Bendable rigid circuit board and preparation method thereof

A circuit board and rigid technology, applied in the field of bendable rigid circuit board and its preparation, can solve the problems of high production and processing costs, inconvenient use, cumbersome design process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

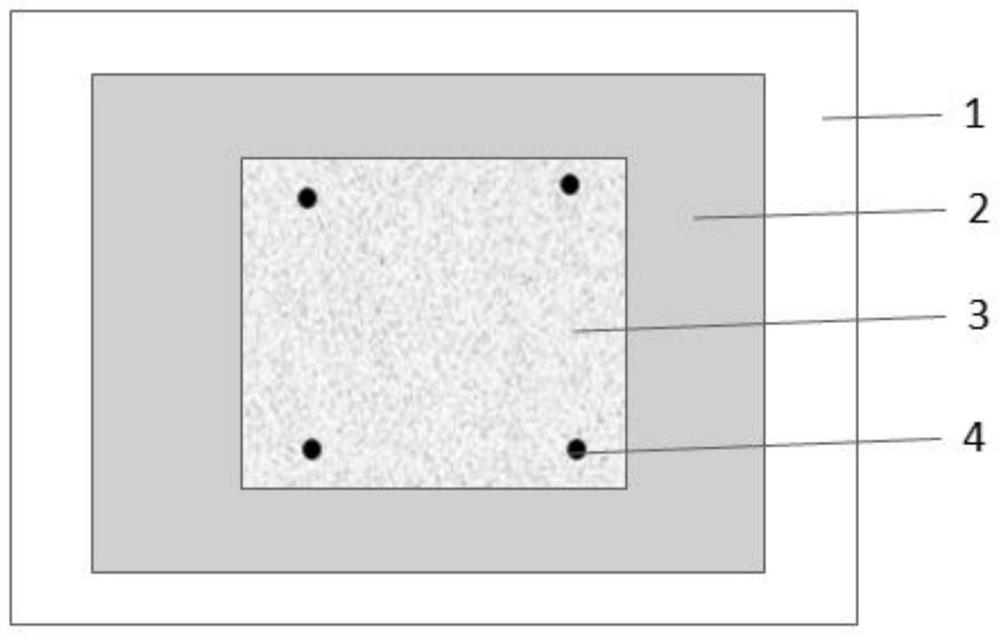

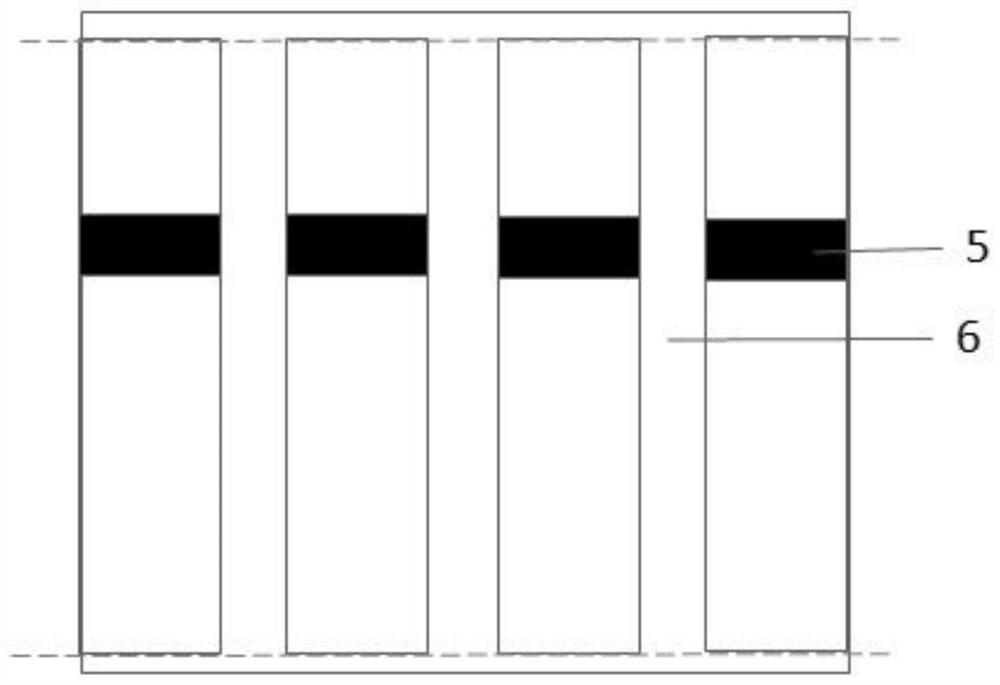

[0034] Such as Figure 1-2 As shown, a bendable rigid circuit board includes an intermediate core board arranged in the middle, copper foil layers arranged on both sides of the intermediate core board, and an environmentally friendly solder resist layer arranged outside the copper foil layer. The rigid circuit board is provided with There is a blind slot 5, and the rigid circuit board is provided with an inner slot 6 in the vertical direction of the blind slot 5.

[0035] Further, the blind groove 5 passes through the middle core board, the copper foil layer on the upper layer of the middle core board and the environmental protection solder resist layer on the upper layer of the copper foil layer, and does not pass through the copper foil layer on the lower layer of the middle core board and the environmental protection solder resist layer on the lower layer of the copper foil layer. solder layer.

[0036] Further, the intermediate core board is composed of resin glue and fib...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is:

[0051] The intermediate core board is composed of resin glue and fibers, the fibers are a mixture of organic fibers and inorganic fibers, and the mixing ratio of organic fibers and inorganic fibers is 1:3.

[0052] The organic fiber is a mixture of high-density polyethylene and cycloolefin copolymer elastomer fiber, graphene-modified nylon fiber, and semi-carbonized cellulose, and the mixing ratio is 3:2:1.

[0053] The inorganic fiber is a mixture of glass fiber, asbestos fiber and ceramic fiber, and the mixing ratio is 3:1:2.

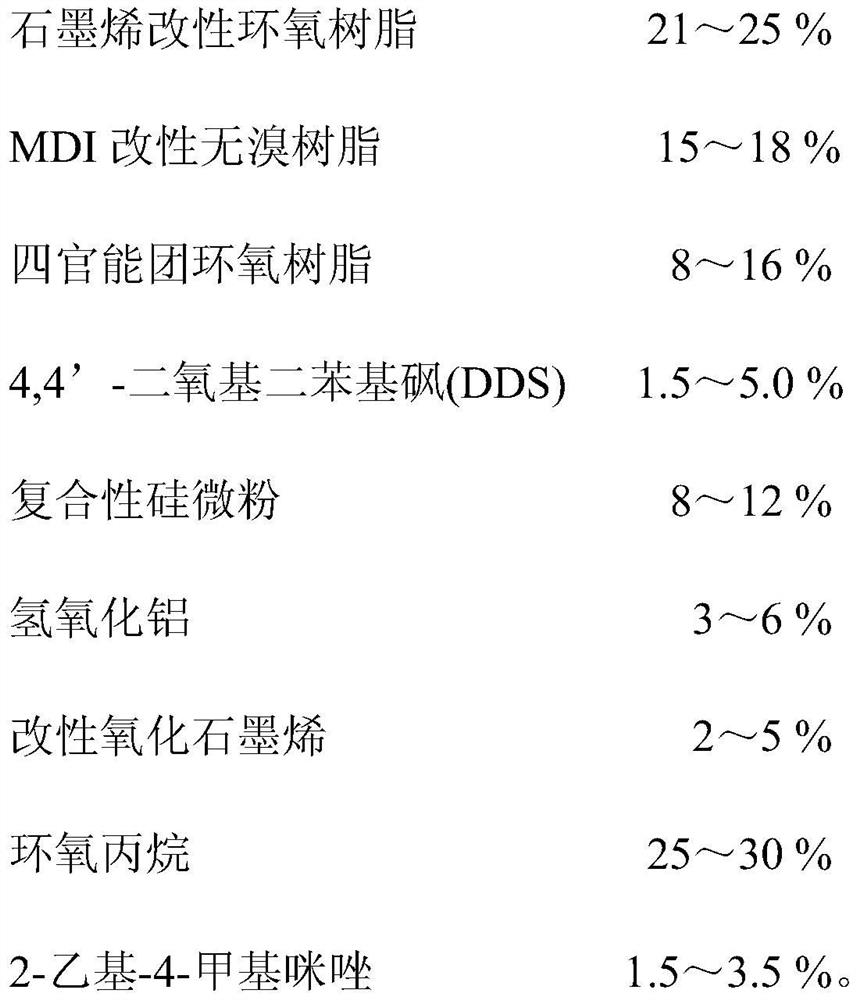

[0054] Further, the resin glue includes the following composition raw materials in weight percentage:

[0055]

[0056]

[0057] A method for preparing a bendable rigid circuit board. The preparation method is based on a preparation system. The preparation system includes a hot press machine, a forming machine and a numerically controlled milling machine. The forming machine inc...

Embodiment 3

[0066] The difference between this embodiment and embodiment 1, 2 is:

[0067] The intermediate core board is composed of resin glue and fibers, the fibers are a mixture of organic fibers and inorganic fibers, and the mixing ratio of organic fibers and inorganic fibers is 1:5.

[0068] The organic fiber is a mixture of high-density polyethylene and cycloolefin copolymer elastomer fiber, graphene-modified nylon fiber, and semi-carbonized cellulose, and the mixing ratio is 4:2:1.

[0069] The inorganic fiber is a mixture of glass fiber, asbestos fiber and ceramic fiber, and the mixing ratio is 4:1:3.

[0070] Further, the resin glue includes the following composition raw materials in weight percentage:

[0071]

[0072]

[0073] A method for preparing a bendable rigid circuit board. The preparation method is based on a preparation system. The preparation system includes a hot press machine, a forming machine and a numerically controlled milling machine. The forming machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com