Device and method for rotatably casting metal ingots

A technology of metal ingot casting and rotary casting, which is applied in the control of molten metal pouring from ladles, metal processing equipment, and equipment for transporting molds, etc. It can solve the problems of easy oxidation and separation of interfaces, quality problems of steel ingots, and pores problem, to achieve the effect of increasing the nucleation rate, reducing the liquid shrinkage, and increasing the degree of supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

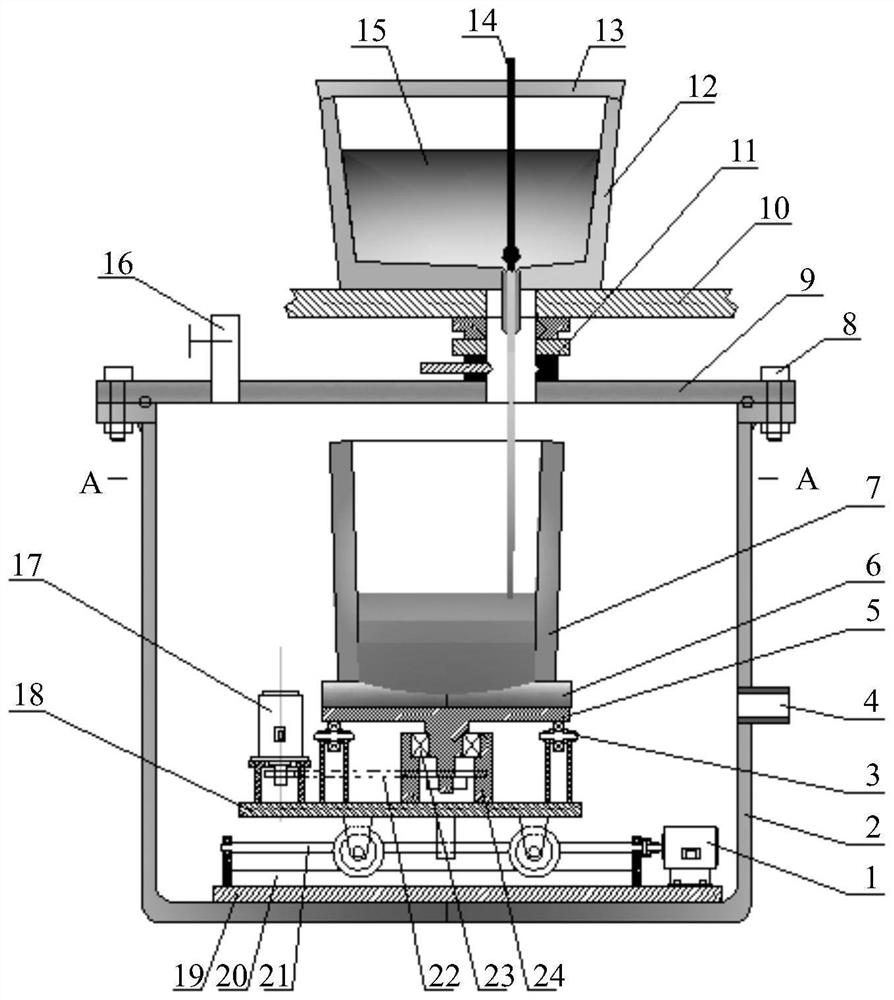

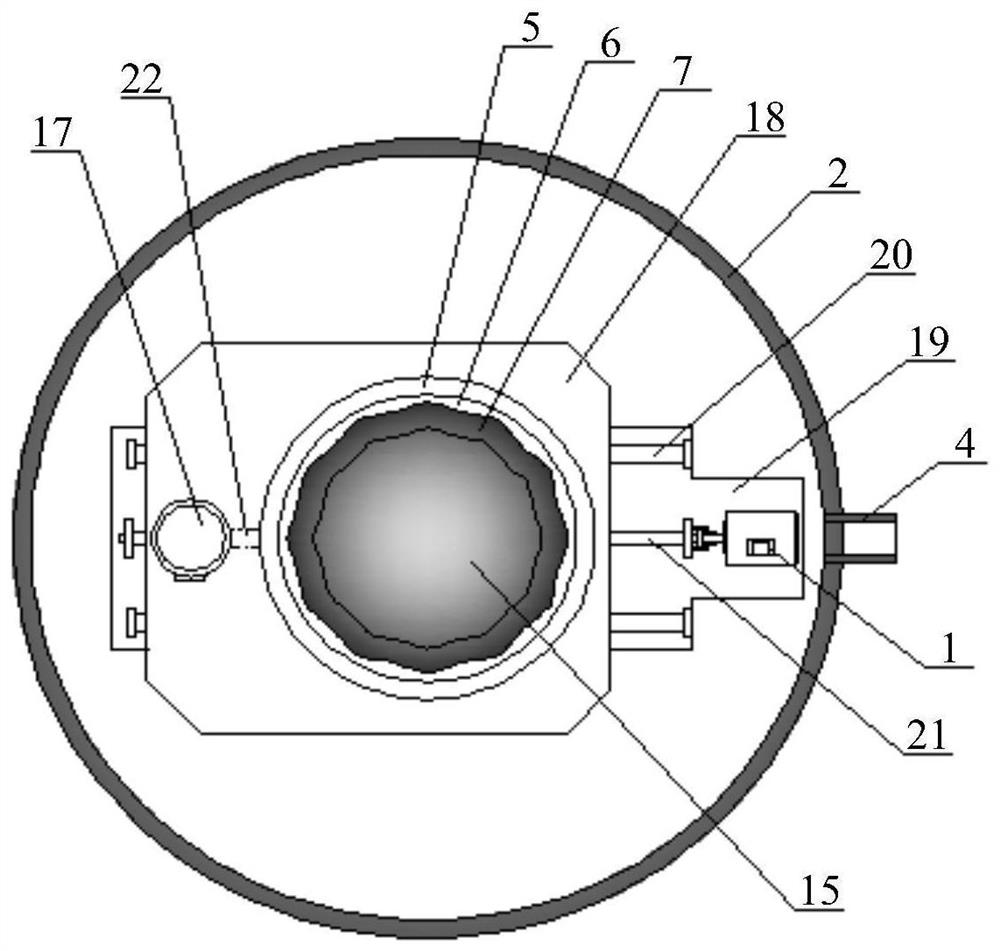

[0030] A device for rotary casting metal ingots, comprising a vacuum protective atmosphere system, a rotary displacement system located inside the vacuum protective atmosphere system, and a casting system located above the vacuum protective atmosphere system;

[0031]The vacuum protective atmosphere system includes a vacuum atmosphere tank body 2, a top cover 9, an air inlet pipe 4, an exhaust pipe 16, a sealing valve plate 11, and a vacuum pumping device and an inert gas supply device positioned outside the vacuum atmosphere tank body; The vacuum atmosphere tank body is welded by steel plates. A top cover is arranged on the top of the vacuum atmosphere tank body. The top cover is provided with a pouring orifice. The sealing valve plate is arranged on the top of the pouring orifice. The top cover and the vacuum atmosphere tank Sealing and fixing methods are adopted between the bodies, such as sealing bolt locking or sealing buckle locking. This embodiment adopts the method of s...

Embodiment 2

[0035] A method for rotary casting metal ingots, using the device of embodiment 1, comprising the steps of:

[0036] a. Evacuate the air in the vacuum atmosphere tank: put the rotary displacement system and the ingot mold into the vacuum atmosphere tank 2, place the ingot mold directly below the pouring orifice, and put the top cover on the vacuum atmosphere tank 2 9. Lock the top cover 9 with the sealing bolt 8, close the exhaust pipe 16, close the sealing valve plate 11; open the air intake pipe 4, open the vacuum pumping device, and vacuumize the vacuum atmosphere tank 2, when the vacuum After the gas in the atmosphere tank 2 is emptied, fill the inert gas into the vacuum atmosphere tank 2 through the inert gas supply device until the pressure in the vacuum atmosphere tank 2 is greater than the external atmospheric pressure, and stop feeding the vacuum atmosphere tank 2. Fill with inert gas.

[0037] b. Hanging the tundish: hang the tundish 12 on the casting platform 10, a...

Embodiment 3

[0045] This embodiment relates to a method for preparing a metal ingot by rotary casting using the device in Embodiment 1. Taking the preparation of a large 16Mn steel ingot with a weight of 85 tons as an example, the specific steps are as follows:

[0046] a. If Figure 1-Figure 2 As shown, first assemble the equipment: place the base plate 19 at the bottom of the vacuum atmosphere tank body 2, then install the traverse track 20 on the base plate 19, and then install the traverse trolley 18, the traverse motor 1 and the traverse transmission mechanism 21, Place the rotating chassis 5 and its transmission mechanism and supporting device on the traversing trolley 18, place the mold bottom 6 and the mold body 7 on the rotating chassis 5, cover the top cover 9 on the vacuum atmosphere tank body 2, and use the sealing bolt 8 Lock it, then move the bottom of the casting platform 10, align the casting opening of the top cover 9 with the casting opening above the casting platform 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com