Fuel cell stack durability acceleration test method and durability acceleration test device

A fuel cell stack and testing method technology, which is applied in the fields of fuel cells, fuel cell additives, fuel cell heat exchange, etc. Avoid insufficient supply of reactive gas, fast and accurate dynamic response, and alleviate the effect of gas response lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

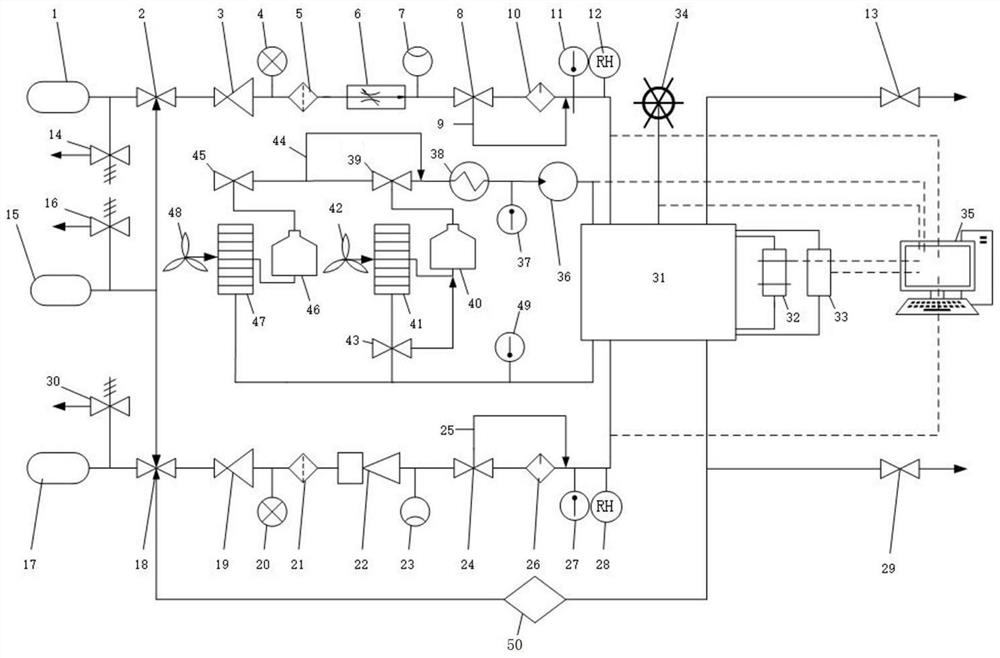

[0091] Such as figure 1 As shown, the fuel cell stack durability accelerated test device provided by the embodiment of the present invention is provided with a high-pressure air source 1, a nitrogen source 15, and a high-pressure hydrogen source 17 communicated with the fuel cell stack 31 through pipelines, and an electronic load 32 and Electrochemical workstation 33;

[0092] The pipeline between the high-pressure air source 1 and the fuel cell stack 31 is sequentially connected with a first three-way valve 2, a first pressure reducing valve 3, a first pressure sensor 4, a first filter 5, an air flow controller 6, The first flow sensor 7, the first bypass valve 8, the first humidifier 10, the first temperature sensor 11 and the first humidity sensor 12;

[0093] The pipeline between the high-pressure hydrogen source 17 and the fuel cell stack 31 is sequentially connected with a second three-way valve 18, a second pressure reducing valve 19, a second pressure sensor 20, a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com