Flour mill

A technology of flour milling and coarse powder, which is applied in the direction of solid separation, sieving, grilling, etc., can solve the problems of dust leakage, complicated process, pollution, etc., achieve the effect of small space occupation, overcome dust leakage, and simple equipment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

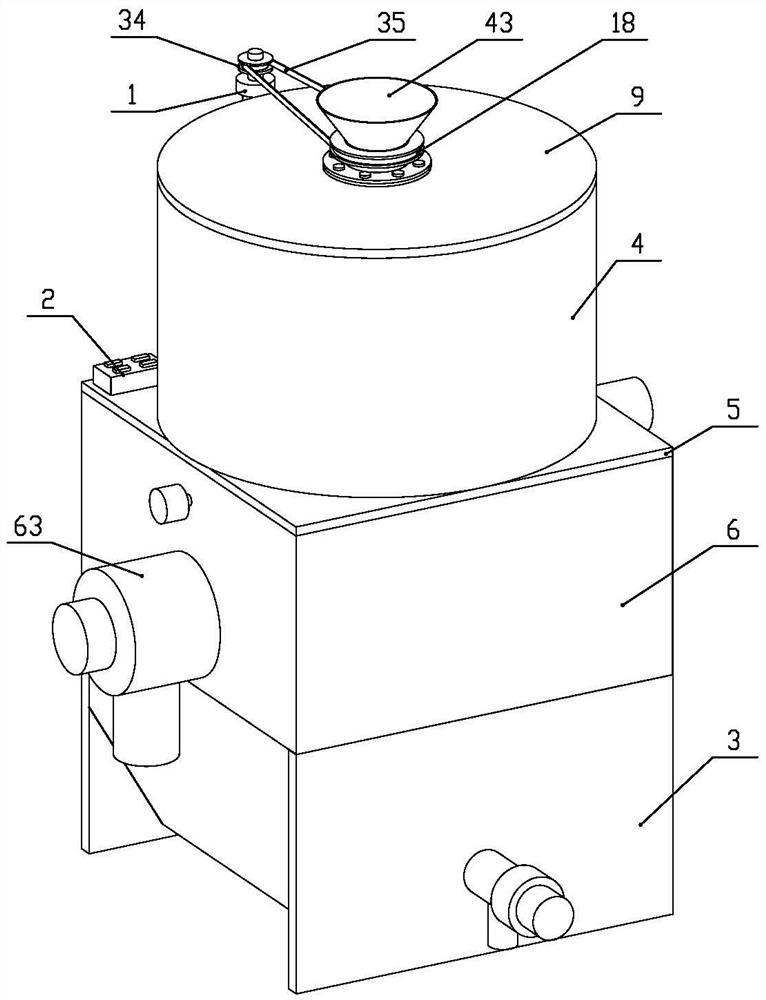

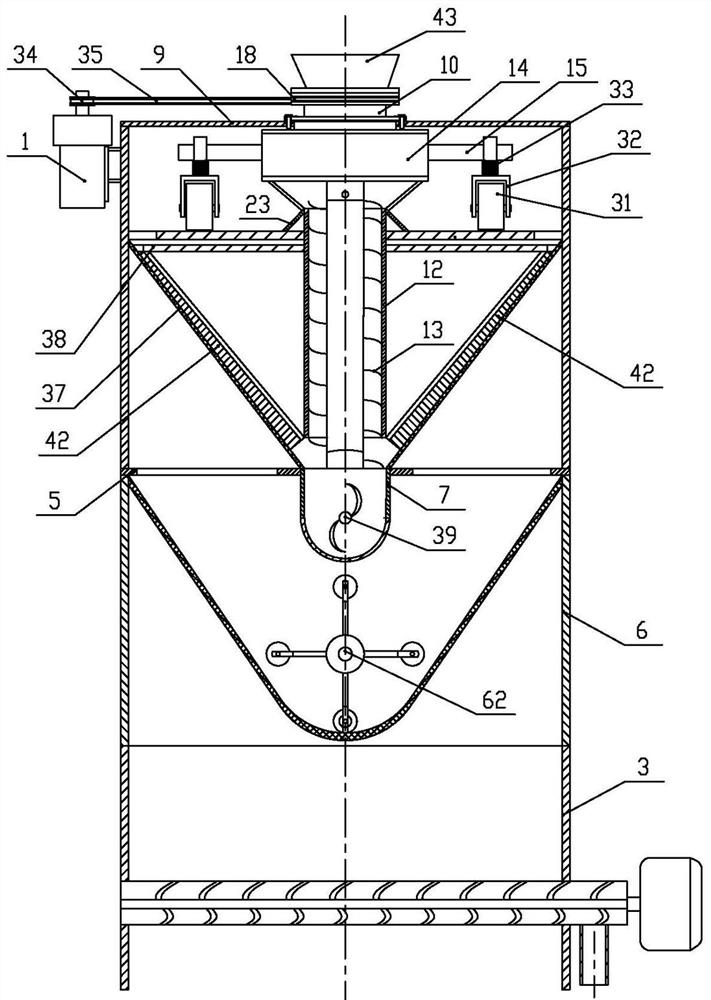

[0038]When the present invention is used to prepare wheat flour and sieve out bran to obtain medium flour and fine flour at the same time, all the above-mentioned components are prepared and connected and assembled before operation. The total height of the present invention is 1580mm, the power of the speed-regulating motor 1 that is adopted is 400 watts, the rotating speed of the speed-regulating motor 1 is 150 revs / min, the outer diameter of the cylinder box 4 is 400mm, and the height is 500mm. The height is 500mm, and the height of square delivery frame box assembly 3 is 420mm, and conical sieve cylinder 37 is 60 purpose square hole sieves, and the powder sieve plate part of agitating type screening box 6 is 100 purpose square hole sieves. Before the grain addition operation of the present invention, close the driving motor of the coarse flour screw conveyor, open the sealing cover on the grain receiving port 43 of the cone, and then connect the external grain addition facil...

Embodiment 2

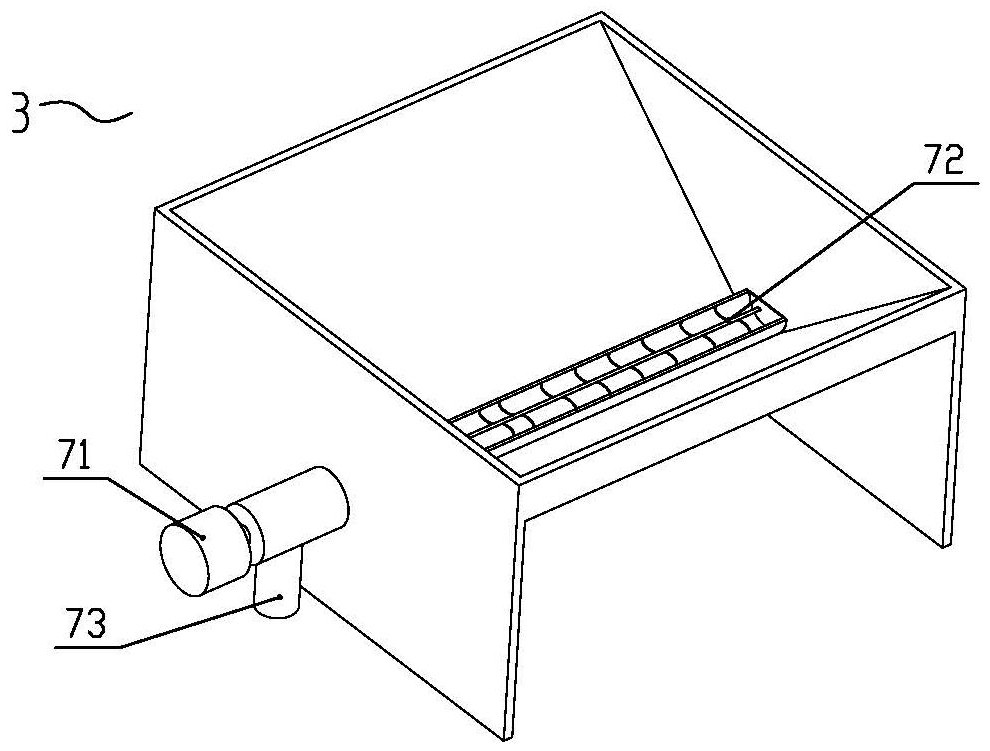

[0040] When the present invention produced fine powder and flour containing bran with wheat, close the drive motor of coarse powder screw conveyor 39, equipment and operation steps are the same as embodiment one; Because the drive motor of coarse powder screw conveyor 39 is closed, wheat contains The bran is crushed and all pass through the conical sieve cylinder 37 and the medium powder outlet 67 of the star-shaped powder unloading valve 63, and the bran-free fine powder sieved by the agitating sieving box 6 is sent by the fine powder screw. The fine powder row pipe 73 of conveyer 72 is discharged, obtains fine powder (fine powder) and the semi-full powder that contains bran.

[0041] As can be seen from the examples, the present invention can integrate crushing and the separation of bran (hull) skin and flour, and overcome the shortcomings of many types of process equipment, many processes, and large space occupation in grain equipment; the grain bran (husk) ), there is no a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com