Flue gas desulfurization process for miniature industrial gas-fired boiler

A technology for industrial gas and desulfurization process, applied in the field of flue gas desulfurization process, can solve the problems of high investment cost, difficult to handle desulfurization by-products, and difficult to handle micro-industrial gas furnace desulfurization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

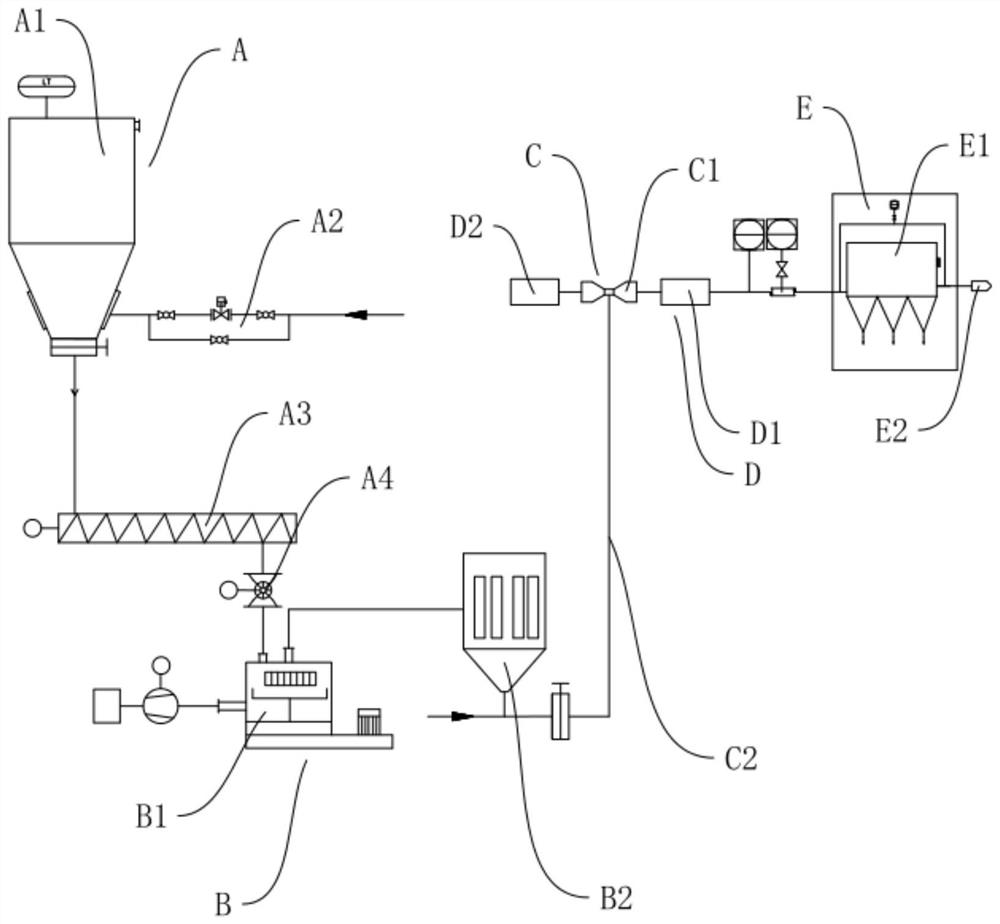

[0045] This implementation discloses a flue gas desulfurization system for micro-industrial gas-fired boilers, please refer to figure 1 As shown, it includes desulfurization agent storage system A, desulfurization agent grinding system B, dry powder injection system C, mixing system D and dust removal system E.

[0046] Desulfurizer storage system A includes desulfurizer storage bin A1, pneumatic conveying device A2, screw feeder A3 and weighing device A4, desulfurizer storage bin A1 is used to store baking soda granule desulfurizer, and pneumatic conveying device A2 passes through the pipeline Unicom desulfurizer storage bin A1 and screw feeder A3 can transport the baking soda particles in the desulfurizer storage bin A1 to the screw feeder A3, the end 24 of the screw feeder A3 is connected with the weighing device A4, through the screw feeder A3 The output baking soda granules are weighed by the weighing device A4 to realize the feeding accuracy of the baking soda granules a...

Embodiment 2

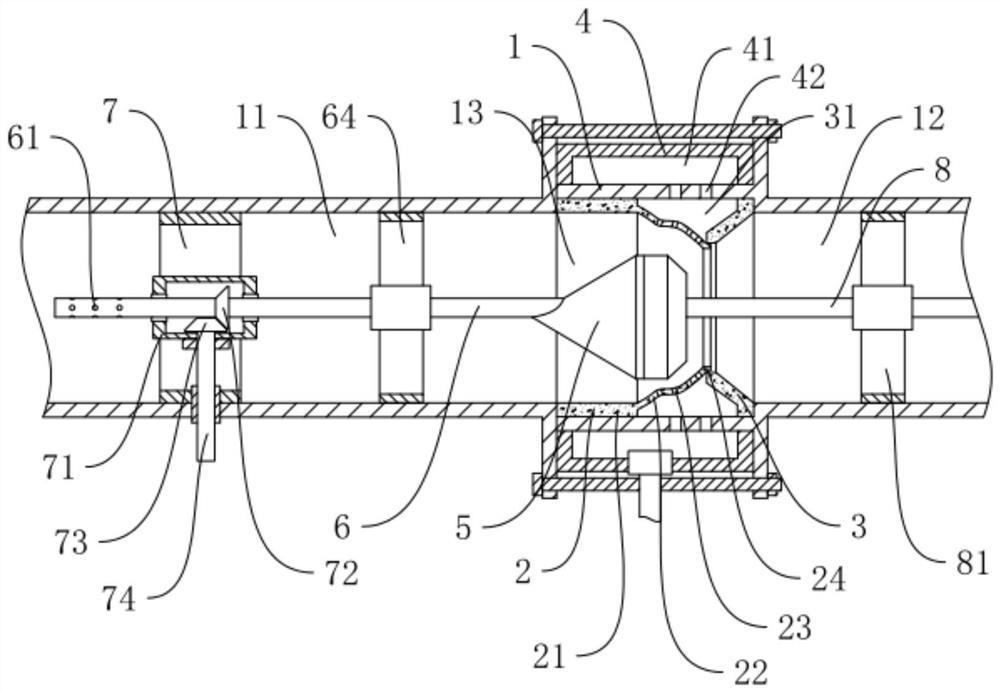

[0057] This implementation discloses another flue gas desulfurization system for micro-industrial gas-fired boilers. On the basis of Embodiment 1, refer to figure 2 As shown, the injection device C1 in the flue gas desulfurization system is further optimized.

[0058] The injection device C1 includes a mixing tube 1, and the two ends of the mixing tube 1 are respectively connected to the flue gas input pipe D2 by connecting the input pipe 11 and the output pipe 12. The mixing pipe 1 is provided with a necking pipe 2, and the necking pipe 2 includes equal-diameter Section 21 and necking section 22, the outer diameter of the equal-diameter end is consistent with the inner diameter of the mixing tube 1, the necking section 22 extends toward the output pipe 12 side, and the diameter gradually decreases;

[0059] The mixing tube 1 is also provided with a trumpet-shaped necking ring 3, the necking ring 3 is located on one side of the output pipe 12, the outer diameter of the large ...

Embodiment 3

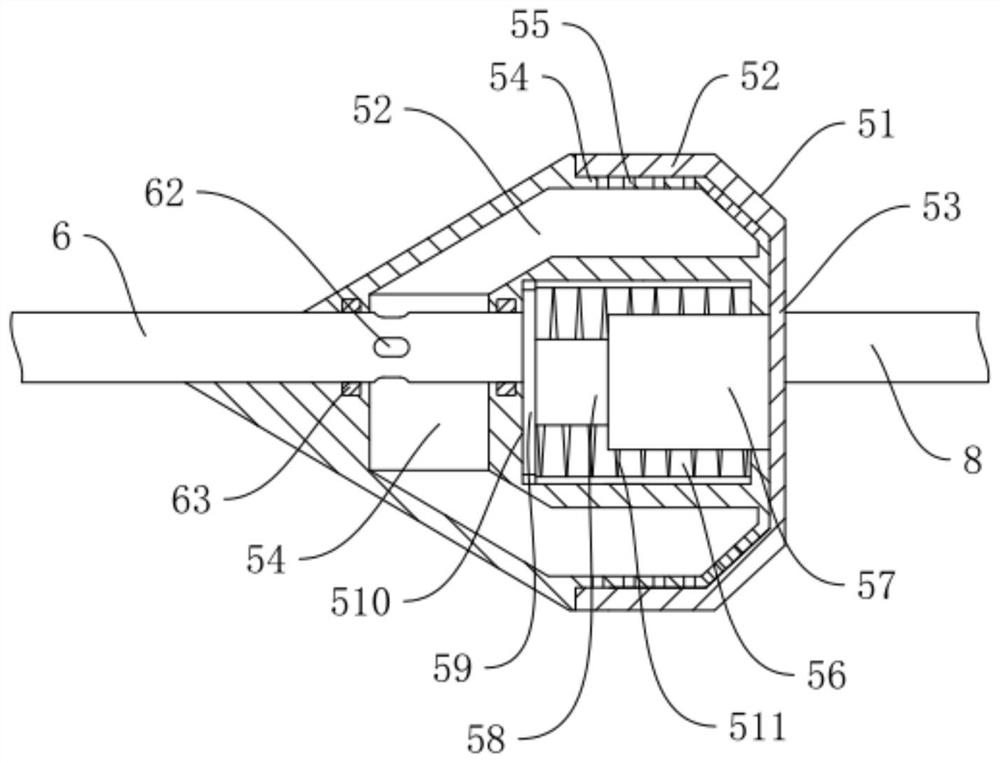

[0071] This implementation discloses another flue gas desulfurization system for micro-industrial gas-fired boilers. On the basis of Embodiment 2, refer to Figure 3-Figure 5 As shown, the injection device C1 in the flue gas desulfurization system is further optimized.

[0072] The flow limiting plug 5 mainly includes two parts, a plug body 51 and a sliding sleeve 52. The inside of the plug body 51 is provided with a pressure stabilizing chamber 54, and the outer periphery of the plug body 51 is provided with a number of stabilizing holes 55, and the stabilizing holes 55 connect the stabilizing chamber 54 communicates with the inner cavity of the mixing tube 1, the middle position of the plug body 51 is the outer cylindrical section 53, and the pressure stabilizing hole 55 is located on the cylindrical section 53; one end of the stabilizing tube 6 extends into the stabilizing chamber 54 and is provided with an air outlet 62. The other end of the voltage regulator tube 6 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com