MoO3-coated high-nickel ternary positive electrode material and preparation method thereof

A positive electrode material and high-nickel technology, which is applied in the field of MoO3-coated high-nickel ternary positive electrode materials and its preparation, can solve the problems of high particle size requirements, unsatisfactory coating effect, solid phase particle agglomeration, etc., and achieve the purpose of suppressing particle size. The effect of agglomeration, uniform coating, and simple production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

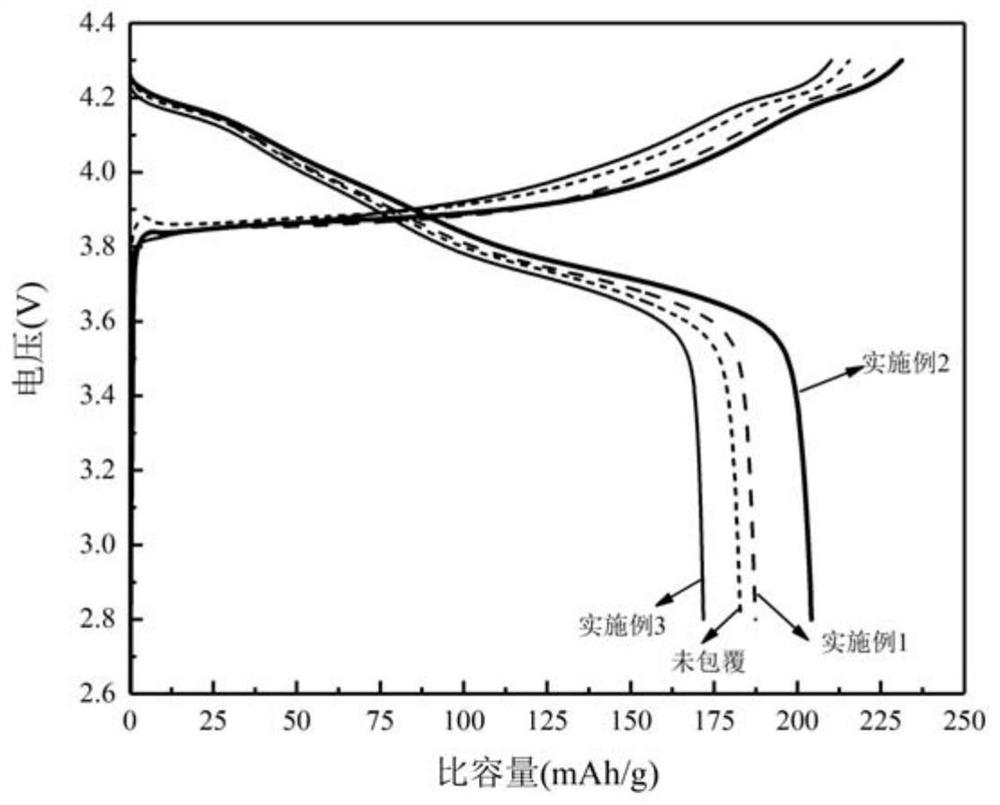

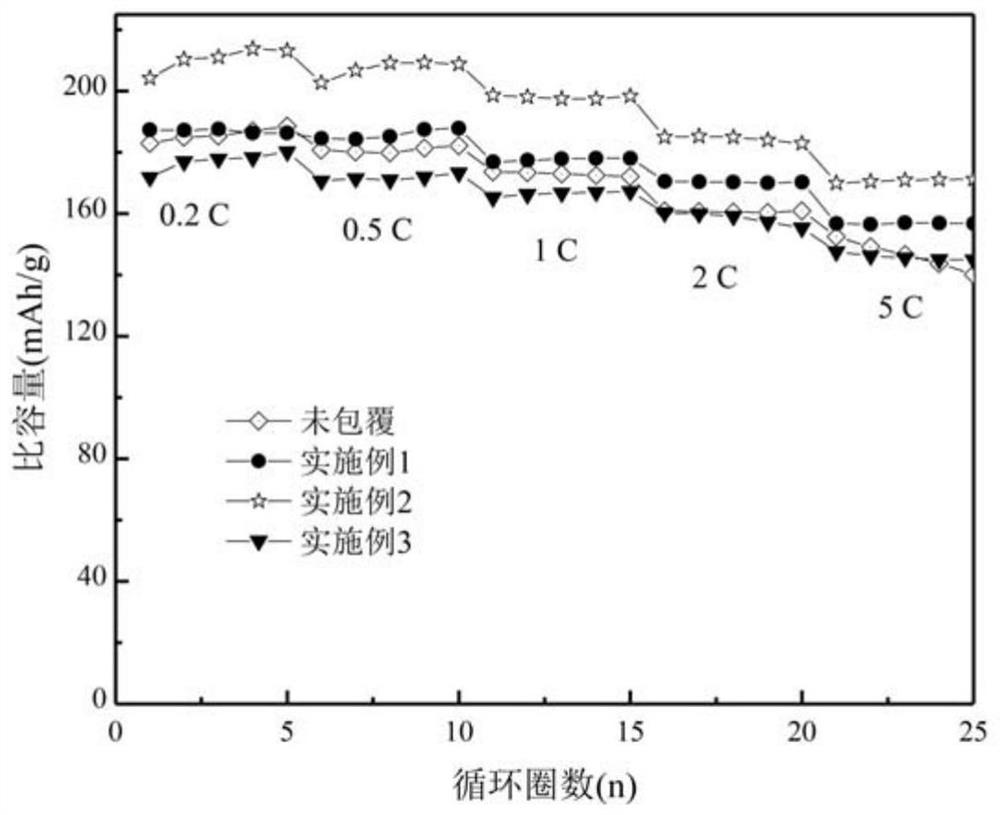

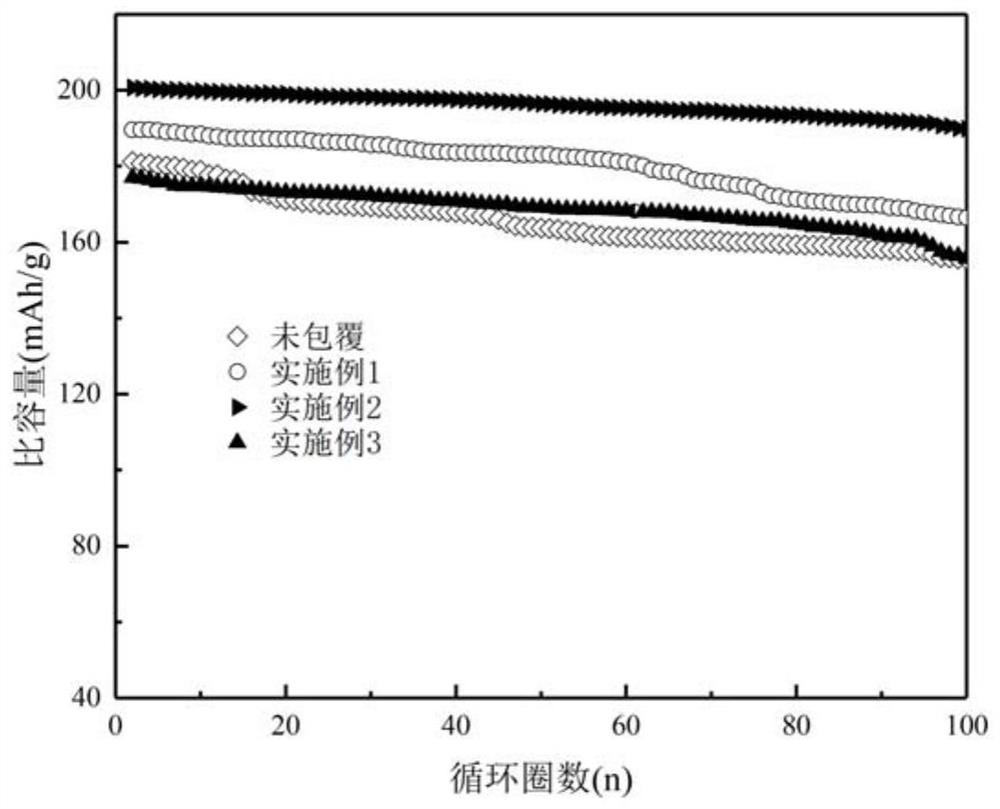

Embodiment 1

[0031] An embodiment of the present application, the MoO described in the embodiment 3 A method for preparing a coated high-nickel ternary positive electrode material, comprising the steps of:

[0032] (1) Ammonium molybdate is dissolved in deionized water to obtain a coating solution;

[0033] (2) Add high-nickel ternary precursor material Ni to the coating solution obtained in step (1). 0.8 co 0.1 mn 0.1 (OH) 2 and LiOH·H 2 O, carry out magnetic stirring, and obtain suspension liquid after stirring evenly; Wherein, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of transition metals in: LiOH·H 2 O: Ni 0.8 co 0.1 mn 0.1 (OH) 2 Transition metal in =1.02:1; Ammonium molybdate in step (1) and Ni in step (2) 0.8 co 0.1 mn 0.1 (OH) 2 The mass ratio is: ammonium molybdate: Ni 0.8 co 0.1 mn 0.1 (OH) 2 =1:100;

[0034] (3) Spray-dry the suspension obtained in step (2) to obtain a precipitate, and carry out high-temperature calcination to the precipit...

Embodiment 2

[0036] An embodiment of the present application, the MoO described in the embodiment 3 A method for preparing a coated high-nickel ternary positive electrode material, comprising the steps of:

[0037] (1) Ammonium molybdate is dissolved in deionized water to obtain a coating solution;

[0038] (2) Add high-nickel ternary precursor material Ni to the coating solution obtained in step (1). 0.8 co 0.1 mn 0.1 (OH) 2 and LiOH·H 2 O, carry out magnetic stirring, and obtain suspension liquid after stirring evenly; Wherein, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of transition metals in: LiOH·H 2 O: Ni 0.8 co 0.1 mn 0.1 (OH) 2 Transition metal in =1.04:1; Ammonium molybdate in step (1) and Ni in step (2) 0.8 co 0.1 mn 0.1 (OH) 2 The mass ratio is: ammonium molybdate: Ni 0.8 co 0.1 mn 0.1(OH) 2 =3:100;

[0039] (3) Spray-dry the suspension obtained in step (2) to obtain a precipitate, and carry out high-temperature calcination to the precipita...

Embodiment 3

[0041] An embodiment of the present application, the MoO described in the embodiment 3 A method for preparing a coated high-nickel ternary positive electrode material, comprising the steps of:

[0042] (1) Ammonium molybdate is dissolved in deionized water to obtain a coating solution;

[0043] (2) Add high-nickel ternary precursor material Ni to the coating solution obtained in step (1). 0.8 co 0.1 mn 0.1 (OH) 2 and LiOH·H 2 O, carry out magnetic stirring, and obtain suspension liquid after stirring evenly; Wherein, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of transition metals in: LiOH·H 2 O: Ni 0.8 co 0.1 mn 0.1 (OH) 2 Transition metal in =1.06:1; Ammonium molybdate in step (1) and Ni in step (2) 0.8 co 0.1 mn 0.1 (OH) 2 The mass ratio is: ammonium molybdate: Ni 0.8 co 0.1 mn 0.1 (OH) 2 =5:100;

[0044] (3) Spray-dry the suspension obtained in step (2) to obtain a precipitate, and carry out high-temperature calcination to the precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com