Internal fault triggering device for simulating internal fault of lithium battery, test method and application

A technology of internal faults and triggering devices, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems that the actual situation of the internal faults of the battery cannot be accurately simulated, the mechanical strength of the battery shell is damaged, and it is difficult to repeat. Remove the heat transfer process, trigger quickly, and have good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

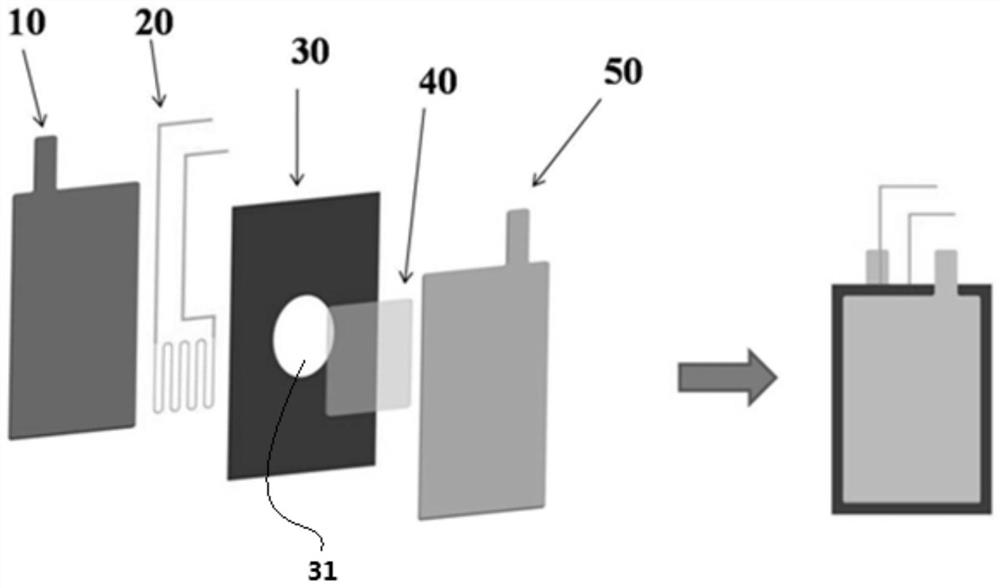

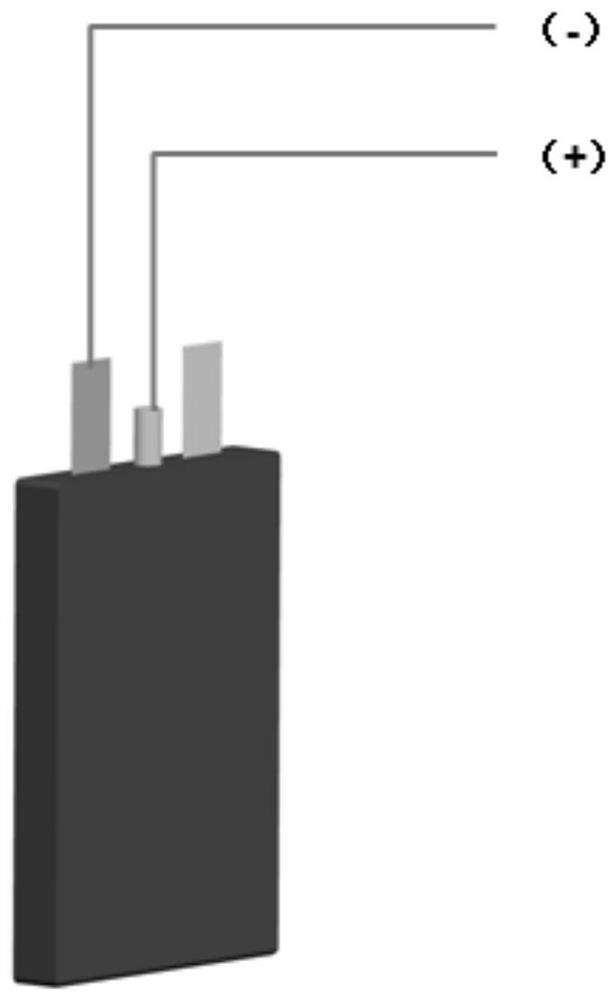

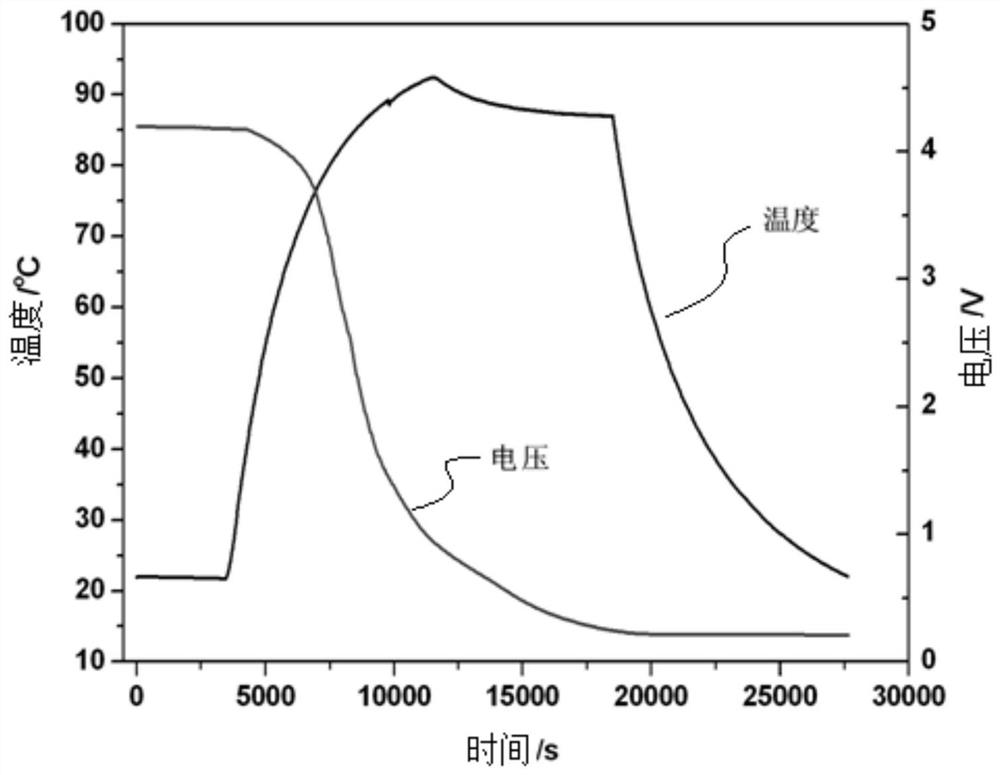

Embodiment 1

[0044] In the aluminum shell lithium-ion battery cell, the diaphragm in the middle of a pair of positive and negative electrodes has a hole, the hole diameter is about 10mm, and a layer of 15mm×15mm low shrinkage temperature diaphragm is covered on it, and a heating wire is placed on the diaphragm, and Lead the heating wire through the negative pole and the special port (the rest of the pole pieces are made normally). The cathode material used is LiCoO 2 , the negative electrode is graphite, the grade of the diaphragm is Celgard 2325, and the test device is shown in figure 1 and figure 2 . figure 2 The middle (+) represents the positive power supply of the heating wire, and the (-) represents the negative power supply of the heating wire. The internal temperature control is controlled by the power supply of the heating wire. Fully charge the battery cell, and when it is necessary to trigger an internal fault, heat the heating wire to a temperature of 55°C to shrink the low-...

Embodiment 2

[0046] The diaphragm in the above test device was changed to a ceramic diaphragm produced by Celgard Company, and other test methods were the same as in Example 1. During the test, the cell did not explode, the battery surface temperature reached a maximum of about 66°C, and the battery voltage gradually decreased to 1.5V within 60 hours. It shows that the separator has higher safety.

Embodiment 3

[0048] Change the cathode material in the above test device to LiFePO 4 , other test methods are the same as in Example 1. During the test, the cell did not explode, the surface temperature of the battery reached a maximum of about 59°C, and the battery voltage gradually decreased to 1.3V within 60 hours. It shows that the positive electrode material compared with LiCoO 2 With higher security.

[0049] The internal fault triggering device for simulating internal faults of lithium batteries of the present invention can not only evaluate the safety of batteries of different systems, but also improve and evaluate batteries with poor safety in a targeted manner, such as improving diaphragms or positive electrode materials, Negative electrode materials are improved.

[0050] In summary, the present invention introduces the low-temperature heat-shrinkable film and the electric heating wire into the battery system, and the low-temperature heat-shrinkable film is shrunk by means of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com