Heat treatment process for high-nitrogen stainless bearing steel

A bearing steel, high nitrogen technology, applied in the field of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

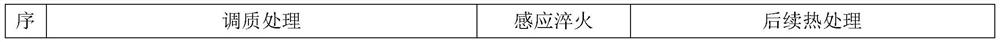

[0015] Step (1) quenching and tempering treatment: quenching, cold treatment and high temperature tempering quenching and tempering treatment of high nitrogen stainless bearing steel, quenching temperature 1000 ℃, holding time 60 minutes, cold treatment temperature -73 ℃, holding time 120 minutes, return to The fire temperature is 580~630℃, and the holding time is 240 minutes;

[0016] Step (2) induction hardening: surface induction hardening is carried out on the material processed in step (1) on a high-frequency induction numerical control hardening machine tool, the power frequency is 25KHz, the heating power is 55KW, the moving speed of the device is 600mm / min, preheating 1.5s, induction hardening The water pressure is 0.3MPa, the quenching time is 8s, the water temperature is 26°C, and the cooling medium is 8-9% water-based quenching liquid.

[0017] Step (3) Subsequent heat treatment: The material treated in step (2) is treated at -73°C or -196°C for 2 hours at a low tem...

Embodiment 2

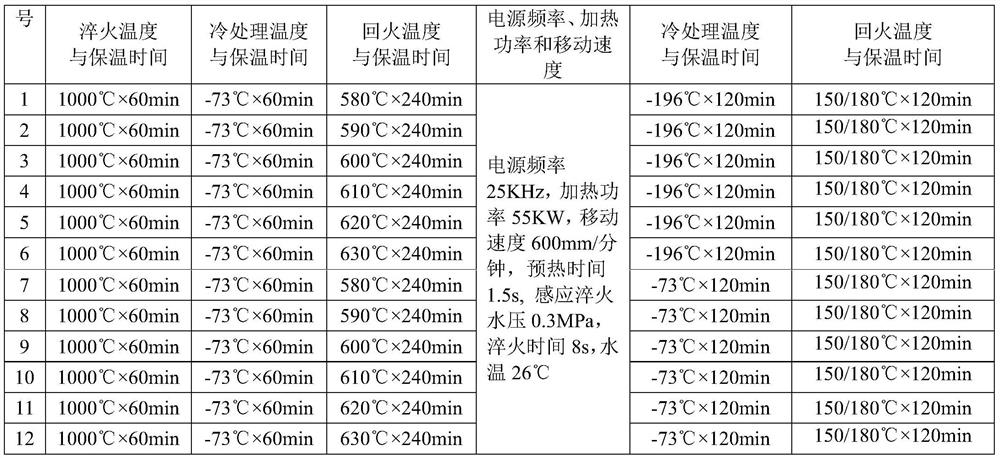

[0021] Step (1) quenching and tempering treatment: quenching, cold treatment and high temperature tempering quenching and tempering treatment of high nitrogen stainless bearing steel, quenching temperature 1000 ℃, holding time 60 minutes, cold treatment temperature -73 ℃, holding time 120 minutes, return to The fire temperature is 580~630℃, and the holding time is 240 minutes;

[0022] Step (2) induction hardening: surface induction hardening is performed on the material processed in step (1) on a high-frequency induction numerical control hardening machine tool, the power frequency is 25KHz, the heating power is 55KW, the device rotation speed is 280mm / min, the heating time is 4.0s, and induction hardening The water pressure is 0.3MPa, the quenching time is 8s, the water temperature is 26°C, and the cooling medium is 8-9% water-based quenching liquid.

[0023] Step (3) Subsequent heat treatment: The material treated in step (2) is treated at -73°C or -196°C for 2 hours at a l...

Embodiment 3

[0027] Step (1) quenching and tempering treatment: quenching, cold treatment and high temperature tempering quenching and tempering treatment of high nitrogen stainless bearing steel, quenching temperature 1000 ℃, holding time 60 minutes, cold treatment temperature -73 ℃, holding time 120 minutes, return to The fire temperature is 580~630℃, and the holding time is 240 minutes;

[0028] Step (2) induction hardening: surface induction hardening is carried out on the material processed in step (1) on a high-frequency induction numerical control hardening machine tool, the power supply frequency is 25KHz, the heating power is 55KW, the device rotation speed is 280mm / min, the heating time is 4.3s, induction hardening The water pressure is 0.3MPa, the quenching time is 8s, the water temperature is 26°C, and the cooling medium is 8-9% water-based quenching liquid.

[0029] Step (3) Subsequent heat treatment: The material treated in step (2) is treated at -73°C or -196°C for 2 hours a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com