SCR denitration ammonia spraying control method, device, equipment and medium

A control method and denitration technology, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of poor accuracy and slow adjustment of ammonia injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The present application examples have solved technical problems in the prior art in ammonia in the prior art slow and accuracy difference.

[0051]The technical solution of the present application example is to solve the above technical problems, the overall idea is as follows:

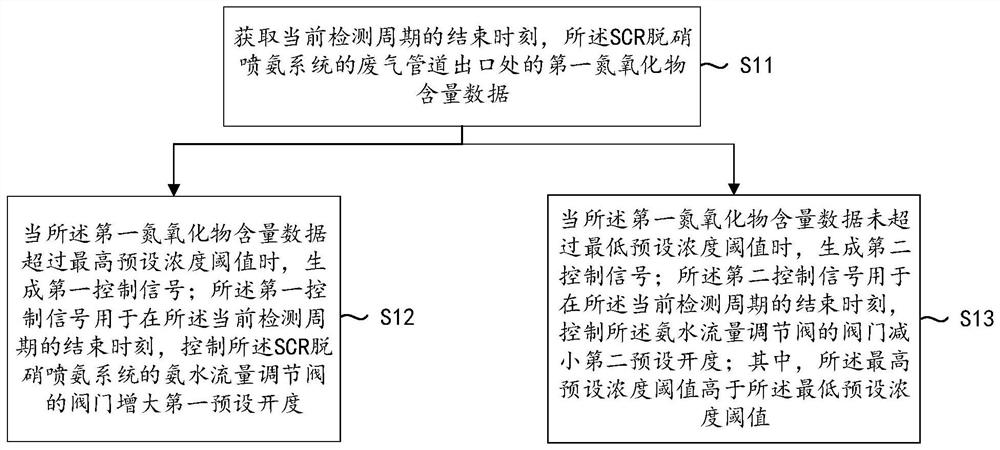

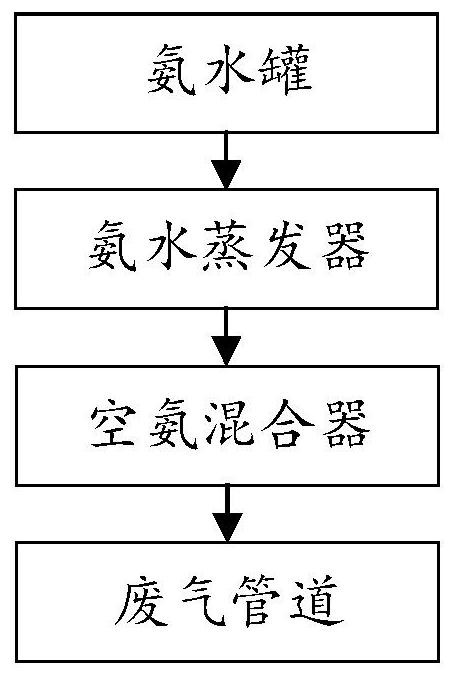

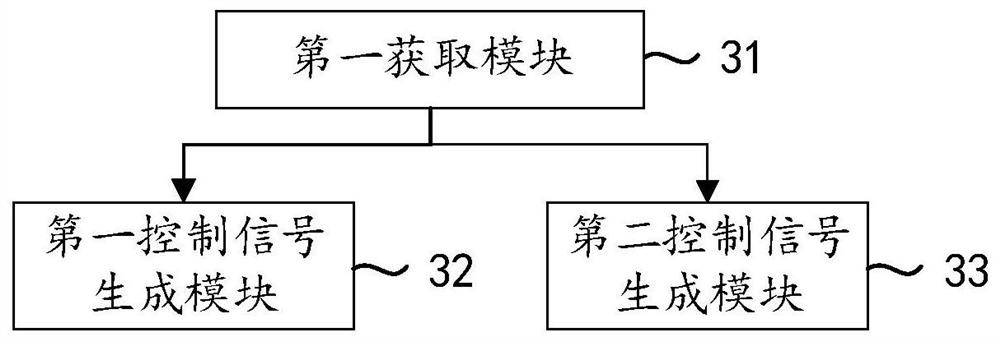

[0052]A SCR denitrifination spray ammonia control method is applied to the SCR denitration spray ammonium system, and the method includes obtaining the first nitrogen oxide content data at the end of the current detection cycle, the exit of the exhaust pipe of the SCR denitration injection; When the first nitrogen oxide content data exceeds the highest preset concentration threshold, the first control signal is generated; the first control signal is used to control the valve of the ammonia water flow regulating valve of the SCR denitration spray in ammonia system at the end time of the current detection cycle. The first preset opening; when the first nitrogen oxide content data does not exceed the lowest pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com