Preparation method of foamed aluminum structural part and foamed aluminum structural part

A technology for foamed aluminum and structural parts, which is applied in the field of preparation of foamed aluminum structural parts and foamed aluminum structural parts. It can solve the problems of structural strength influence, increased plate weight, complex production process, etc., so as to improve the impact resistance and increase the scope of application. , Improve the effect of man-machine environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

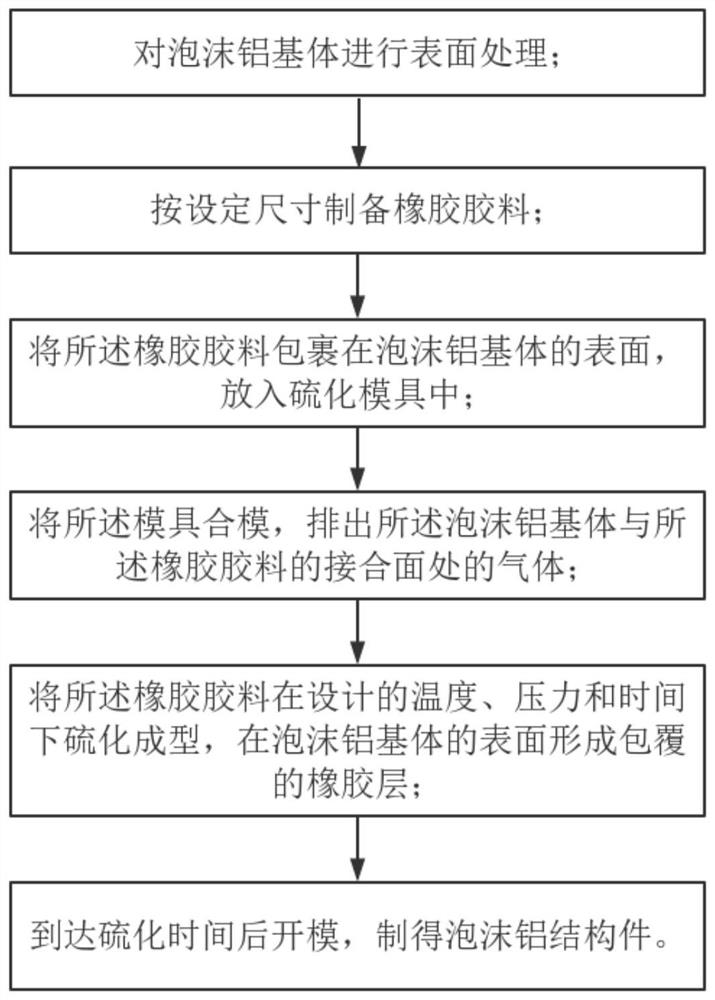

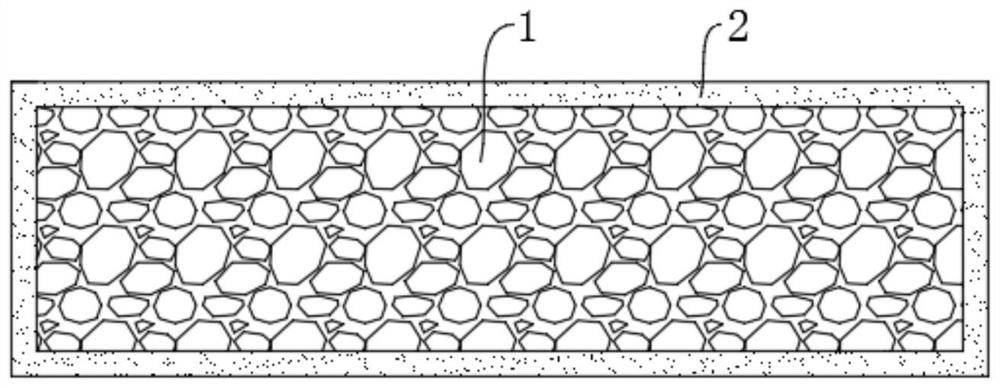

[0038] A method for preparing a foamed aluminum structure, combining figure 1 , including the following steps:

[0039] Step 1, prepare the aluminum foam matrix 1, the aluminum foam matrix 1 is a cuboid with a porosity of 60%, wash the surface of the aluminum foam matrix 1 with acetone, dry it in an oven at 60°C, and then place it on the aluminum foam matrix 1 The surface of the surface is sprayed with Kemlok adhesive, the coating thickness of the Kemlok adhesive is 0.6mm, and it is dried in an oven at 60°C.

[0040] Step 2, prepare a rubber compound according to the surface shape of the aluminum foam substrate 1, the thickness of the rubber compound is 5 mm.

[0041] Step 3: Wrap the rubber compound on the surface of the aluminum foam matrix 1, prepare a vulcanization mold, preheat the mold at a temperature of 150°C, and put the aluminum foam matrix 1 wrapped with the rubber compound into the mold.

[0042] Step 4, the mold is closed, and the gas at the joint surface of the...

Embodiment 2

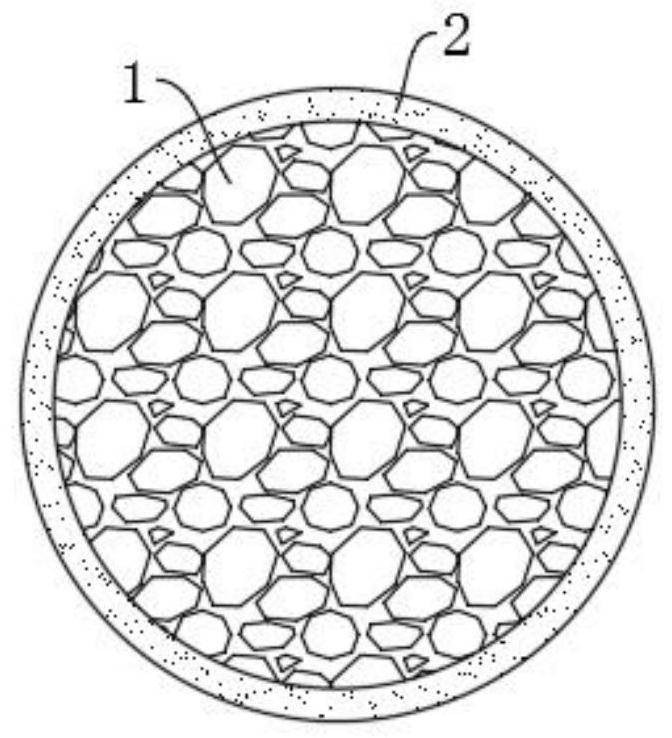

[0046] A method for preparing a foamed aluminum structure, comprising the following steps:

[0047] Step 1, prepare the aluminum foam matrix 1, the aluminum foam matrix 1 is cylindrical, and the porosity is 50%, the surface of the aluminum foam matrix 1 is washed with acetone, placed in an oven at 45°C for drying, and then placed on the aluminum foam matrix The surface of 1 is sprayed with Kemlok adhesive, the coating thickness of the Chemlok adhesive is 0.45mm, and it is dried in an oven at 60°C.

[0048] Step 2, prepare a rubber compound according to the surface shape of the aluminum foam substrate 1, the thickness of the rubber compound is 3 mm.

[0049] Step 3: Wrap the rubber compound on the surface of the aluminum foam matrix 1, prepare a vulcanization mold, preheat the mold at a temperature of 70°C, and put the aluminum foam matrix 1 wrapped with the rubber compound into the mold.

[0050] Step 4, the mold is closed, and the gas at the joint surface of the aluminum foa...

Embodiment 3

[0054] A method for preparing a foamed aluminum structure, comprising the following steps:

[0055] Step 1, prepare the foamed aluminum substrate 1, the foamed aluminum substrate 1 is trapezoidal, the porosity is 65%, the surface of the foamed aluminum substrate 1 is cleaned with alcohol, air-dried at normal temperature, and then sprayed on the surface of the foamed aluminum substrate 1 The coating thickness of Chemlok adhesive is 1.95mm, and it is air-dried at room temperature.

[0056] Step 2, preparing a rubber compound according to the surface shape of the foamed aluminum substrate 1, and the thickness of the rubber compound is 10mm.

[0057] Step 3: Wrap the rubber compound on the surface of the aluminum foam matrix 1, prepare a vulcanization mold, preheat the mold at a temperature of 145°C, and put the aluminum foam matrix 1 wrapped with the rubber compound into the mold.

[0058] Step 4, open and close the mold to discharge the gas at the joint surface between the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com