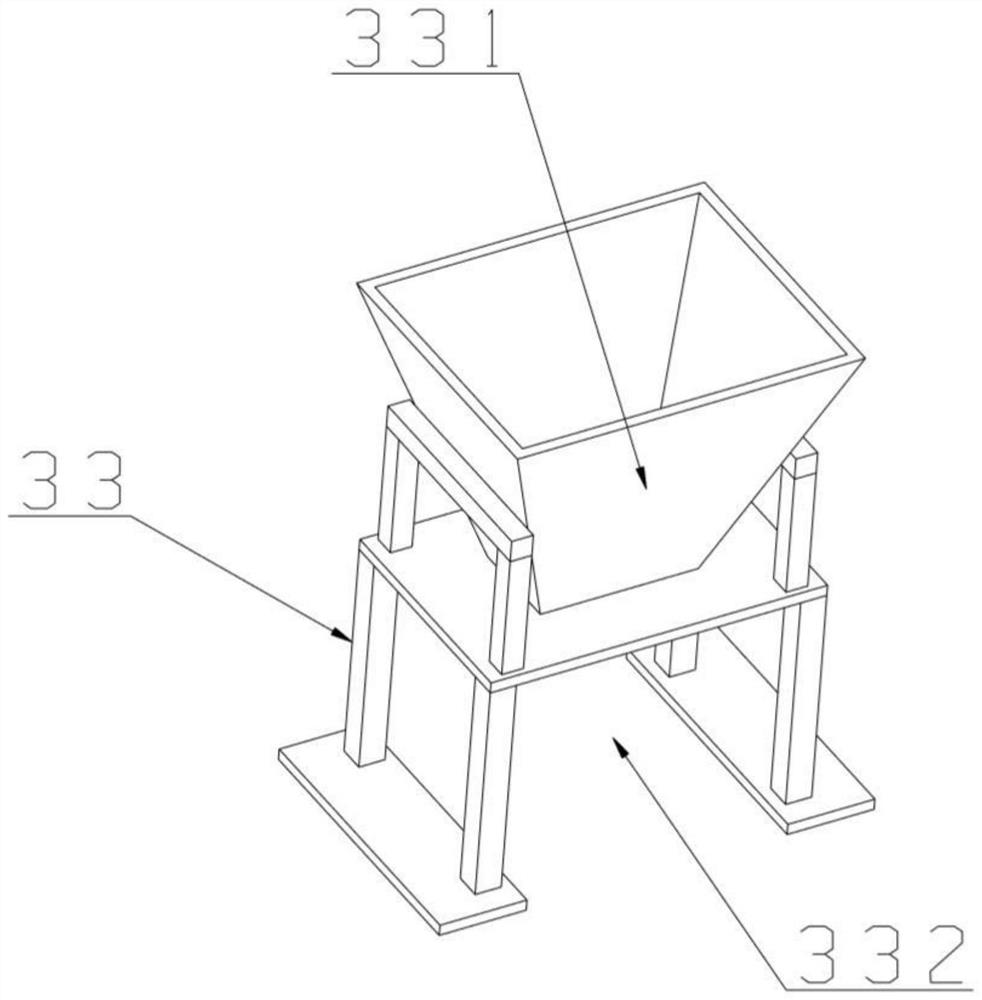

[0041] Such as Figure 1 to Figure 6 As shown, the pole production line in this embodiment includes: foundation 1, workshop 11, cage wire 2, first track 21, welding winding area 22, cage winding machine 23, frame 231, parts support 2311, Motor bracket 2312, rotating assembly 232, rotating motor 2321, rotating shaft 2322, positioner 233, positioning pin sleeve 2331, pin rod 2332, supporting assembly 234, supporting sprocket 2341, supporting chain 2342, tensioning sprocket 2343, the first Crane 24, first hanging rail 25, pouring line 3, second rail 31, mold 32, pouring port 321, transfer car 33, transfer bucket 331, transfer channel 332, third rail 34, fourth rail 35, distribution car 36, distribution hopper 361, mold c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com