Polishing disk for quickly polishing surface of flaky diamond crystal and polishing method of polishing disk

A crystal surface, diamond single crystal technology, used in grinding/polishing equipment, abrasive surface adjustment devices, grinding/polishing safety devices, etc., can solve crystal fractures, can not solve the problem of diamond polishing, and there is no large-size single crystal diamond Polishing method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

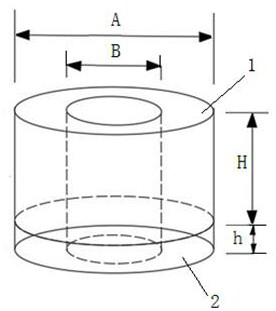

[0031] Firstly, three kinds of polishing discs are made by diamond micropowder with different particle sizes, that is, coarse polishing disc, medium polishing disc and fine polishing disc, such as figure 1 As shown, each polishing disc includes an abrasive body 1 and a base 2, the abrasive body 1 is compositely arranged on the base 2, and the base 2 is a stainless steel disc. The outer diameter A of the grinding body 1 is 350 mm, the inner diameter B is 150 mm, and the thickness H is 30 mm. The base 2 also has an outer diameter of 350 mm, an inner diameter of 150 mm, and a thickness h of 10 mm. The three kinds of polishing disks are only different in the particle size of the diamond powder used in the grinding body 1. The particle size of the diamond powder is 0.5 micron to 36 micron.

[0032] 1. Preparation of Coarse Polishing Discs

[0033] Making grinding body: Mix diamond powder with a particle size of 22-36 microns and synthetic resin according to the mass ratio of 1:10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com